Continuous mixing reaction device

A reaction device and reaction chamber technology, applied in the direction of mixers, mixers with rotating stirring devices, chemical/physical/physicochemical fixed reactors, etc., can solve the problems of discontinuous production, unstable product quality, increased Problems such as initial investment, to achieve the effects of small footprint, shortened process time, and small initial investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

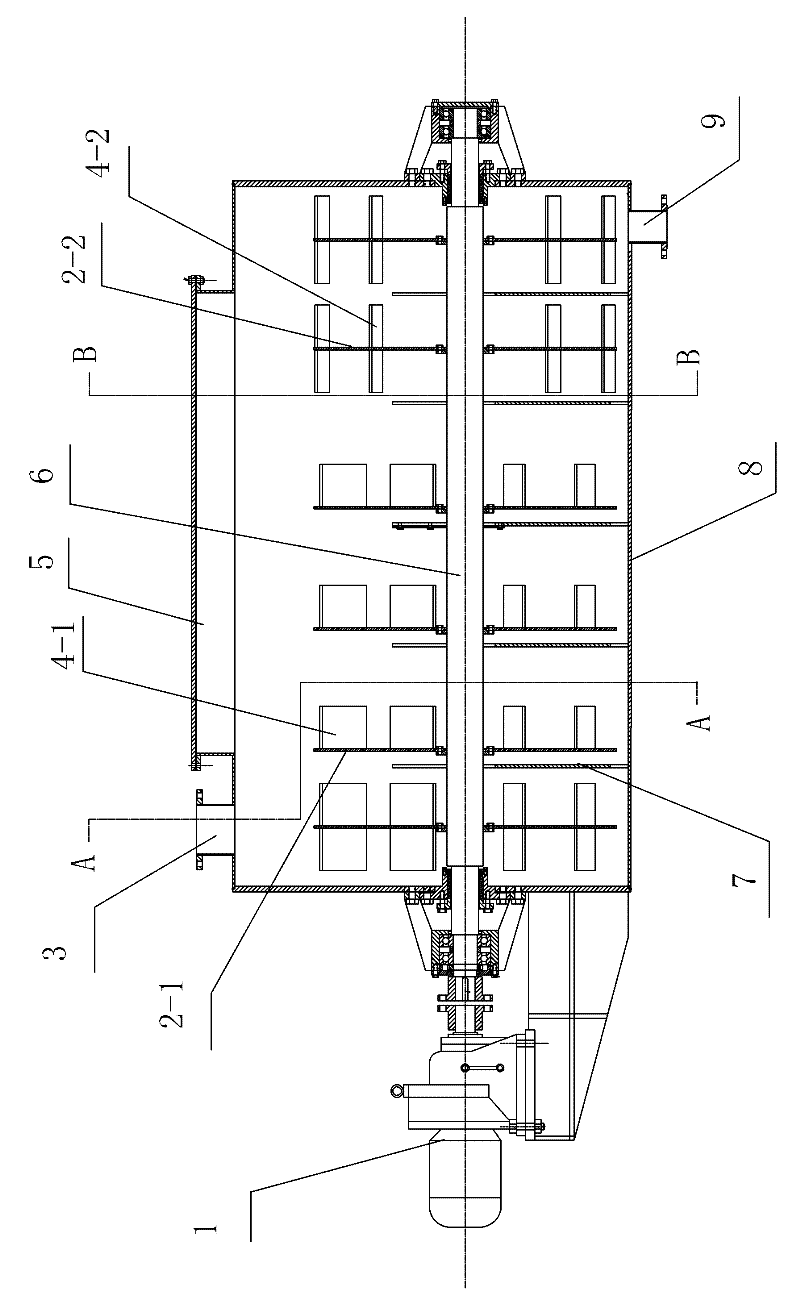

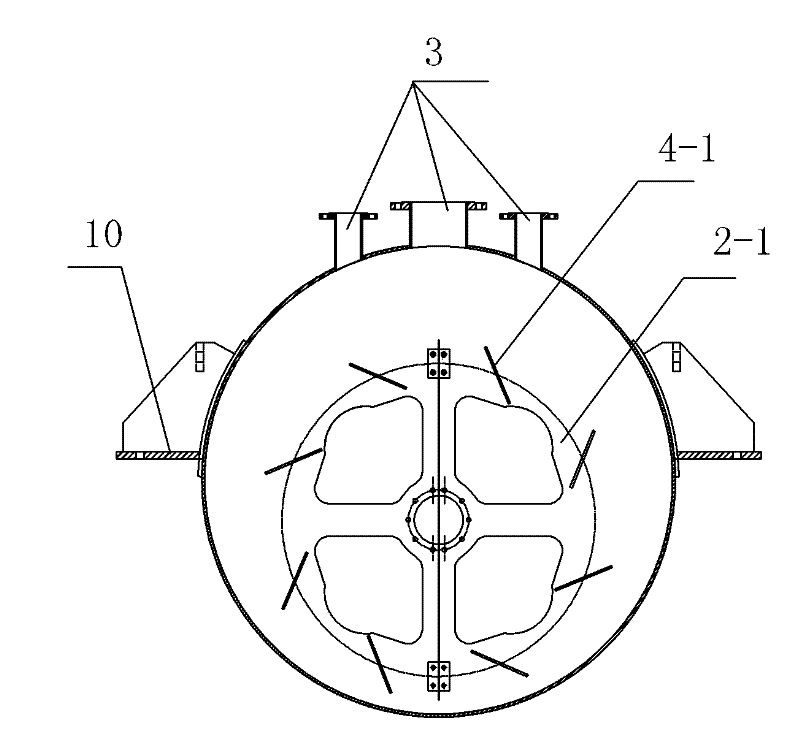

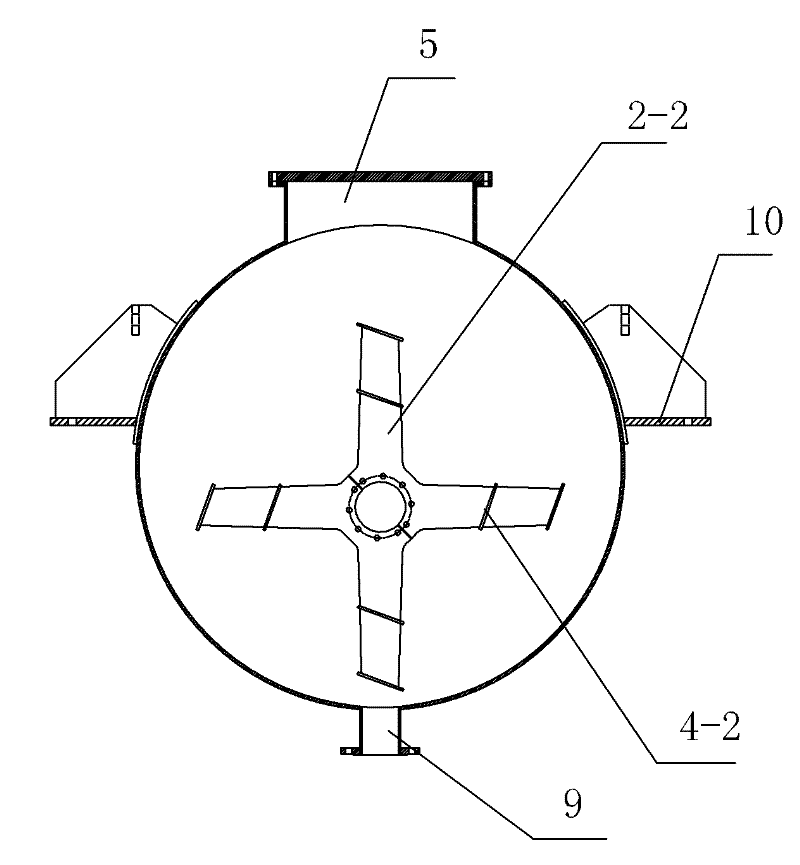

[0018] The schematic diagram of the continuous mixing reaction device of the present invention is as Figure 1-Figure 3 As shown, it includes a kettle body 8, which is provided with a manhole 5, a plurality of feed ports 3 and a discharge port 9, and the inside of the kettle body 8 is equipped with a horizontal hollow stirring shaft 6, and the horizontal type The hollow stirring shaft 6 passes through the kettle body and is connected with the stirring motor 1 through a transmission mechanism. In order to ensure the sealing performance of the kettle body, the horizontal hollow stirring shaft 6 and the kettle body 8 are rotatably sealed and connected. The interior of the kettle body 8 is divided into multiple mixing reaction chambers by a plurality of partitions 7, and a material channel is formed between the top of each partition and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com