Multifunctional stirring machine

A mixer and multi-functional technology, applied in the direction of mixer accessories, mixers, mixers with rotating containers, etc., can solve the problems of difficult operation and control, low mixing uniformity, and easy generation of broken particles, etc., to improve equipment work Quality, improve equipment efficiency, increase the effect of stirring intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

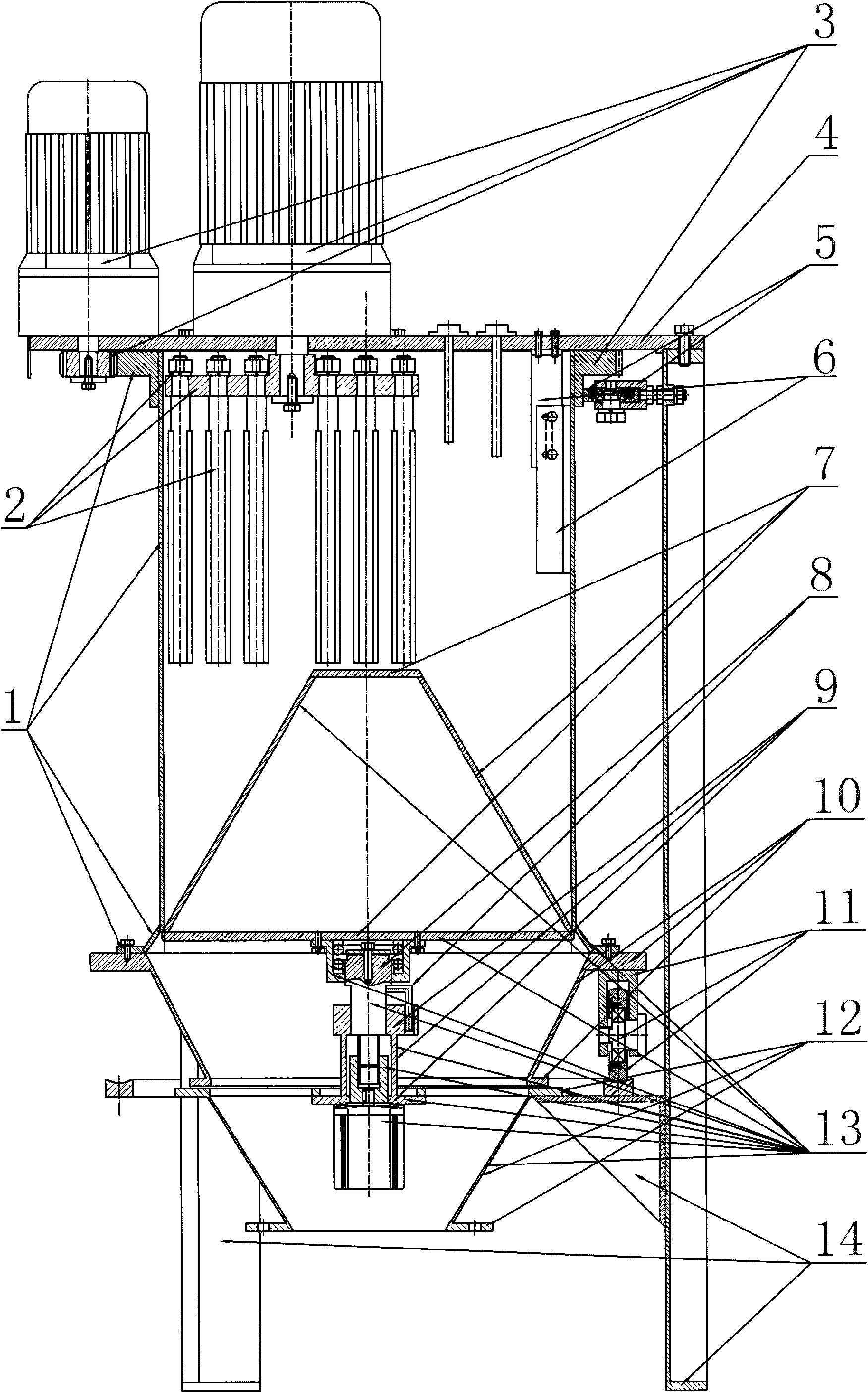

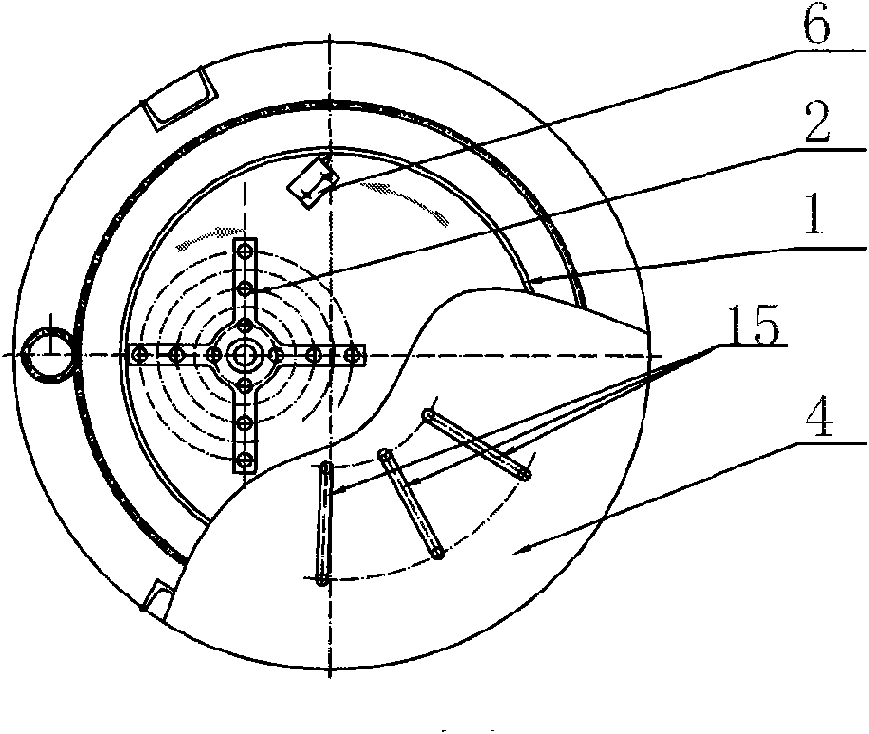

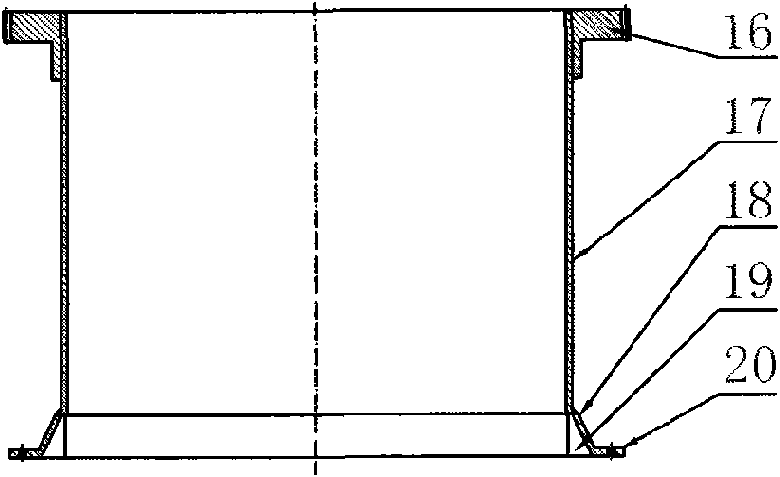

[0054] Such as figure 1 Shown: the present invention is made up of barrel weldment 1, agitator part 2, transmission mechanism 3, cover plate 4, top wheel part 5, scraper part 6, conical cylinder bottom weldment 7, support shaft weldment 8, support Shaft seat welding part 9, material receiving cone welding part 10, roller part 11, discharge cone welding part 12, electrical material level automatic control device 13 and frame welding part 14 are composed. Such as figure 2 Shown: the axis of rotation of the agitator part 2 of the present invention and the axis of rotation of the container assembly 74 have a specific eccentricity, and the direction of rotation of the agitator part 2 is opposite to the direction of rotation of the container assembly 74. The elongated feeding port 15 that is identical with the number of kinds of materials participating in the mixing is set on the top. Such as image 3 Shown: the main body of the material cylinder weldment 1 of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com