Turntable movement and transmission mechanism of numerical control steel reinforcement cage forming machine

A steel cage forming machine and transmission mechanism technology, which is applied to the manufacture of ring nets, other household appliances, household appliances, etc., can solve the problems of large waste of materials and energy, noise and environmental pollution, and poor processing quality, and achieve The effect of saving energy consumption, reducing labor intensity and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

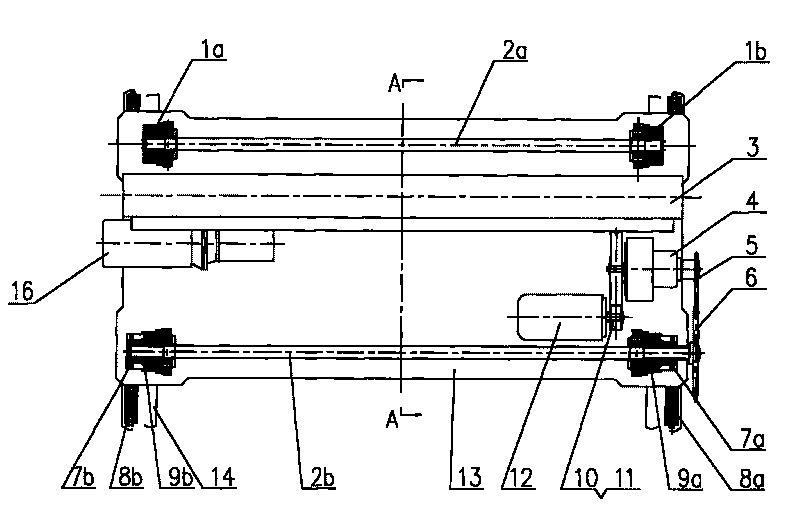

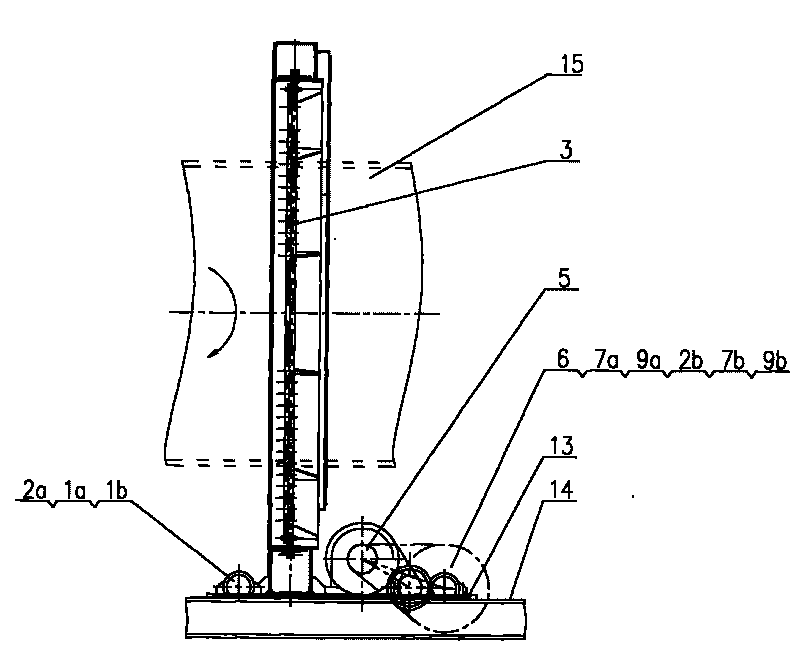

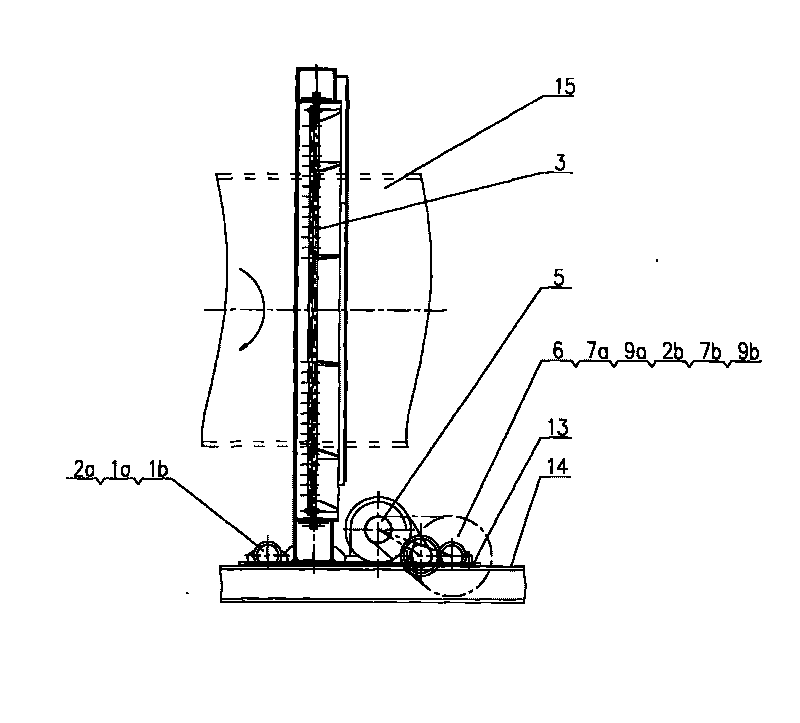

[0012] figure 1 It is a top view of the present invention; figure 2 yes figure 1 A-A sectional view in .

[0013] The present invention provides a turntable moving transmission mechanism of a numerically controlled reinforcement cage forming machine, said turntable moving transmission mechanism comprising: a frame base 14; a movable base 13 located on the frame base 14; a turntable 3 installed on the movable base; The transmission device that moves movable base 13.

[0014] The transmission device for dragging the movable base to move includes: a first chain 8a and a second chain 8b fixed on the frame base 14 with the same structure and parallel and symmetrically arranged; a transmission drive mechanism fixed on one end of the movable base 13; The driving mechanism is connected with a rotatable second shaft 2b; the first driven sprocket 7a an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com