Method for refining indium reverse extraction liquid and gathering valuable metal and application

A valuable metal and stripping solution technology, applied in the field of indium recovery, can solve the problems of low indium replacement efficiency and direct recovery rate, high consumption of zinc powder and sponge indium, and increased production costs, so as to achieve low production costs and easy operation. Convenient and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

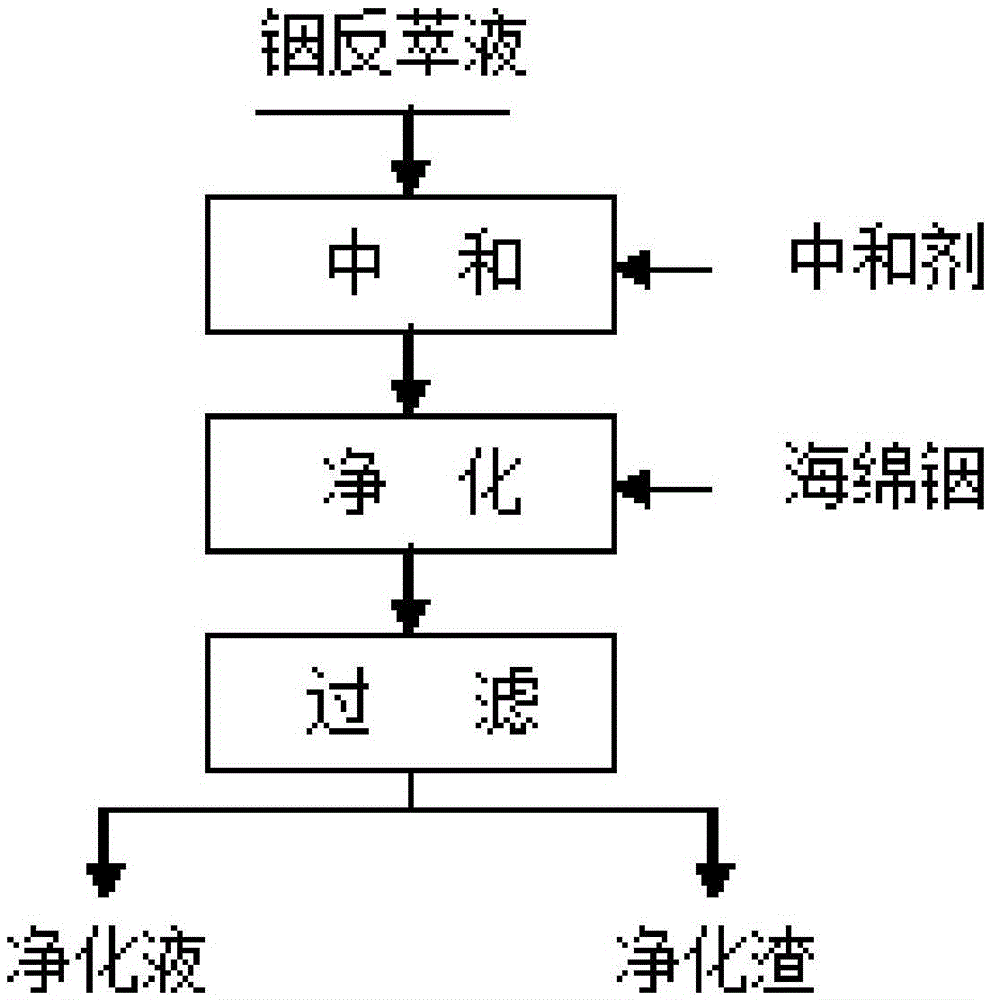

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the mass-volume concentration (both in ion state) of the main components of the indium stripping solution is: In76.18g / L, Fe10.25g / L, Bi1.58g / L, Sn0.83g / L, As1.52g / L, Sb0.037g / L; HCl is 135.28g / L.

[0044] Step A: Neutralizing agent Na 2 CO 3 Add it to the purification tank with the indium stripping solution, stir to make it react completely, Na 2 CO 3 The addition amount is to make the mass-volume concentration of hydrochloric acid in the indium stripping solution be 50g / L. Step B: In the static state of stirring, add the reducing agent sponge indium to the solution system in step A at a temperature of 50°C at one time, and react for 12 hours. During the above process, the gas H 3 As produced less, to obtain a reducing solution; wherein, the amount of sponge indium is the Fe in the solution 3+ , AsO 3 3- 、 Bi 3+ 、Cu 2+ , Sn 4+ and Sn 2+ respectively reduced to Fe 2+ , As, Bi, Cu and Sn, etc. 3.5 times the theoretical amount.

[0045] St...

Embodiment 2

[0047] In this embodiment, the mass-volume concentration (both in ion state) of the main components of the indium stripping solution is: In76.18g / L, Fe10.25g / L, Bi1.58g / L, Sn0.83g / L, As1.52g / L, Sb0.037g / L; HCl is 135.28g / L.

[0048] Step A: Neutralizing agent NaHCO 3 Add it to the purification tank with the indium stripping solution, stir to make it react completely, NaHCO 3 The addition amount is to make the mass-volume concentration of hydrochloric acid in the indium stripping solution be 30g / L.

[0049] Step B: In the static state of stirring, add the reducing agent sponge indium to the solution system in step A at a temperature of 20°C at one time, and react for 3 hours to obtain the reducing solution; wherein, the amount of the sponge indium is the amount of Fe in the solution 3+ , AsO 3 3- 、 Bi 3+ 、Cu 2+ , Sn 4+ and Sn 2+ respectively reduced to Fe 2+ , As, Bi, Cu and Sn, etc. 2.0 times the theoretical amount.

[0050] Step C: Filter the reducing solution obtai...

Embodiment 3

[0052] In this embodiment, the mass-volume concentration (both in ion state) of the main components of the indium stripping solution is: In76.18g / L, Fe10.25g / L, Bi1.58g / L, Sn0.83g / L, As1.52g / L, Sb0.037g / L; HCl is 135.28g / L.

[0053] Step A: Add the neutralizing agent NaOH into the purification tank containing the indium stripping solution, stir to make the reaction complete, and the amount of NaOH added is such that the mass-volume concentration of hydrochloric acid in the indium stripping solution is 40 g / L.

[0054] Step B: In the static state of stirring, add the reducing agent sponge indium to the solution system in step A at a temperature of 40°C at one time, and react for 8 hours to obtain the reducing solution; wherein, the amount of the sponge indium is the amount of Fe in the solution 3+ , AsO 3 3- 、 Bi 3+ 、Cu 2+ , Sn 4+ and Sn 2+ respectively reduced to Fe 2+ , As, Bi, Cu and Sn, etc. 3.0 times the theoretical amount.

[0055]Step C: Filter the reducing solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com