Stirring device

A technology of stirring device and stirring paddle, which is applied to mixers with rotating stirring devices, transportation and packaging, mixers, etc. The effect of increasing tin content, improving production efficiency and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with each accompanying drawing.

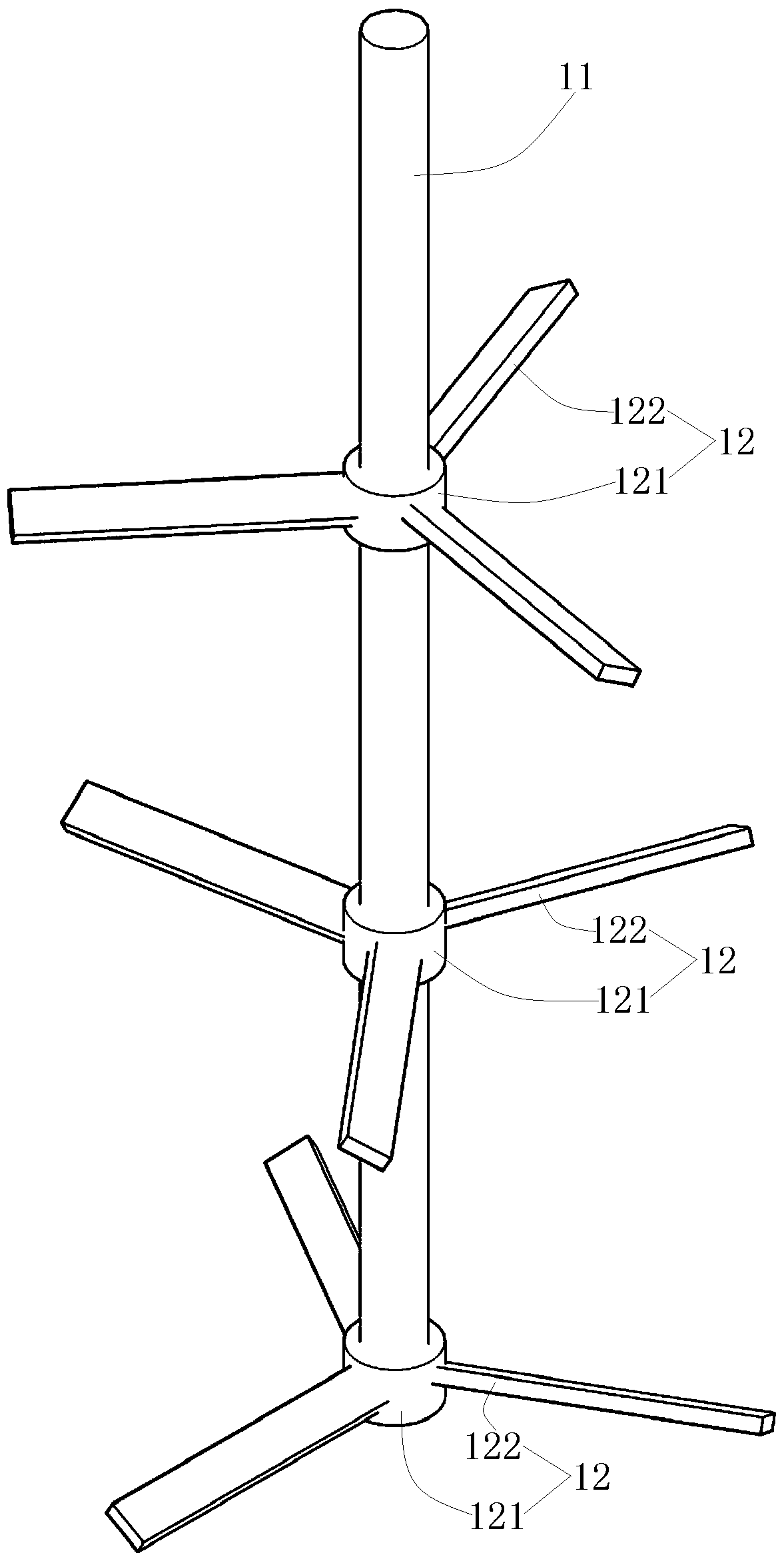

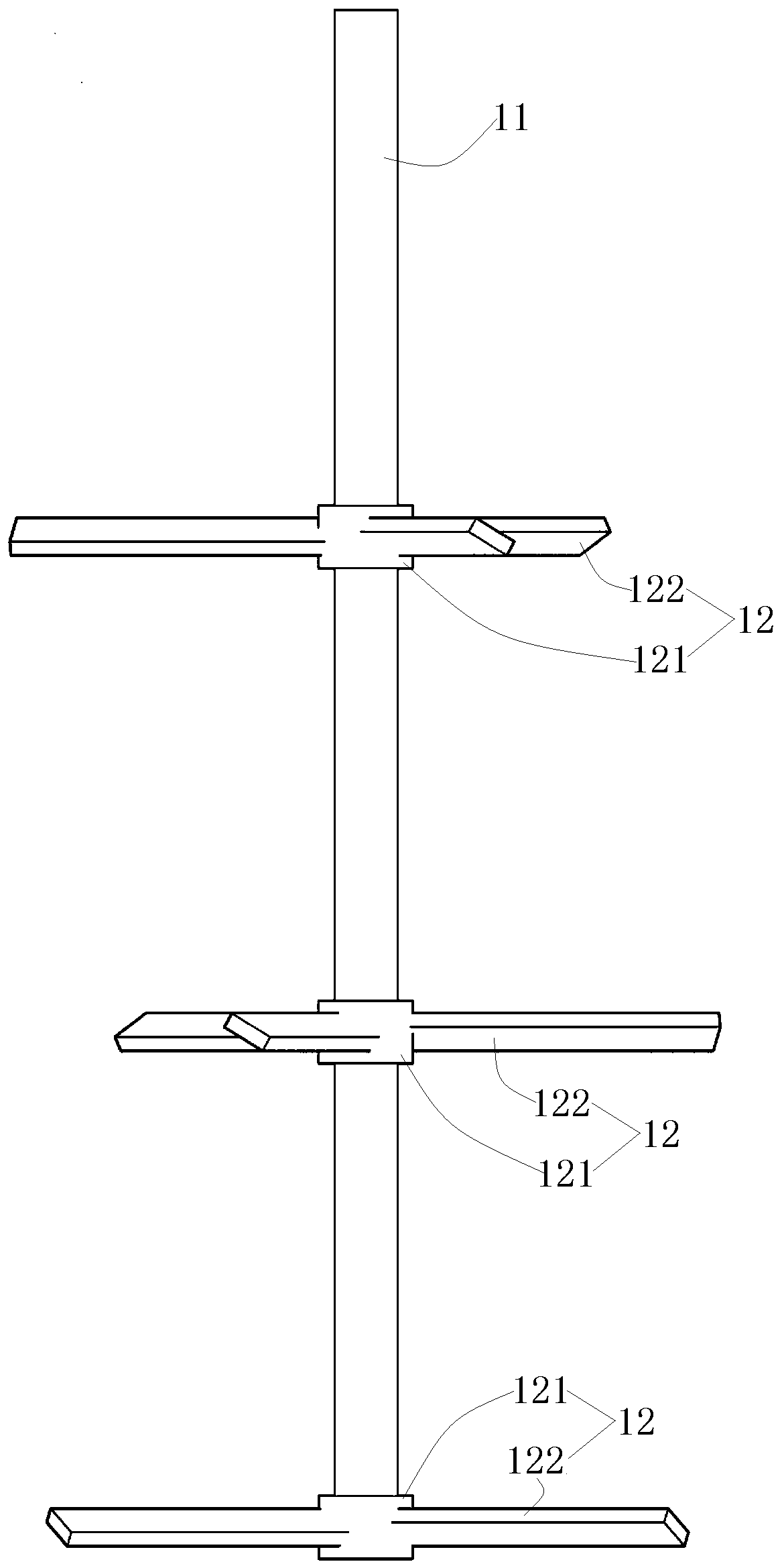

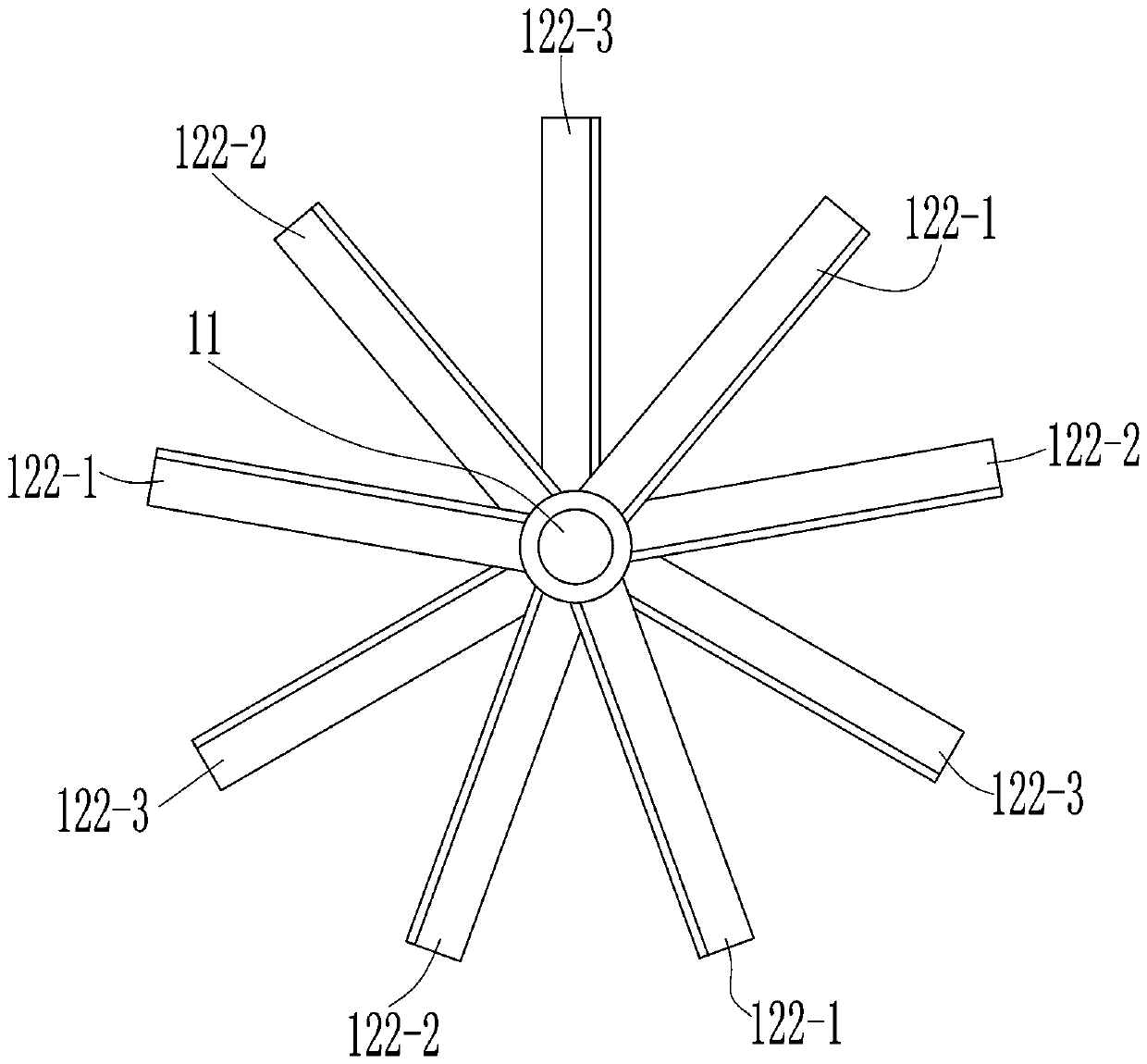

[0025] see Figure 1 to Figure 6 , a stirring device, applied to the reaction kettle in the treatment of tin stripping wastewater, the stirring device includes a main shaft 11 and at least two stirring paddles 12; the stirring paddles 12 include a cylindrical part 121 with a central through hole 1211 and three paddles 122, the three paddles 122 are uniformly fixed on the outer peripheral surface 1212 of the cylindrical portion 121, that is to say, the angle between the adjacent paddles 122 of each stirring paddle 12 is 120° °; the central through hole 1211 of the cylindrical portion 121 of each stirring paddle 12 is respectively inserted and fixed on the main shaft 11, and a certain distance is spaced between two adjacent stirring paddles 12 on the main shaft 11, and the distance is based on The actual situation is determined, mainly determined by the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com