Fast smelting method of blast furnace in-service converter

A smelting method and converter technology, applied in the field of smelting, can solve the problems of being unsuitable for the production and use of blast furnace age converters, intensified erosion of converter linings, and high content of iron oxide in slag, so as to improve the production efficiency of converters, realize scale benefits, and reduce carbon content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

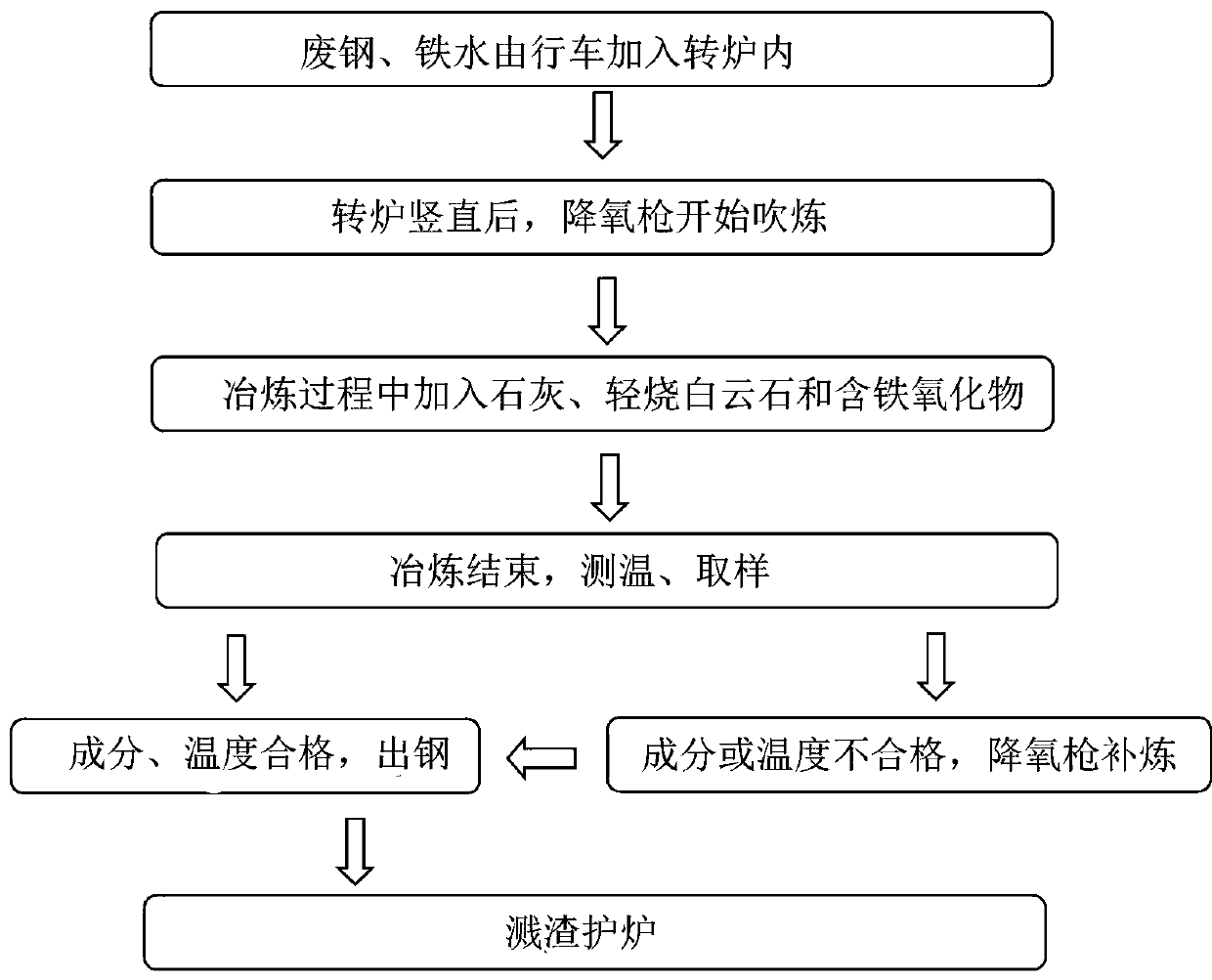

Image

Examples

Embodiment 1

[0068] Example 1: Hot metal temperature 1400°C, hot metal silicon 0.50%

[0069] The amount of steel scrap added is 30 tons, and the amount of molten iron added is 110 tons;

[0070] No slag dumping after slag splashing in the converter, scrap steel and molten iron are added to the converter, and the oxygen lance is used to blow oxygen for smelting;

[0071] After placing the oxygen lance in the converter, quickly add 1500kg of quicklime and 1200kg of lightly burned dolomite into the converter;

[0072] The position of the oxygen lance is 800-900mm. After the carbon-oxygen reaction starts, the position of the smelting lance is raised to 1200mm-1500mm, and 2500kg of quicklime is added in batches, and the addition is completed 8 minutes before smelting;

[0073] The temperature rises rapidly during the smelting process, and the iron-containing oxides are added in batches to cool down, and the addition is completed 10 minutes before the smelting.

[0074] After 10 minutes of sm...

Embodiment 2

[0077] Embodiment 2: molten iron temperature 1320°C, molten iron silicon 0.30%

[0078] 1) The amount of steel scrap added is 30 tons, and the amount of molten iron added is 113 tons;

[0079] 2) Pour out half of the slag after splashing the slag in the converter, add scrap steel and molten iron into the converter, and then put down the oxygen lance to blow oxygen for smelting;

[0080] 3) After the oxygen lance is lowered in the converter, quickly add 1200kg of quicklime weighed in advance and 1200kg of lightly burned dolomite into the converter;

[0081] 4) The position of the oxygen lance is 800-900mm. After the carbon-oxygen reaction starts, the position of the smelting lance is raised to 1200mm-1500mm, and 2000kg of quicklime is added in batches, and the addition is completed 8 minutes before smelting;

[0082] 5) After 10 minutes of smelting, start to lower the oxygen lance step by step, and the oxygen lance will be lowered to 600-700mm in 11 minutes and 30 seconds, and...

Embodiment 3

[0085] Embodiment three: molten iron temperature 1280 ℃, molten iron silicon 0.25%

[0086] 1) The amount of steel scrap added is 26 tons, and the amount of molten iron added is 115 tons;

[0087] 2) Pour out all the slag splashing in front of the converter, put scrap steel and molten iron into the converter, and put oxygen lance into it for oxygen blowing smelting;

[0088] 3) After placing the oxygen lance in the converter, quickly add 1000kg of quicklime and 800kg of lightly burned dolomite into the converter;

[0089] 4) The position of the oxygen lance is 800-900mm. After the carbon-oxygen reaction starts, the smelting lance position is raised to 1200mm-1500mm, and 2000kg of quicklime and 400kg of lightly burned dolomite are added in batches, and the addition is completed 8 minutes before smelting;

[0090] 5) After 10 minutes of smelting, start to lower the oxygen lance step by step, and the oxygen lance will be lowered to 600-700mm in 11 minutes and 30 seconds, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com