Preparation method of high-quality Al-Ti-B-Sr master alloy composite refining modifier

A technology of al-ti-b-sr, refining modifier, used in materials and metallurgy, preparation of high-quality Al-Ti-B-Sr master alloy composite refining modifier, high-quality Al-Ti-B- In the field of Sr master alloy composite refining modifier, it can solve the problems of high reaction temperature, high metal Sr activity, affecting refining and modification effects, etc., and achieve the effect of high refining performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

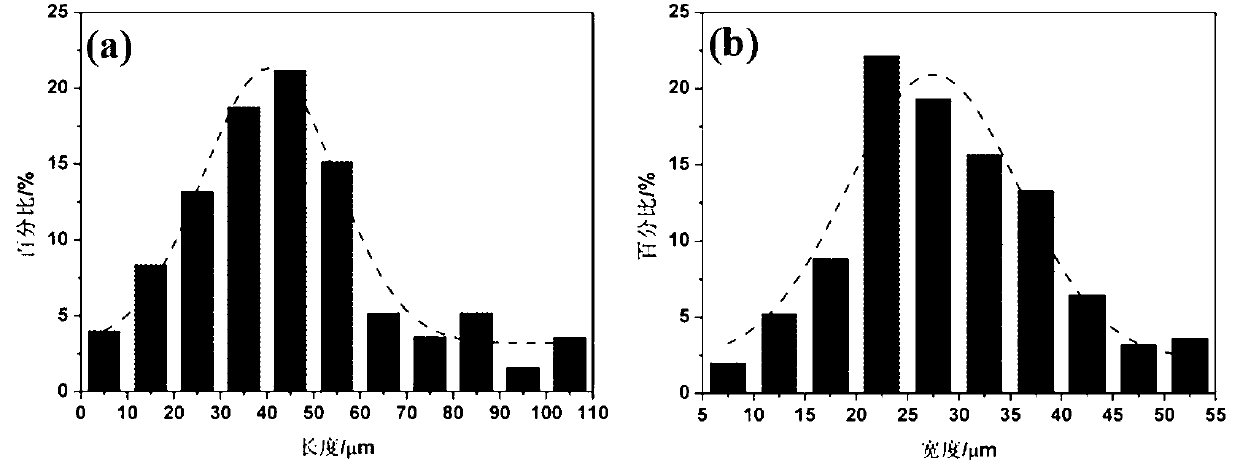

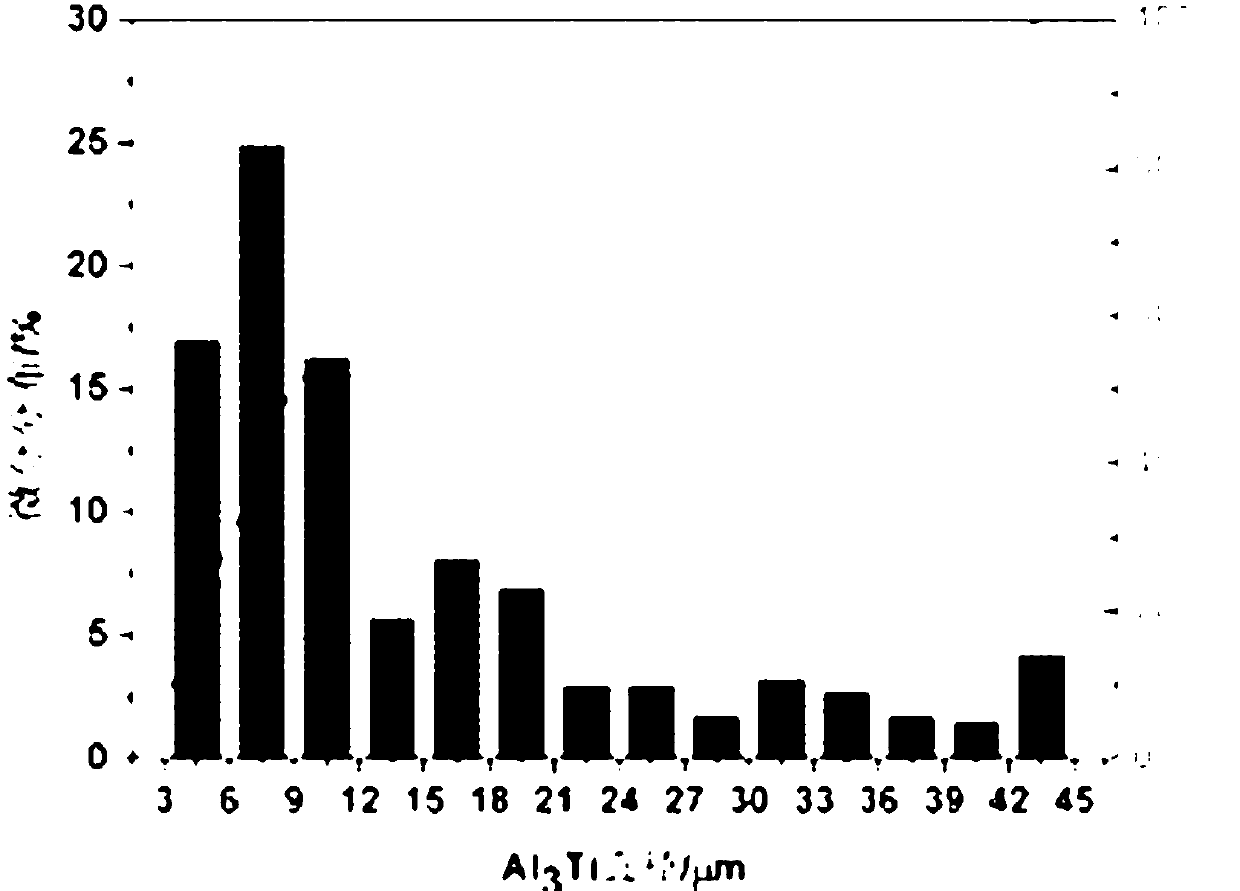

[0047] Embodiment 1: the manufacture of high-quality Al-5Ti-1B-10Sr master alloy wire rod

[0048] Melt 522kg of aluminum ingots with a purity of 99.7% in an aluminum melting furnace and heat them to 736°C, then pour them into an intermediate frequency induction furnace to remove impurities and oxide films on the surface of the molten aluminum and prepare for the alloying process. Weigh 100kg of K with a purity of 98% 2 TiF 6 and 100kg (for the required KBF 4 80% of the total) KBF with a purity of 98% 4 Ingredients, mix well. Weigh the K just now 2 TiF 6 +KBF 4 The mixture is added to the molten aluminum at a speed of 24kg / min, accompanied by strong stirring. After the first step of