Stirring head for use in molten iron desulfurization

A technology of hot metal desulfurization and stirring head, which is applied in the direction of improving process efficiency, etc., can solve the problems of lack of heat exchange structure, accumulation of sulfur slag, impact on working life of stirring head, etc., to ensure cooling effect, prolong service life and slow down the damage process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

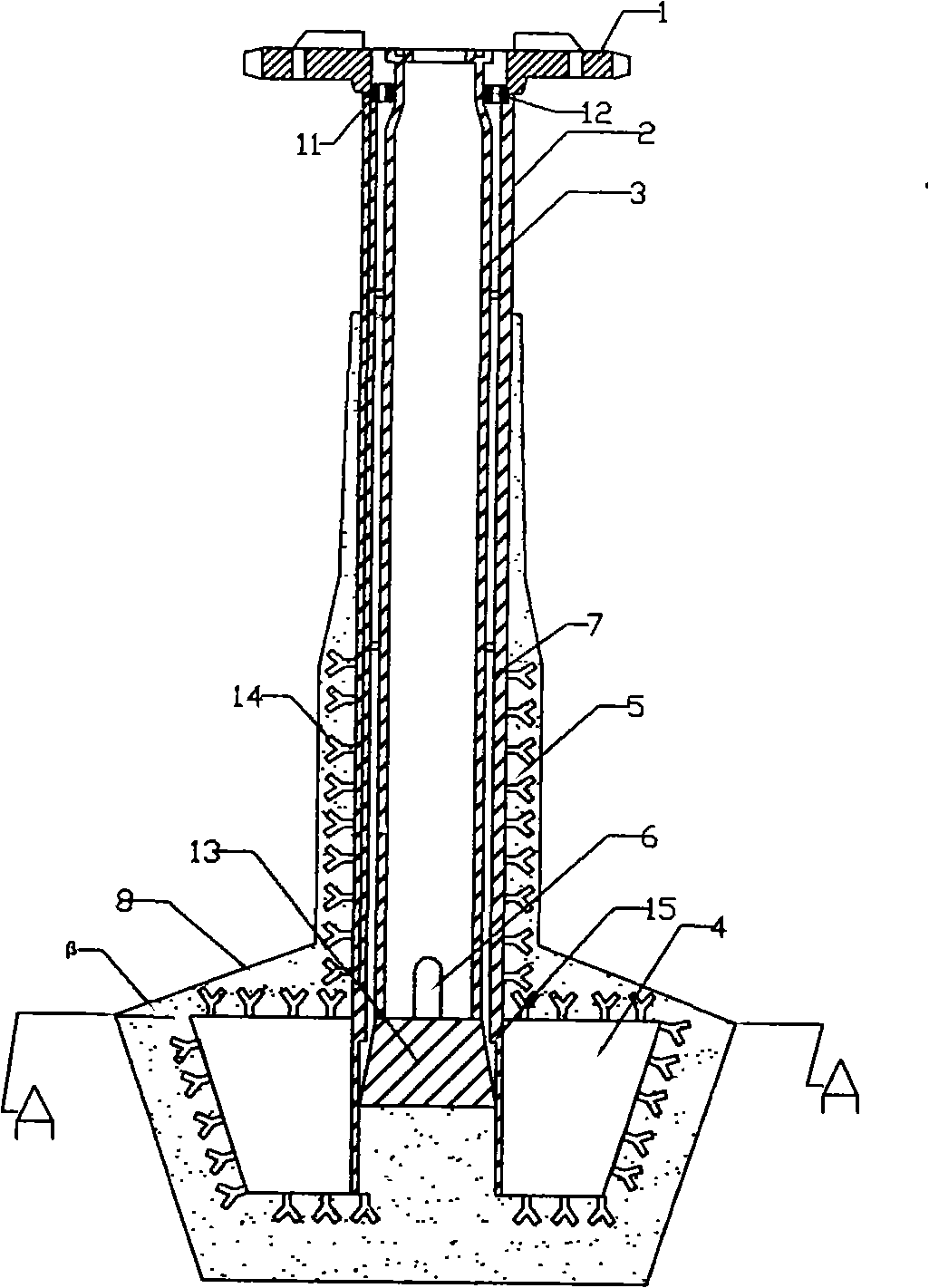

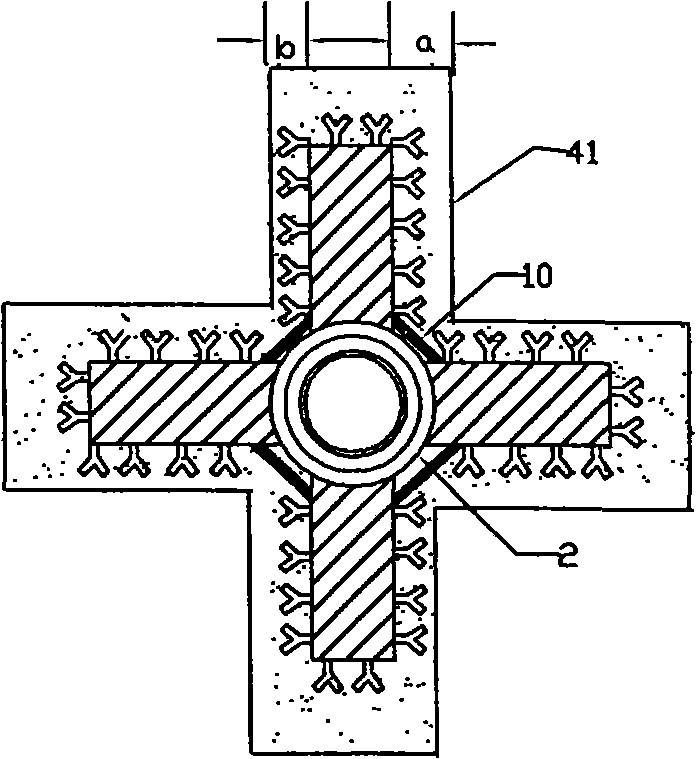

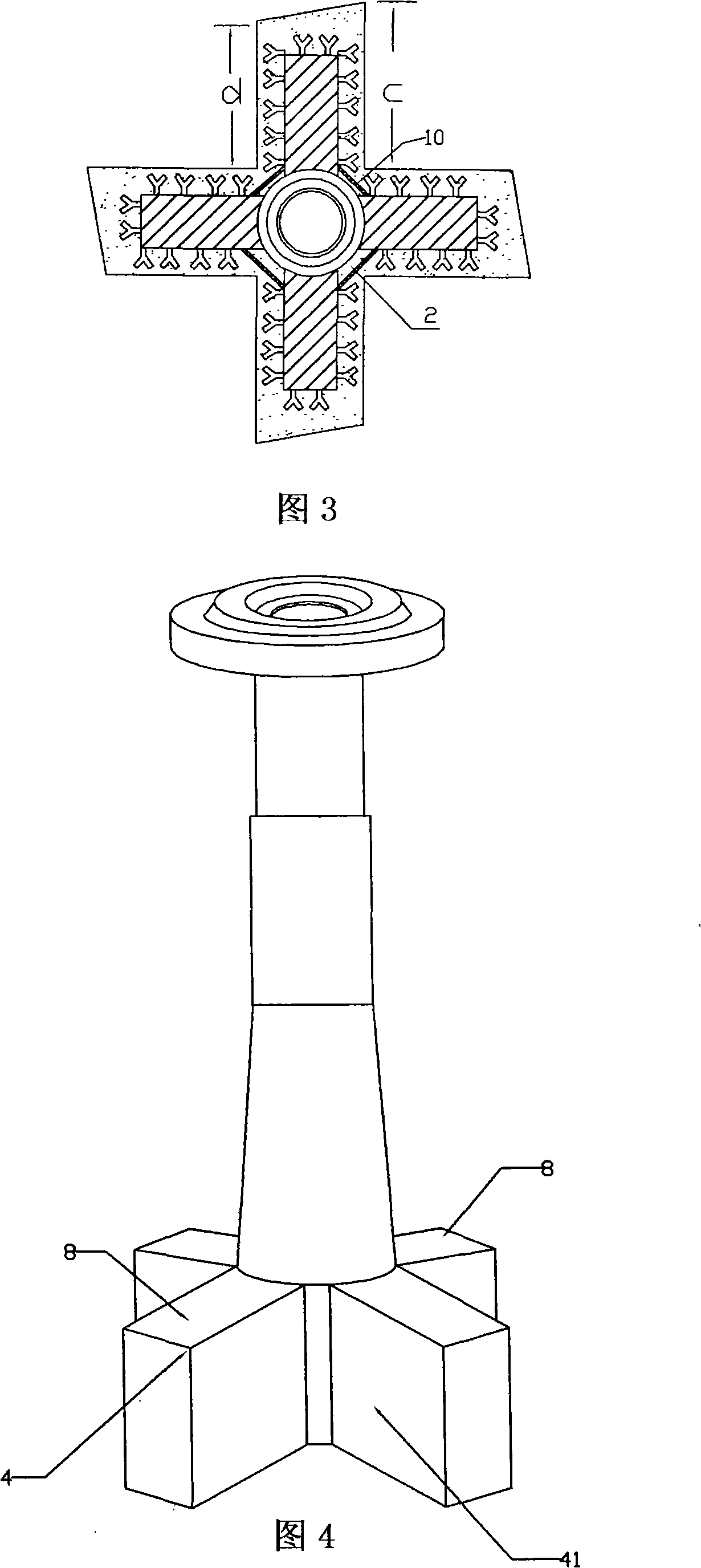

[0020] Such as figure 1 , shown in 4, a molten iron desulfurization stirring head, including a flange connection 1, a stirring shaft 2 fixedly connected with the flange connection 1, an inner tube 3 fitted in the stirring shaft 2, and a stirring shaft 2 Stirring blade 4 fixed at the bottom, refractory material layer 5 on the stirring shaft 2 and stirring blade 4; the bottom of the inner tube 3 is provided with a through hole 6; the inner cavity of the inner tube 3 is connected with the through hole 6 The inner wall of the stirring shaft 2 communicates with the columnar cavity 7 formed by the inner tube 3 . In the present invention, a skeleton 14 is fixedly arranged on the stirring blade 4 and the stirring shaft 2 . The skeleton 14 is covered by a refractory layer 5 . Such as figure 2 As shown, the cross section of the stirring blade 4 in the present invention is in the shape of a "ten". In order to prolong the service life of the present invention, the thickness a of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com