Automatic positioning clamping mechanism for feeding and discharging materials in bell-shaped shell defect-detection/cleaning integrated machine

An automatic positioning and clamping mechanism technology, applied in the direction of chuck, manipulator, material magnetic variable, etc., can solve problems such as complex structure, unstable air pressure, and unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

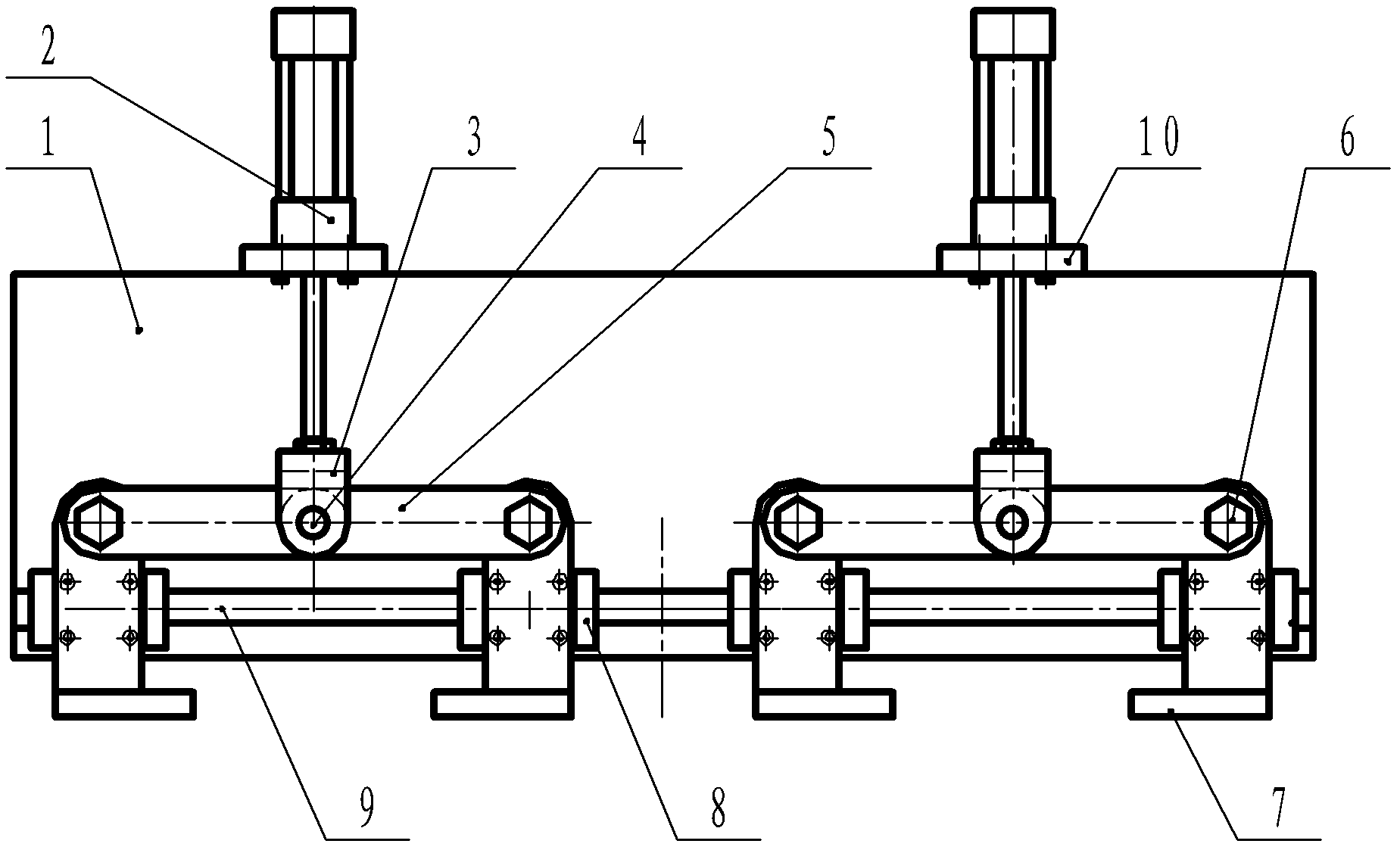

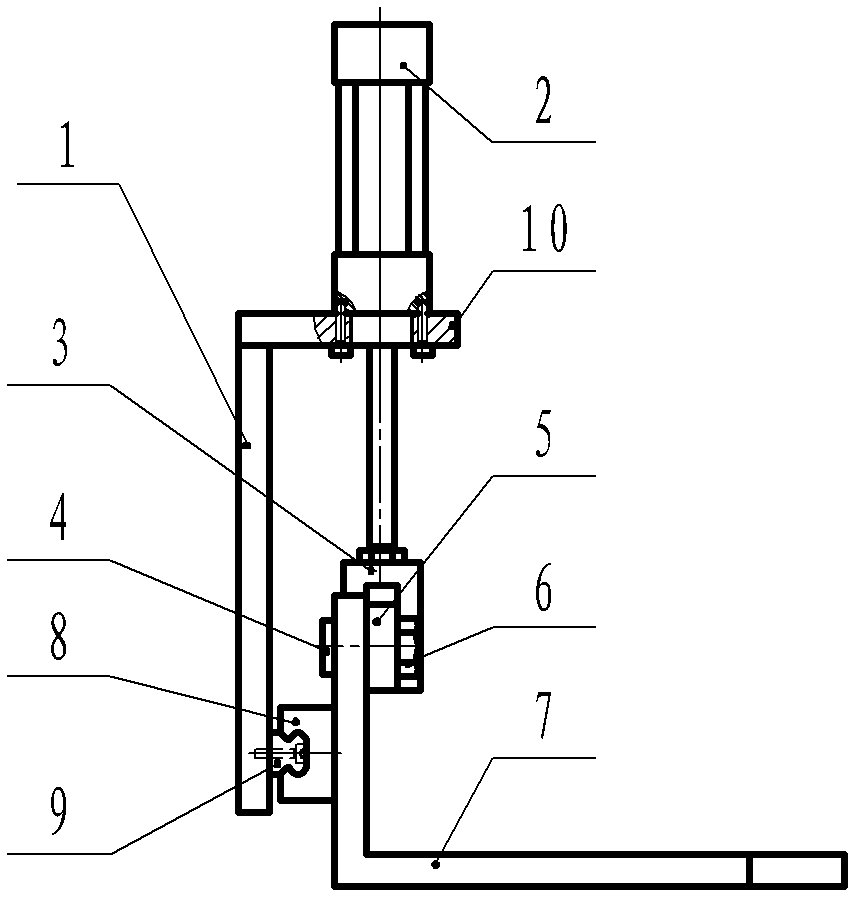

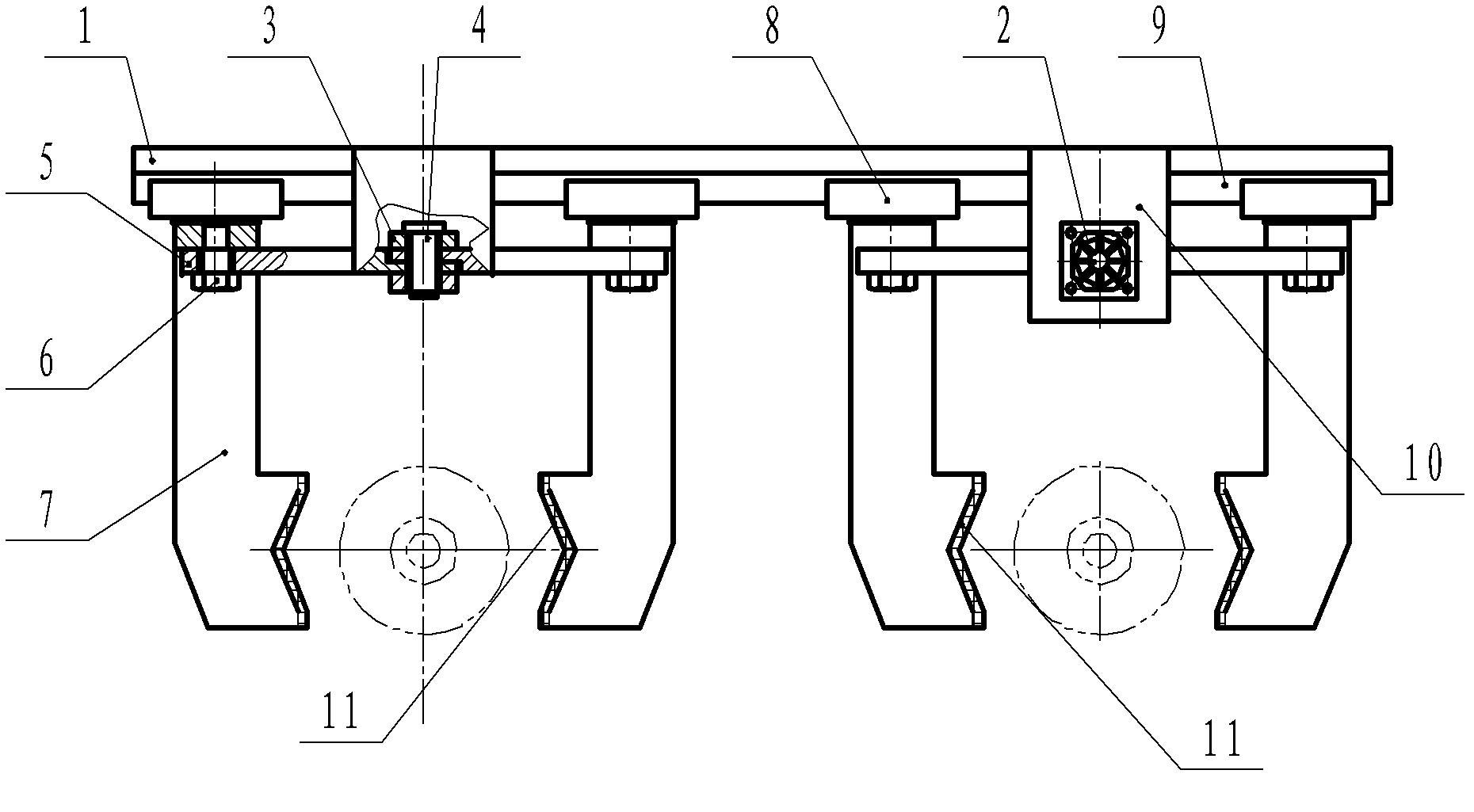

[0015] The present invention is described in detail below in conjunction with the accompanying drawings:

[0016] The invention includes an electrical control system in an integrated machine, a gas source supply device, and stations for feeding, pre-cleaning, magnetic particle inspection, demagnetization, cleaning, drying, and blanking. The left and right sides of the inspection station are respectively provided with There is an integrated chain conveying device, and the magnetic particle inspection station is equipped with a robot automatic loading and unloading device; the bell-shaped shell workpiece chain conveying device is transported from the loading station to the magnetic particle inspection station, and is automatically carried out by the robot. Longitudinal and lateral transfer to the magnetic particle inspection station. After the workpiece is inspected by the magnetic particle inspection station, it is moved to the subsequent demagnetization and cleaning conveyor li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com