feeding is completed, continue to stir until the sampling and analysis components are qualified, and then weigh 161kg of K with a purity of 98% for the second time. 2 TiF 6 and 25kg of KBF with a purity of 98% 4 Mix the raw materials and add molten aluminum at a speed of 22kg / min, accompa...

Embodiment 2

[0052] Embodiment 2: the manufacture of high-quality Al-5Ti-1B-5Sr alloy wire rod

[0053] Melt 505kg of aluminum ingots with a purity of 99.7% in an aluminum melting furnace and heat them to 736°C, then pour them into an intermediate frequency induction furnace to remove impurities and oxide films on the surface of the molten aluminum and prepare for the alloying process. Weigh 65kg of K with a purity of 98% 2 TiF 6 and 65kg (for required KBF 4 80% of the total) KBF with a purity of 98% 4 Ingredients, mix well. Weigh the K just now 2 TiF 6 +KBF 4 The mixture is added to the molten aluminum at a speed of 24kg / min, accompanied by strong stirring. After the first step of feeding is completed, continue to stir until the sampling analysis composition is qualified, then weigh 104kg of K with a purity of 98% for the second time. 2 TiF 6 and 16kg of KBF with a purity of 98% 4 Mix the raw materials and add molten aluminum at a speed of 22kg / min, accompanied by strong stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com