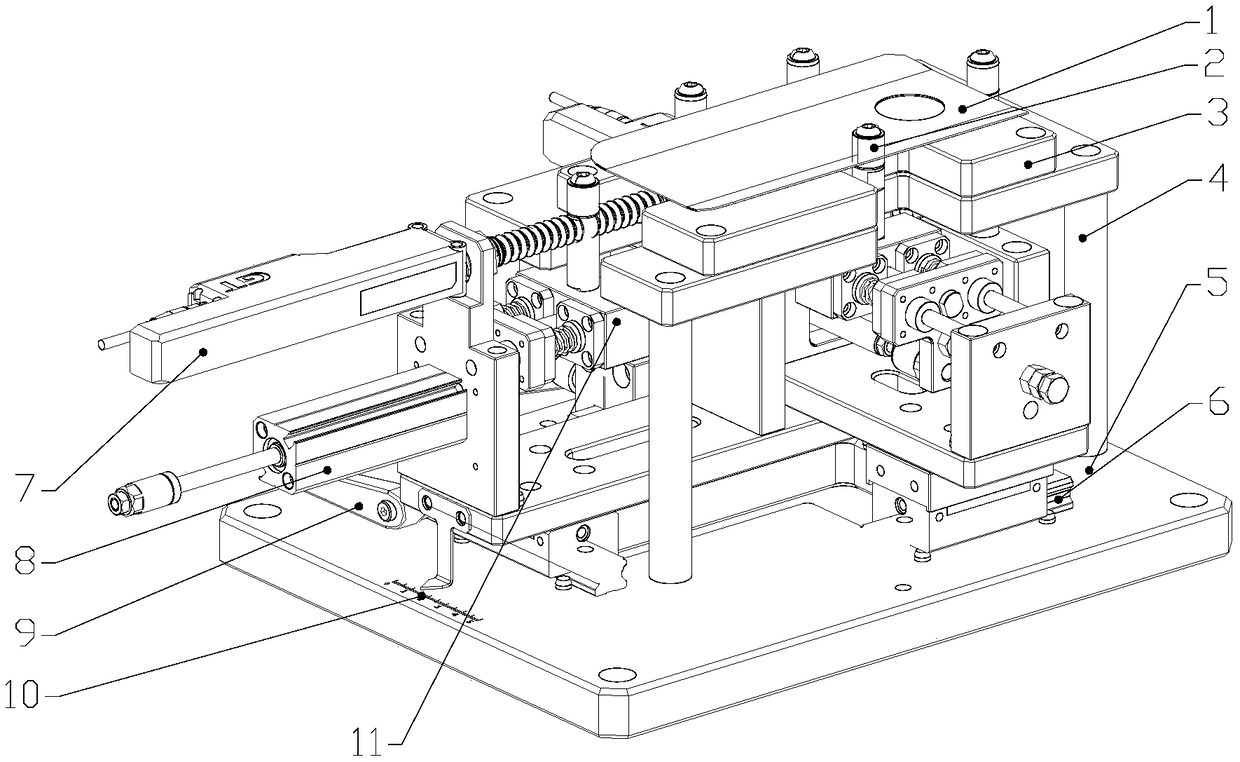

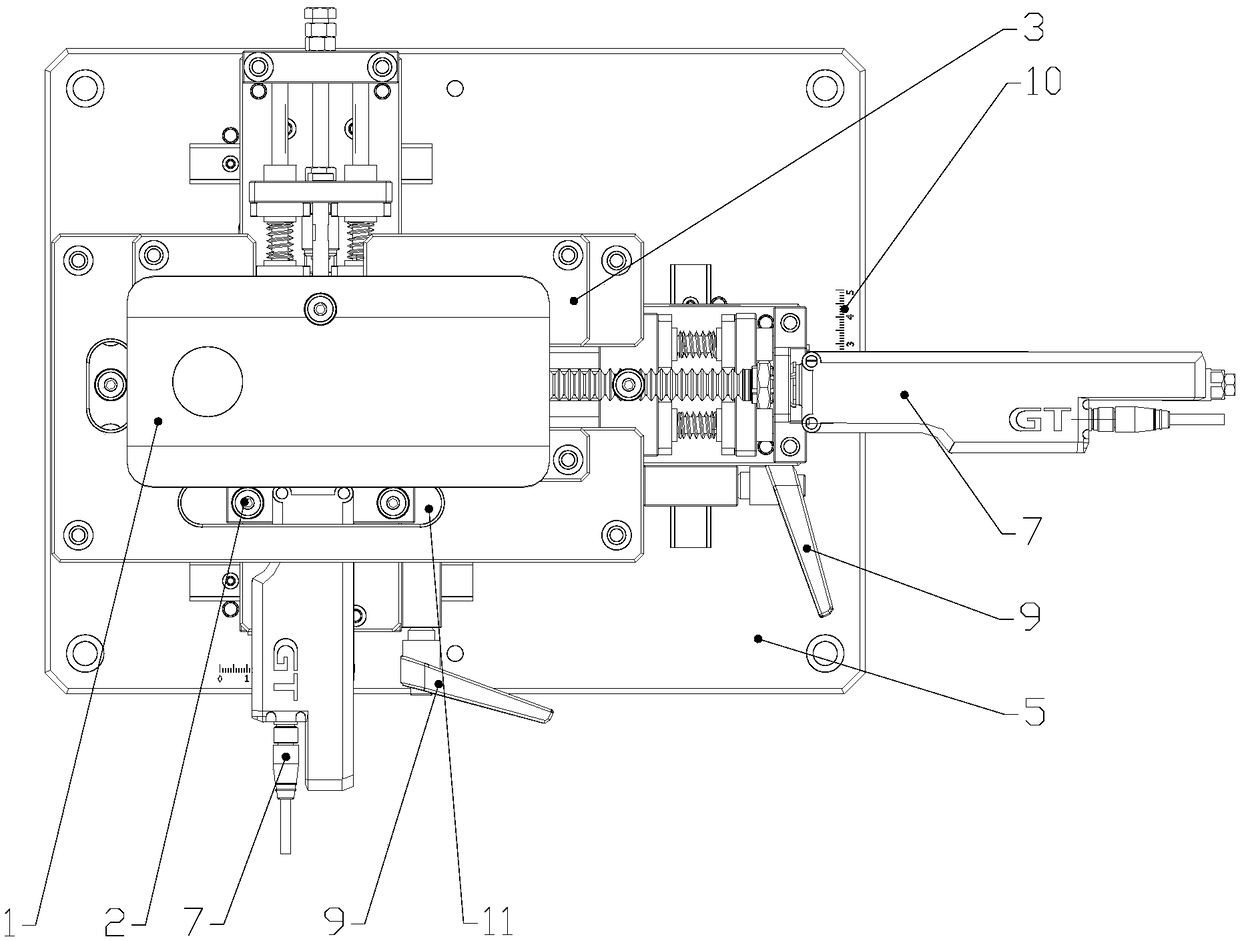

Laser carving accurate measurement positioning jig

A positioning fixture and precise technology, applied in the field of laser engraving, can solve problems such as positioning, clamping, size measurement, and insufficient applicability at the same time, and achieve the effects of precise positioning and clamping, cost saving, and improved yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

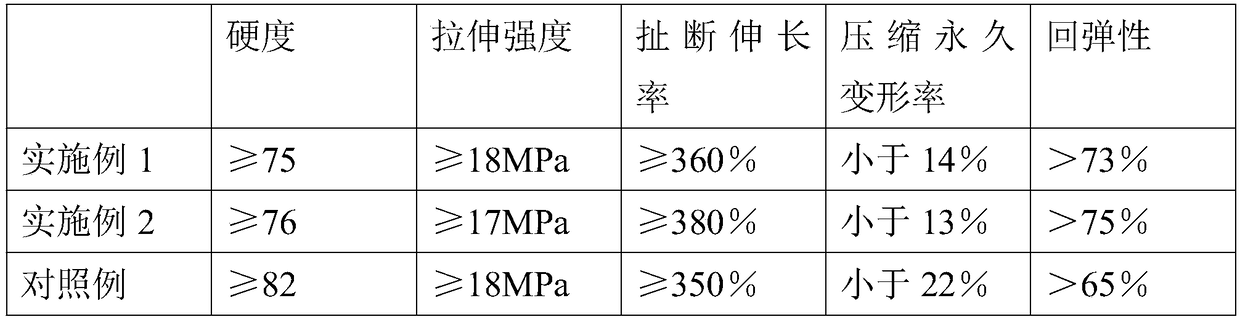

Embodiment 1

[0034] Example 1: Constant viscosity natural glue 10%, zinc oxide 0.2%, stearic acid 0.6%, antioxidant RD 0.2%, boron trioxide 1%, carbon black N5502%, carbon black N3302%, polymeric sulfur 1% , N-oxydiethylene-2-benzothiazole sulfenamide 3%, tetramethylthiuram disulfide 2.3%, scorch inhibitor CTP 1.2%, disodium hydrogen phosphate 1%, corn starch 10% , Polyvinyl alcohol 3%, vinyl acetate 2%, the rest is water.

Embodiment 2

[0035] Example 2: Constant viscosity natural glue 12%, zinc oxide 0.3%, stearic acid 0.8%, antioxidant RD 0.3%, boron trioxide 3%, carbon black N5503%, carbon black N3303%, polymeric sulfur 1.5% , N-oxydiethylene-2-benzothiazole sulfenamide 6%, tetramethylthiuram disulfide 3%, scorch inhibitor CTP 1.8%, disodium hydrogen phosphate 2%, corn starch 13% , Polyvinyl alcohol 5%, vinyl acetate 6%, the rest is water.

[0036] The preparation method of high elastic rubber block includes the following steps:

[0037] Step 1: Put water and disodium hydrogen phosphate into a stirring tank according to the ratio, and heat to 60°C under constant stirring, so that the disodium hydrogen phosphate solution is completely dissolved, and the corn starch and disodium hydrogen phosphate solution are mixed thoroughly according to the ratio Add to the reactor, the material is stirred in the reactor and the temperature is increased to 70-80°C. When the water content is reduced to less than 20%, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com