Circular pipe butt joint welding test rotating device and operation method thereof

A technology of welding test and rotating device, applied in the field of steel structure, can solve the problems of poor use effect and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

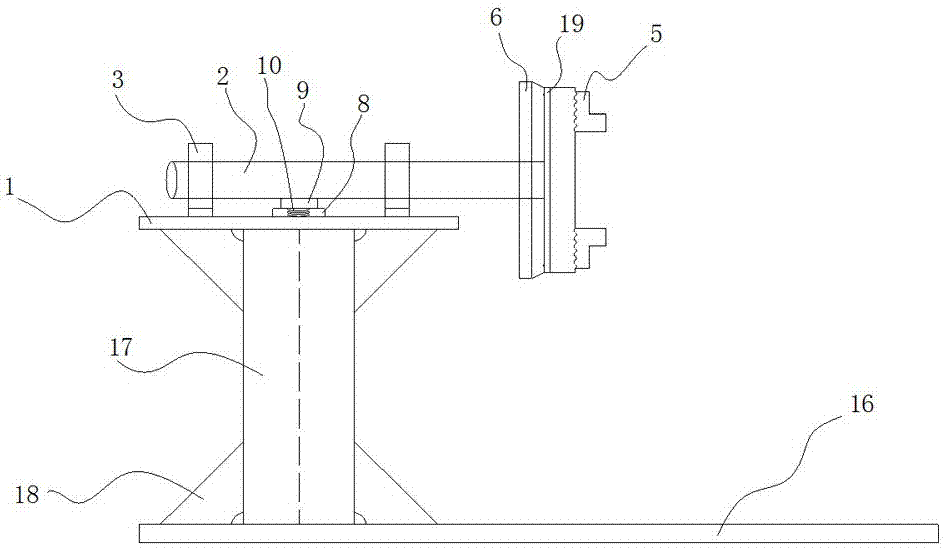

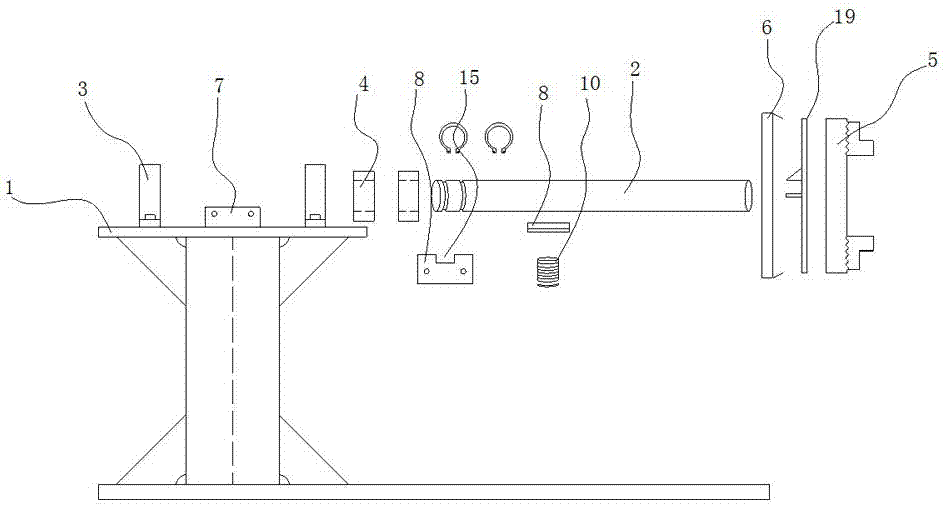

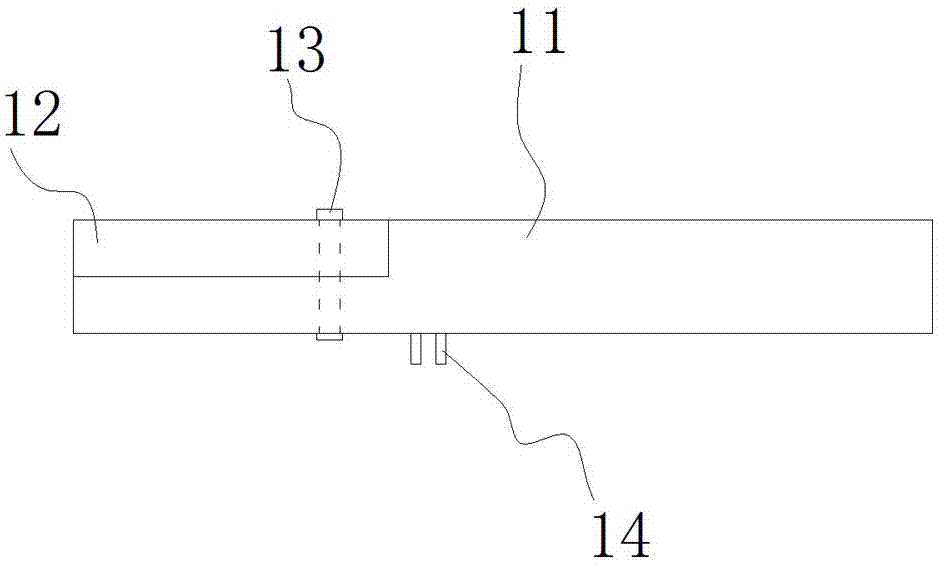

[0035] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a circular pipe butt welding test rotating device includes a base assembly and an operating platform assembly, and the upper part of the base assembly is provided with an operating platform assembly;

[0036] The operating platform assembly includes a platform 1, and a horizontally distributed shaft 2 is arranged on the top of the platform 1, and the shaft 2 is movable and positioned with the platform 1 through a pair of spaced apart bearing seats 3, A bearing 4 is provided between the bearing seat 3 and the shaft 2, and a welding manual chuck 5 is provided at the outer end of the shaft 2, and the welding manual chuck 5 drives the shaft 2 to rotate by turning the hand wheel 6.

[0037] The table 1 is provided with a fixed plate 7, the fixed plate 7 is provided with an insulating plate 8, and the upper part of the insulating plate 8 is provided with a grounding plate 9 in contact with the shaft 2. A spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com