Full-automatic PCB (printed circuit board) positioning clamp

A PCB board and positioning fixture technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of time-consuming positioning and clamping, low working efficiency of the entire production line, poor stability, etc., to improve production efficiency and reliability. And the effect of convenient positioning and clamping, fast and accurate positioning and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

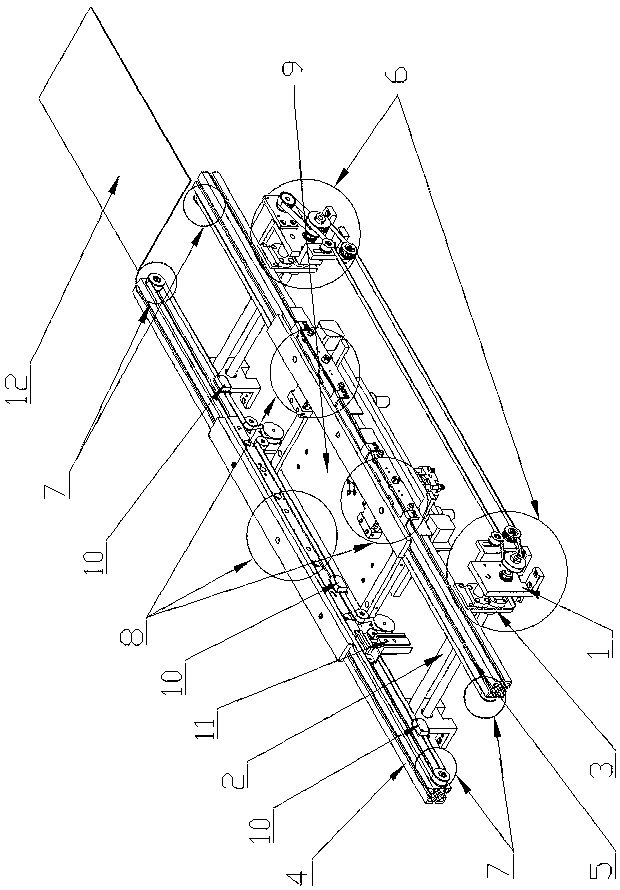

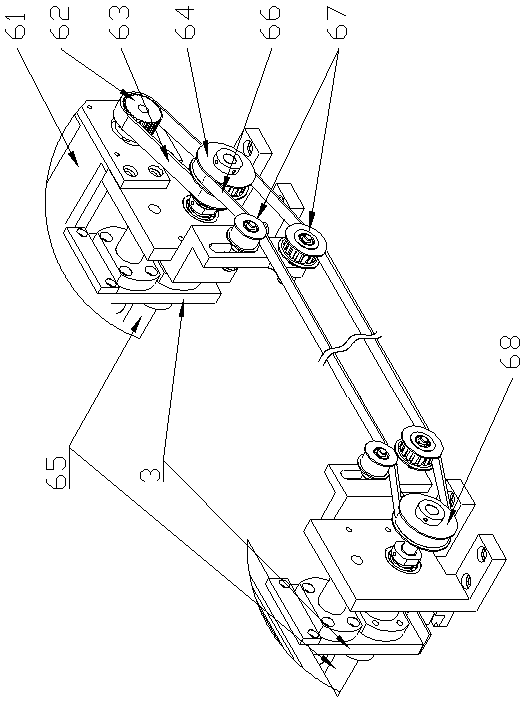

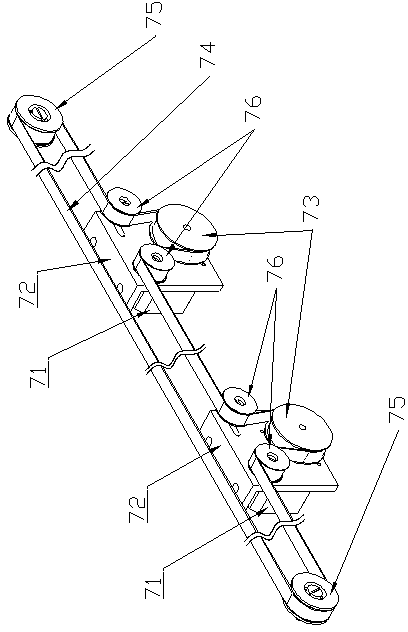

[0017] The structure and operation steps of the fully automatic PCB board positioning jig of the present invention will be described in detail below with reference to the accompanying drawings.

[0018] The fully automatic PCB board positioning fixture of the present invention, the fully automatic PCB board positioning fixture of the present invention, comprises a support base 1, a support rod 2, a sliding support plate 3, a fixed side rail 4, a moving side rail 5, a width adjustment mechanism 6, a conveying Mechanism 7, clamping mechanism 8, top plate mechanism 9, detection mechanism 10 and positioning mechanism 11, wherein the support rod 2 and the width adjustment mechanism 6 are installed on the opening provided on the side of the support base 1, and the fixed side rail 4 is fixed on On the support seat 1, the sliding support plate 3 is slidably connected with the support rod 2, and the mobile side rail 5 is fixed on the sliding support plate 3, the sliding support plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com