Bottom spraying type limestone smelting method of combined top-bottom combined blowing converter

A technology of top-bottom re-blowing and smelting method, applied in the field of metallurgy, can solve the problems of lime powder without a specific solution, not environmentally friendly, time-consuming and energy-consuming, etc., to improve slag-making smelting efficiency, shorten the mixing time of components, and improve dephosphorization. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

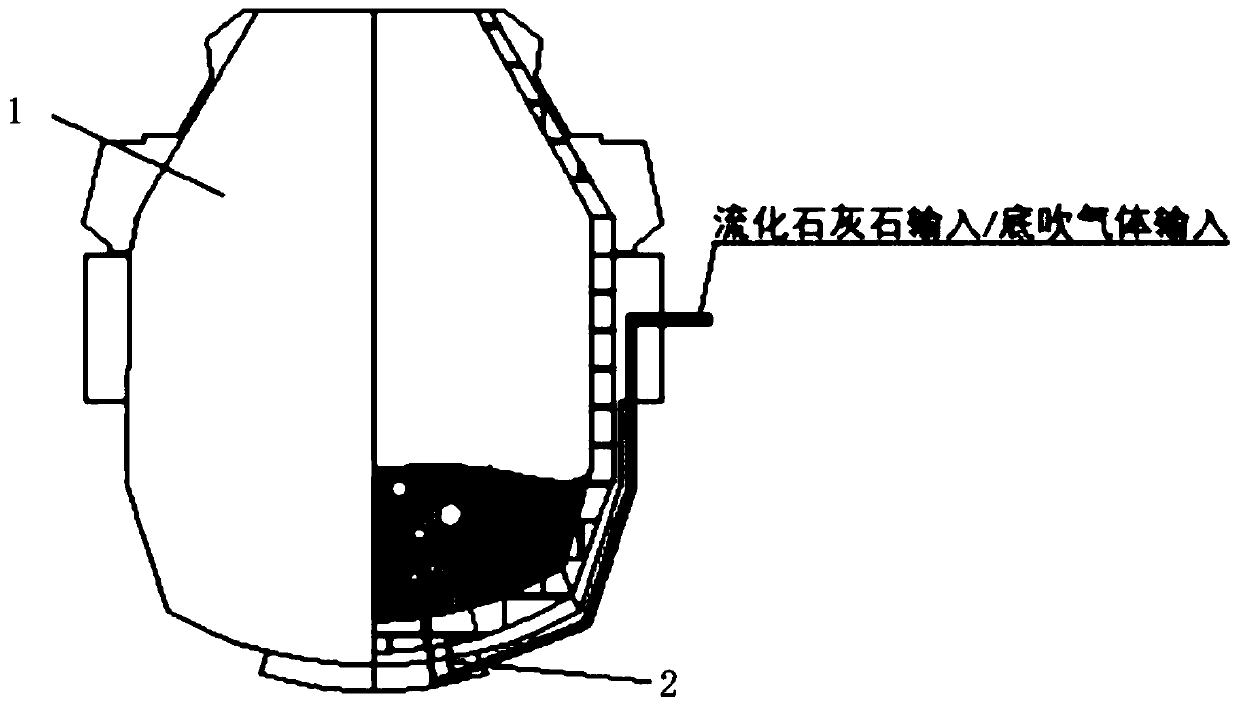

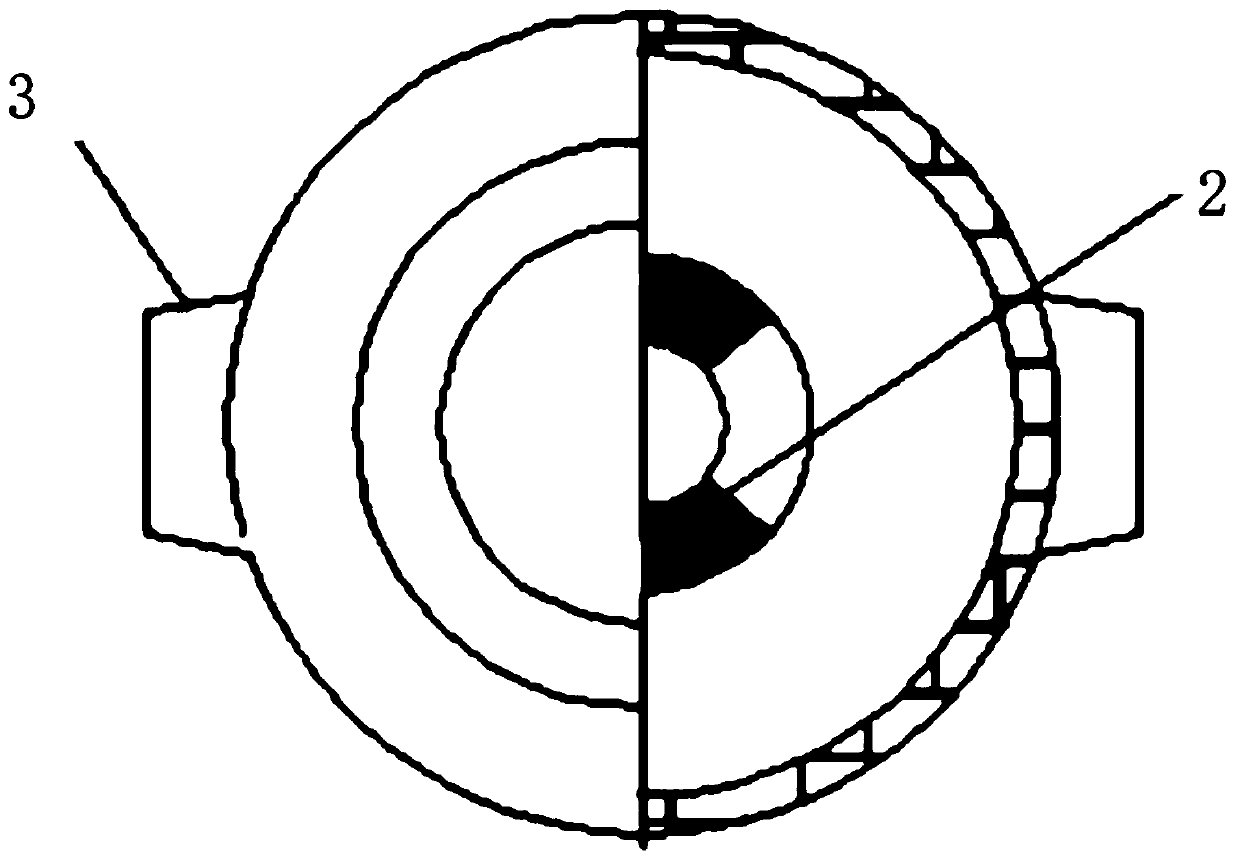

[0031] For different types of top-bottom combined blowing converters (100t, 150t, 210t, 300t), the central line of the converter is used as the axis, and the special ventilation blowing element 2 is arranged in a ring shape at the bottom of the furnace. According to the size of the converter, it can be divided into 4, 6, and , 8 pieces (can be flexibly adjusted according to the size of the furnace molten pool) are evenly arranged on the concentric circle of the furnace bottom. Add molten iron into the converter, shake the furnace body, lower the top blowing mechanism to blow oxygen, add the first batch of slagging material, and start the bottom blowing of the converter gas at the same time; choose the best to use the switching valve to switch the timing, injection time, Carrier gas supply pressure, gas supply intensity and the amount of limestone carried, stop oxygen blowing, and organize tapping.

Embodiment 2

[0033]The top-bottom combined blowing converter furnace type (100t, 150t, 210t, 300t) involved in this embodiment adopts the axis along the center line of the converter, and the layout and quantity of the special ventilating blowing elements 2 at the bottom of the furnace are the same as in Embodiment 1, the difference is that The distribution of the special ventilating blowing elements 2 on the concentric circles of the furnace bottom is asymmetrical. Add molten iron into the converter, shake the furnace body 1, lower the top blowing mechanism to blow oxygen, add the first batch of slagging material, and start the bottom blowing of the converter gas at the same time; determine the optimal timing and injection time by using the switching valve after 2 minutes of top blowing , Carrier gas supply pressure, gas supply intensity and the amount of limestone carried, stop oxygen blowing, and organize tapping.

[0034] It can be seen from Example 1 and Example 2 that the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com