Plant mixing device and method for continuous vibratory stir processing of stabilized soil

A technology of vibration mixing and processing methods, which is applied in mixing plants, clay preparation equipment, cement mixing equipment, etc., and can solve problems such as poor reliability of the whole machine, poor stiffness of the stirring shaft, and improvement of the quality of the mixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

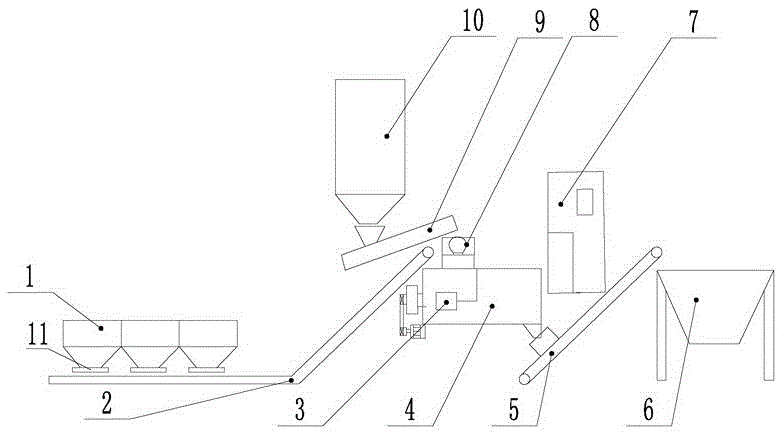

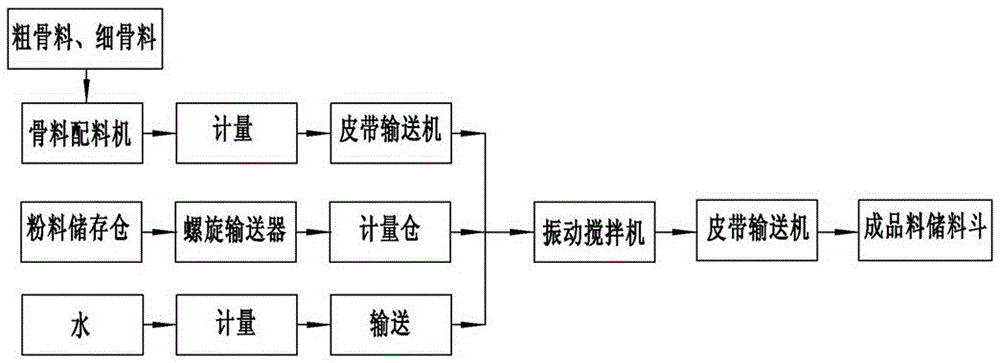

[0029] Such as figure 1 with figure 2 Shown, a kind of stabilized soil continuous vibrating stirring processing factory mixing equipment, comprises continuous feeding device, continuous weighing device, continuous vibrating stirring device, continuous discharging device, water supply system 3 and electric control system 7, described water supply System 3 includes a water tank, a flow meter and a water pump. The electrical control system controls a continuous feeding device, a continuous weighing device, a continuous vibrating stirring device and a continuous discharging device. The continuous feeding device includes an aggregate batching machine 1 and an aggregate The belt conveyor 2 downstream of the batching machine 1 and the powder storage bin 10 and the screw conveyor 9 downstream of the powder storage bin 10, the aggregate batching machine 1 includes a batching bin and a weighing belt conveyor 11, and the end of the weighing belt conveyor 11 A belt conveyor 2 is provide...

Embodiment 2

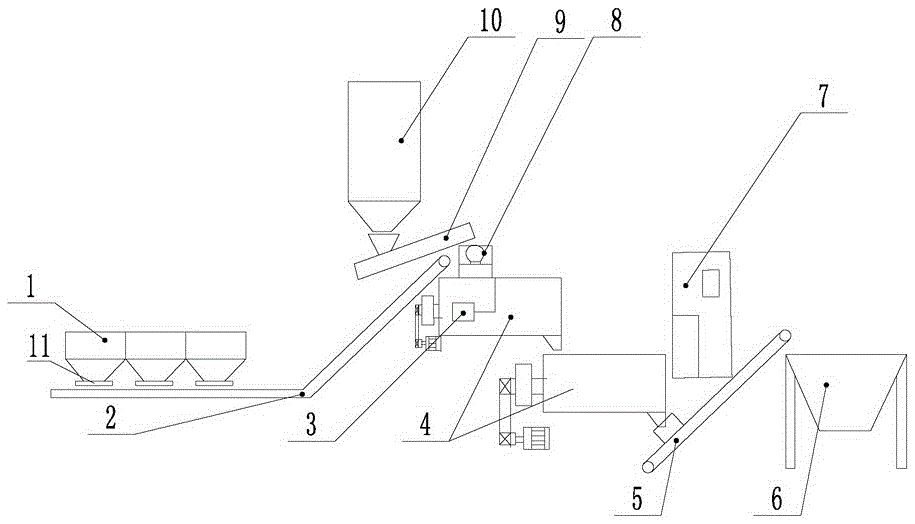

[0035] Such as image 3 with Figure 4Shown, a kind of stabilized soil continuous vibrating stirring processing factory mixing equipment, comprises continuous feeding device, continuous weighing device, continuous vibrating stirring device, continuous discharging device, water supply system 3 and electric control system 7, described water supply System 3 includes a water tank, a flow meter and a water pump. The electrical control system controls a continuous feeding device, a continuous weighing device, a continuous vibrating stirring device and a continuous discharging device. The continuous feeding device includes a continuously graded aggregate batching machine 1 and the belt conveyor 2 downstream of the aggregate batching machine 1 and the powder storage bin 10 and the screw conveyor 9 downstream of the powder storage bin 10, the aggregate batching machine 1 includes a batching bin and a weighing belt conveyor 11, and the weighing belt The end of the machine 11 is provide...

Embodiment 3

[0041] Such as Figure 5 with Image 6 Shown, a kind of stabilized soil continuous vibrating stirring processing factory mixing equipment, comprises continuous feeding device, continuous weighing device, continuous vibrating stirring device, continuous discharging device, water supply system 3 and electric control system 7, described water supply System 3 includes a water tank, a flow meter and a water pump. The electrical control system controls a continuous feeding device, a continuous weighing device, a continuous vibrating stirring device and a continuous discharging device. The continuous feeding device includes a continuously graded aggregate batching machine 1 and the belt conveyor 2 downstream of the aggregate batching machine 1 and the powder storage bin 10 and the screw conveyor 9 downstream of the powder storage bin 10, the aggregate batching machine 1 includes a batching bin and a weighing belt conveyor 11, and the weighing belt The end of the machine 11 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com