Free-cutting steel containing relatively high content tin and preparation method

A free-cutting steel, high content technology, applied in the field of metallurgy, to achieve high economic and environmental benefits, high melting point, high hot rolling process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The process route that each embodiment adopts is:

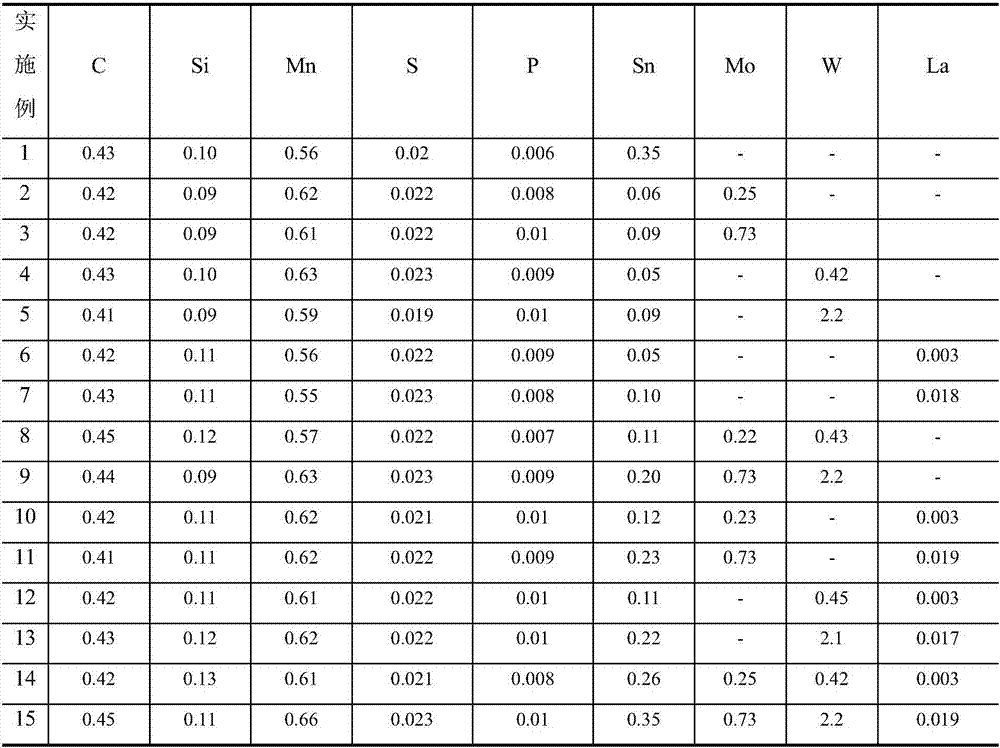

[0015] Steelmaking (converter or electric furnace) → refining (LF, VD, RH) → continuous casting → hot rolling. Among them, the alloy elements Mo, W, and rare earth element La in each embodiment are added during the refining process, and are added individually or in combination according to the difference in Sn content, as shown in Table 1.

[0016] Table 1 shows the main chemical components and their mass percentages of each embodiment of the present invention, and iron and unavoidable impurities are not listed in Table 1.

[0017] Each embodiment main chemical composition of table 1 and mass percentage (%) thereof

[0018]

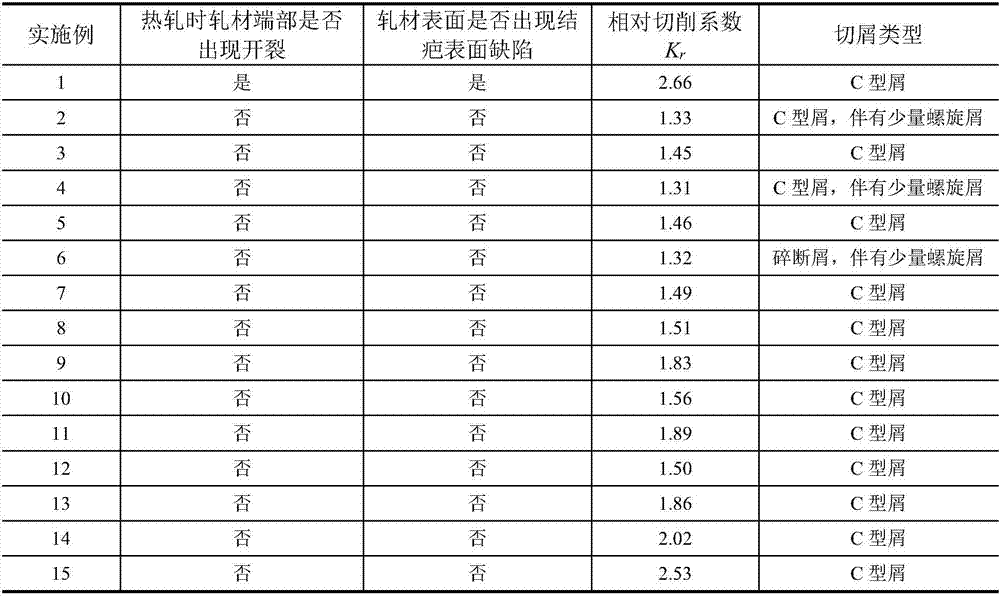

[0019] In terms of the continuity and stability evaluation of the hot rolling process, it is mainly to make statistics on whether there is cracking at the end of the rolled material in each embodiment during hot rolling. The numbered embodiment corresponds to the end of the rolled material. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com