Stirrer for realizing desulfurization by using mechanical stirring

A mechanical stirring and agitator technology, which is applied in the field of agitators, can solve the problems such as the decline in the service life of the agitator, and achieve the effect of alleviating the short service life, delaying the damage process, and improving economic direct sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

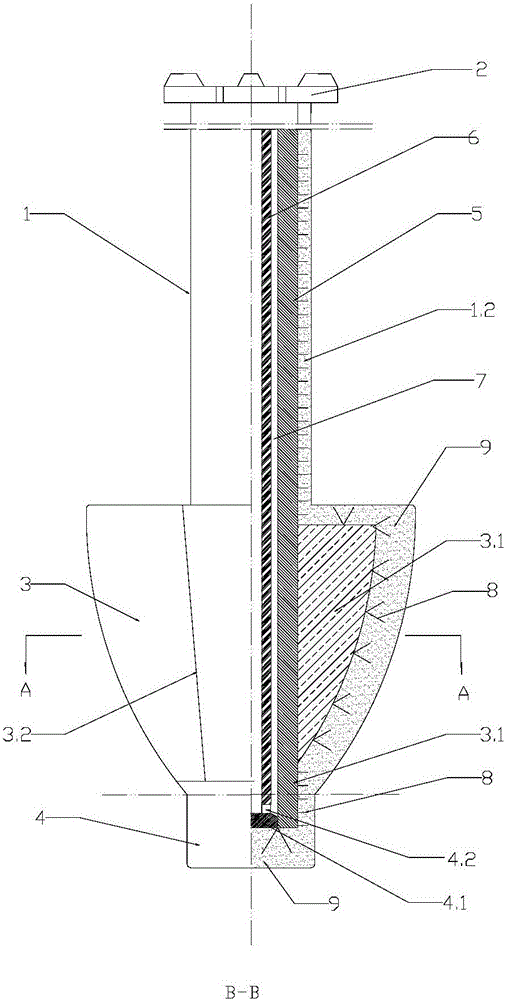

[0025] Such as figure 1 , 4 Shown in ~6: a stirrer for mechanical stirring desulfurization, which includes a stirring shaft 1 and a connecting flange 2 arranged above the stirring shaft 1, the lower end of the stirring shaft 1 is sequentially provided with 2 to 4 stirring blades 3 and The stabilizer 4, the current stabilizer 4 is a rotating body structure, the diameter of the current stabilizer 4 is constant downward along the axial direction of the current stabilizer, and the bottom of the current stabilizer 4 is a planar structure.

[0026] The inner layer of the stirring shaft 1, the stirring blade 3 and the stabilizer 4 is a hollow metal tube core 5, the top of the hollow metal tube core 5 is connected with the connecting flange 2, and a metal plug 4.1 is welded on the inner wall of the lower end of the hollow metal tube core 5, The hollow metal tube core 5 is inserted with an air-cooled pipe 6, the top of the air-cooled pipe 6 is connected to the connecting flange 2, the...

Embodiment 2

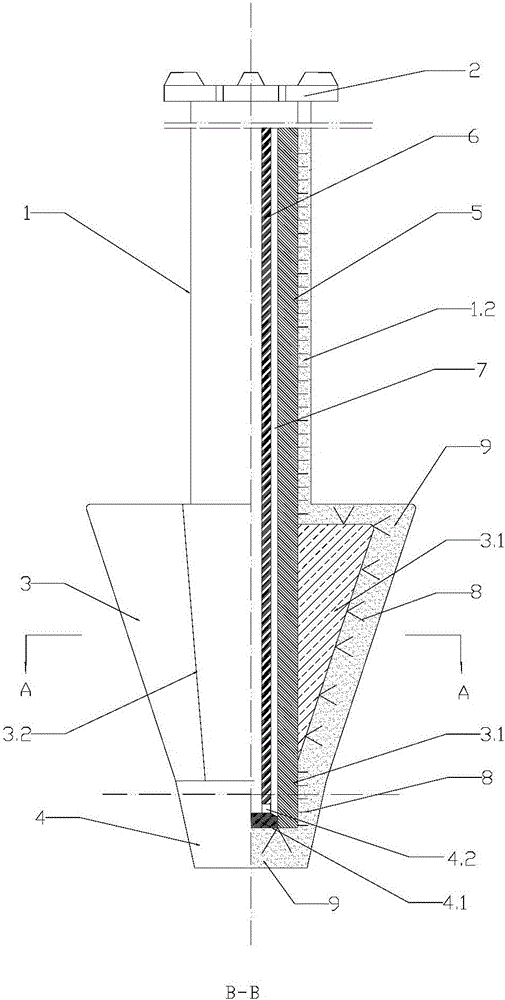

[0032] Such as figure 2 , 4 Shown in ~ 6: the structure of the agitator of this embodiment and embodiment 1 is basically the same, the difference is:

[0033] The diameter of the flow stabilizer 4 gradually decreases downward along the axial direction of the flow stabilizer, and the bottom of the flow stabilizer is a plane; the outer surface of the refractory working lining 9 at the stirring blade is an inclined surface. The outer surface of the metal core 3.1 of the stirring blade is a corresponding slope.

Embodiment 3

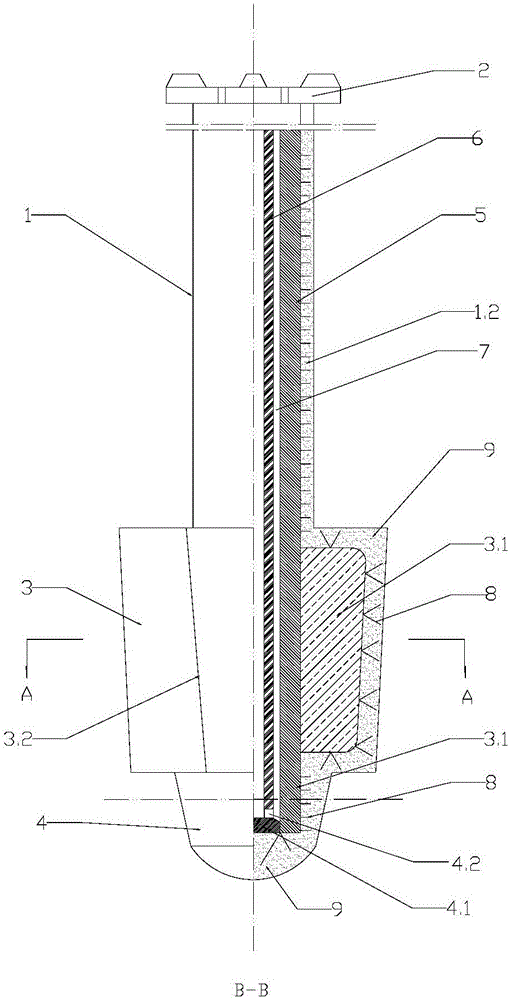

[0035] Such as Figure 3-6 Shown: the structure of this embodiment and embodiment 1 agitator is basically the same, and difference is:

[0036] The diameter of the flow stabilizer 4 decreases gradually downward along the axial direction of the flow stabilizer, and the bottom of the flow stabilizer 4 is a spherical crown structure.

[0037] The outer surface of the refractory lining 9 of the stirring blade 3 intersects the horizontal bottom surface of the refractory lining 9 of the stirring blade 3, and the outer surface of the metal core 3.1 of the stirring blade intersects the horizontal bottom surface of the metal core 3.1 of the stirring blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com