Clamping and machining method capable of guaranteeing machining accuracy of aluminum profile frame

A technology of processing accuracy and processing method, which is applied in the direction of metal processing equipment, metal processing machine parts, clamping, etc., and can solve the problems of tolerance, different sizes, high scrap rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

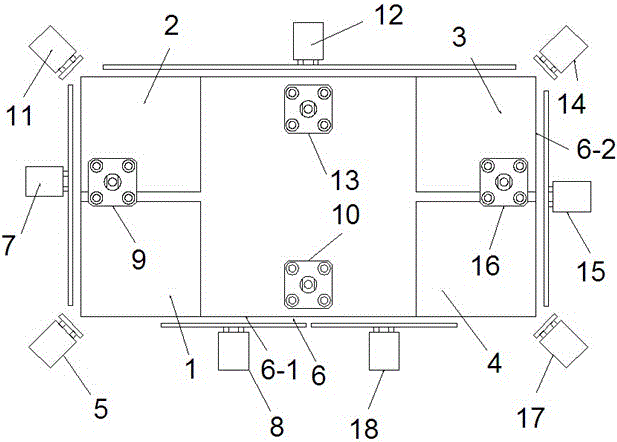

[0069] Such as Figure 1 to Figure 4 As shown, the clamping and processing method to ensure the processing accuracy of the aluminum profile frame is to first clamp the right angle of the rectangular aluminum profile frame 6 and cut the X-direction aluminum profile frame strip 6-1 and the Y-direction aluminum profile frame strip at the right angle. 6-2 Half the length, and then respectively clamp and cut the remaining three right angles of the rectangular aluminum profile frame 6 to complete the cutting process of the entire rectangular aluminum profile frame 6.

[0070] Including the following steps:

[0071] Step 1, placing the rectangular aluminum profile frame 6 on the processing platform of the CNC machining center and ensuring that the abutting block on the processing platform is located in the rectangular aluminum profile frame 6;

[0072] Step 2, clamping the first right-angle part of the aluminum profile frame;

[0073] Step 3, cutting and processing the aluminum pro...

Embodiment 2

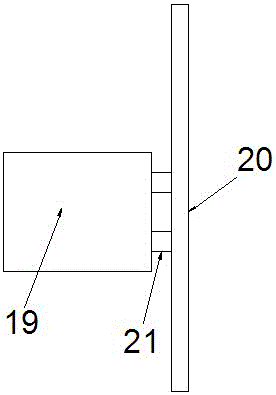

[0118] The difference from Embodiment 1 is that, as Figure 5 Shown: The shape of the abutment block is "L".

Embodiment 3

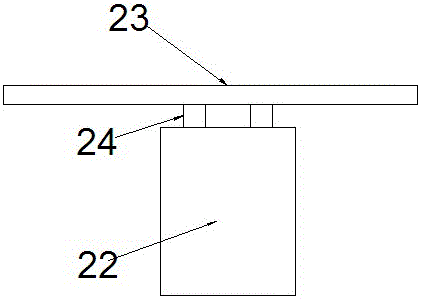

[0120] The difference from Embodiment 1 is that, as Image 6 As shown: the abutting block is a rectangular block, slightly smaller in size than the frame 6 of the rectangular aluminum profile to be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com