Stanniferous martensitic stainless steel with excellent performance and manufacturing method thereof

A martensitic stainless steel and manufacturing method technology, applied in the field of metallurgical materials, can solve the problems of no application, improve performance, etc., achieve the effects of excellent hardness, improved corrosion resistance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further elaborated below in conjunction with specific examples. It should be clear that these examples are only used to describe the specific implementation of the present invention, and are not intended to constitute any limitation on the protection scope of the present invention.

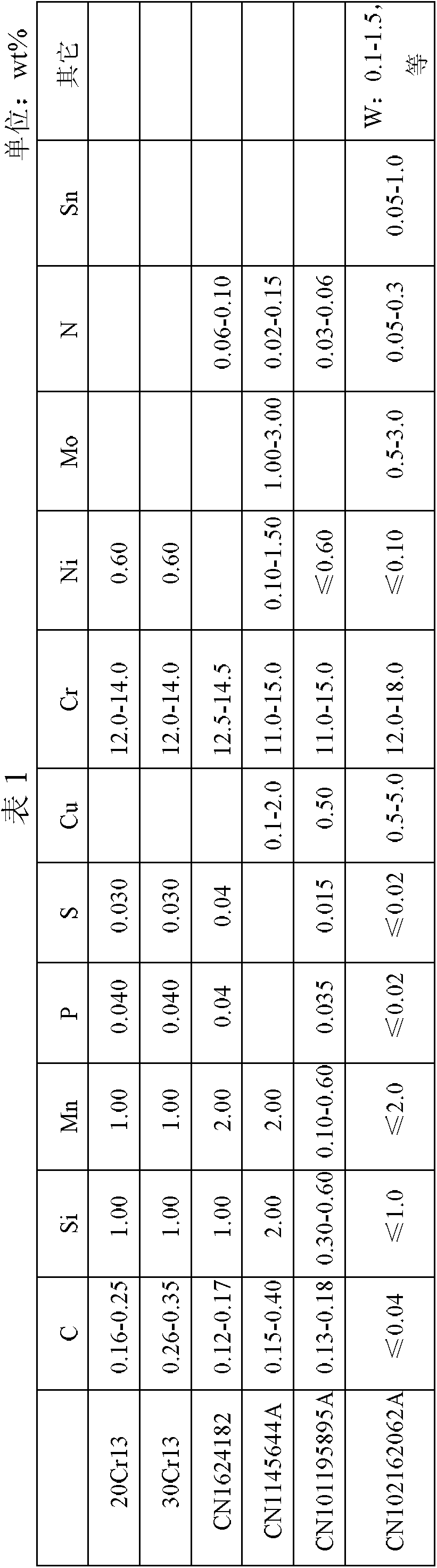

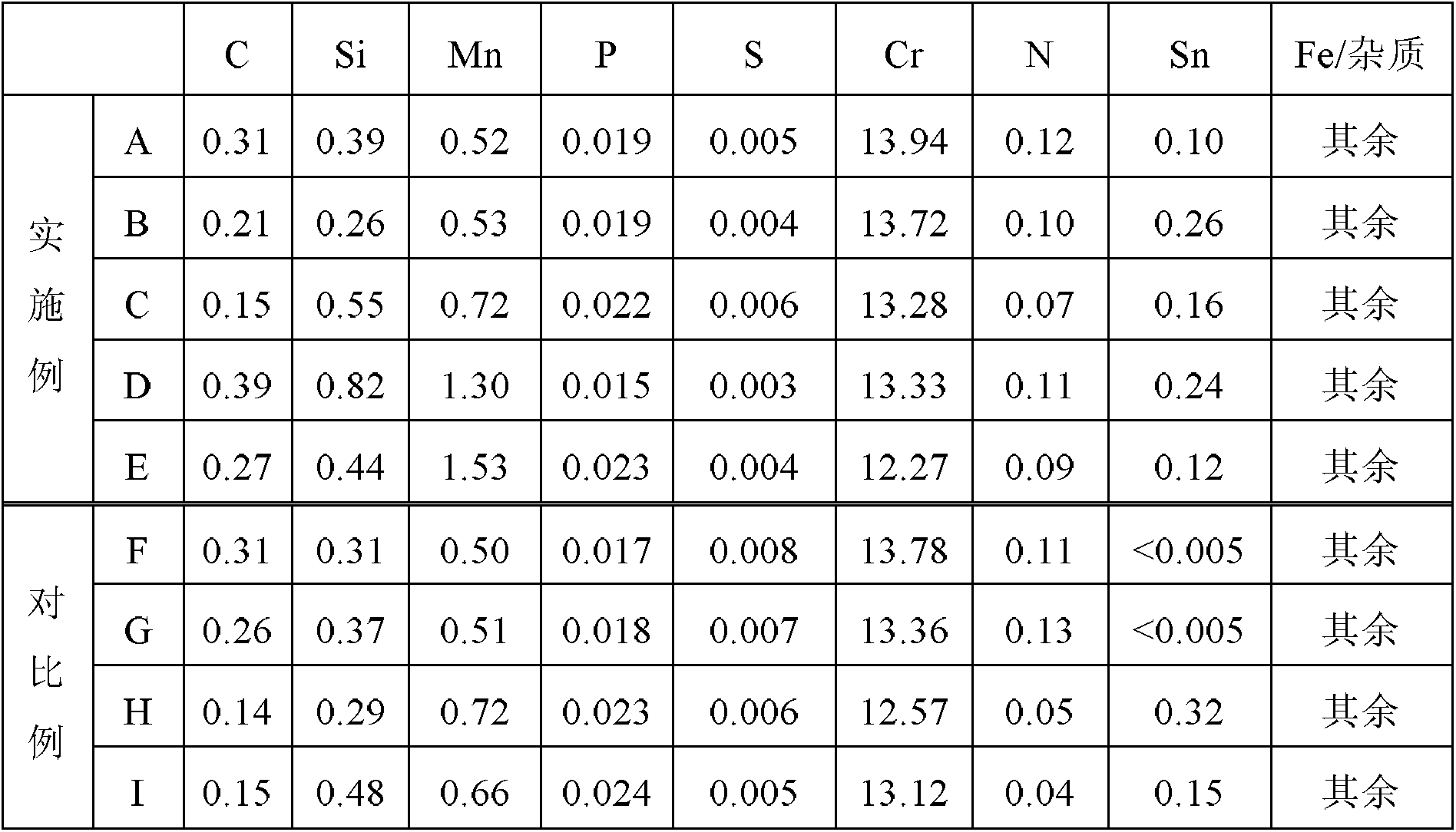

[0032] Table 2 shows the weight percentages of the chemical components of the tin-containing martensitic stainless steels of Examples A-E and the steel plates of Comparative Examples F-I below. The manufacturing method of the tin-containing martensitic stainless steel of embodiment A-E and the steel plate of comparative example F-I is: smelt according to the proportioning of chemical composition shown in table 2, after continuous casting, heating, hot rolling, annealing and heat preservation, obtain For steels A, B, C, D, E, F, G, and H shown in Table 3, the heating temperature is 1100-1250°C, the annealing temperature is 800-900°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com