Device and method for improving jet flow impact effect by utilizing injecting powder in electric arc furnace steelmaking

An electric arc furnace, powder technology, applied in electric furnace, process efficiency improvement, furnace and other directions, can solve the problems of low powder yield, low powder particle moving speed, fast oxygen jet decay speed, etc., to improve the penetration depth, The effect of strengthening the stirring intensity and improving the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

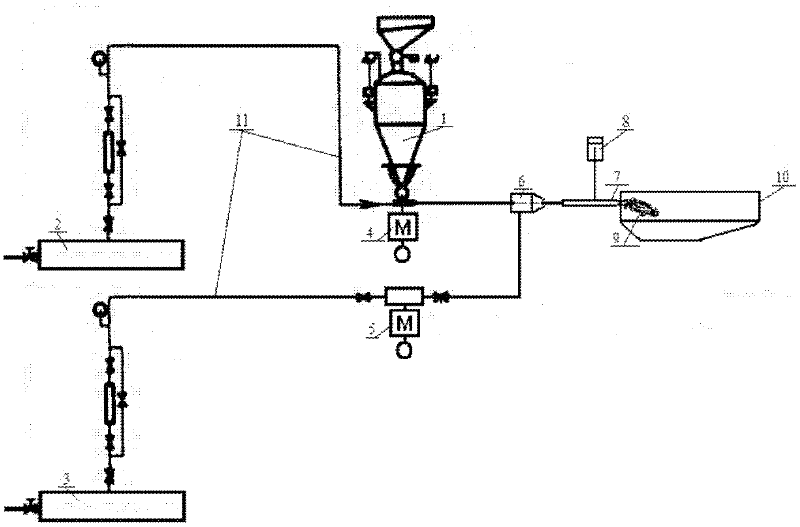

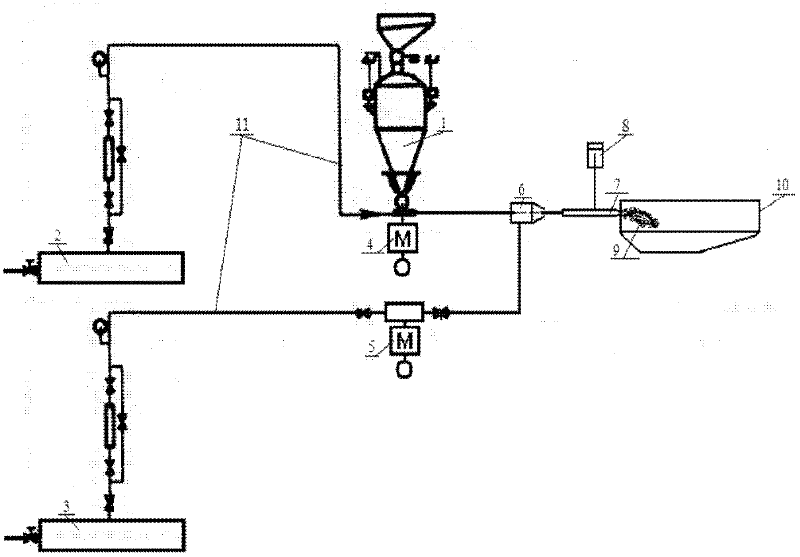

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

[0026] Embodiment 1.60 ton electric arc furnace

[0027] The invention is applied to a 60t ultra-high power electric arc furnace. The powder control system controls the delivery carrier gas flow rate to 180Nm 3 / h, the powder flow rate is 12kg / min; the oxygen control system controls the oxygen flow rate to 1200Nm 3 / h; powder and oxygen respectively enter the gas-solid phase mixer along the conveying pipeline to form a gas-solid mixed phase with a flow rate of 1380Nm 3 / h, the pressure is 1.1Mpa;

[0028] The gas-solid mixed phase enters the supersonic generator along the conveying pipeline to generate a high-speed mixed jet with a jet velocity of 470m / s; under the protection of the water cooling protection device, the high-speed mixed jet enters the electric arc furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com