Hard disk drive spindle motor component of composite coating and composite coating method thereof

A technology of hard disk drive and composite coating, which is applied in the direction of magnetic circuit rotating parts, manufacturing motor generators, coatings, etc. Excellent anti-corrosion properties and the effect of reducing purity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

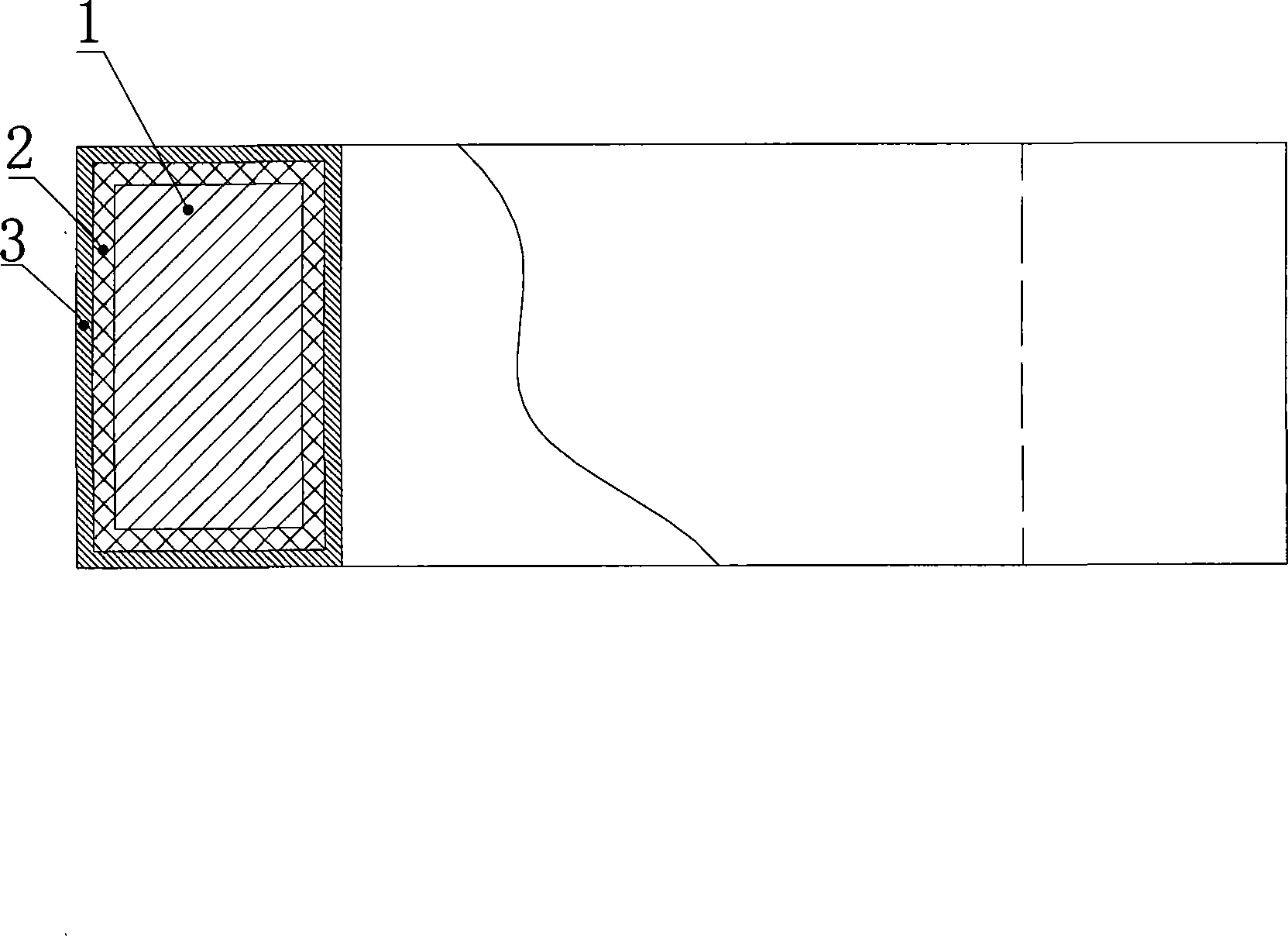

[0021] A composite coated hard disk drive spindle motor magnet, comprising a motor magnet substrate 1, coated with a composite coating on the substrate 1, the composite coating consists of an inner electrophoretic coating 2 and an outer spray coating 3 The weight percentage of tin in the electrophoretic coating 2 is 225~300ppm, wherein the tin is composed of organic tin and inorganic tin, and the weight percentage of organic tin in the electrophoretic coating is 50ppm; the weight of tin in the spray coating 3 The percentage is 26-50ppm.

[0022] The composite coating method of the hard disk drive spindle motor magnet of the composite coating comprises the following process steps:

[0023] A. Coating an electrophoretic coating on the surface of the motor magnet substrate;

[0024] The weight percent of tin in the electrophoretic paint aqueous solution that adopts during electrophoresis is 45~60ppm, and wherein the weight percent of organotin is 10ppm, in order to satisfy the t...

Embodiment 2

[0030] A composite coated hard disk drive spindle motor magnet, comprising a motor magnet substrate 1, coated with a composite coating on the substrate 1, the composite coating consists of an inner electrophoretic coating 2 and an outer spray coating 3 The weight percentage of tin in the electrophoretic coating 2 is 140~225ppm, wherein the tin is composed of organic tin and inorganic tin, and the weight percentage of organic tin in the electrophoretic coating is 30ppm; the tin in the spray coating 3 The weight percentage is not more than 26ppm.

[0031] The composite coating method of the hard disk drive spindle motor magnet of the composite coating comprises the following process steps:

[0032] A. Coating electrophoretic coating on the surface of the motor magnet;

[0033] The weight percent of tin in the electrophoretic paint aqueous solution that adopts during electrophoresis is 28~45ppm, and wherein the weight percent of organotin is 6ppm, in order to satisfy the tin of ...

Embodiment 3

[0039] A composite coated hard disk drive spindle motor magnet, comprising a motor magnet substrate 1, coated with a composite coating on the substrate 1, the composite coating consists of an inner electrophoretic coating 2 and an outer spray coating 3 The weight percentage of tin in the electrophoretic coating 2 is 60~140ppm, wherein the tin is composed of organic tin and inorganic tin, and the weight percentage of organic tin in the electrophoretic coating is 20ppm; the tin in the spray coating 3 The weight percentage is not more than 20ppm.

[0040] The composite coating method of the hard disk drive spindle motor magnet of the composite coating comprises the following process steps:

[0041] A. Coating electrophoretic coating on the surface of the motor magnet;

[0042] The weight percent of tin in the electrophoretic paint aqueous solution that adopts during electrophoresis is 12~28ppm, and wherein the weight percent of organotin is 4ppm, in order to satisfy the tin of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com