Automatic wielding mechanical device for forming machine of numerical control reinforcing cage

A steel cage forming machine, automatic welding technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems affecting the production efficiency and quality of steel cages, labor intensity of many personnel, irregular welding point forming, etc. The effect of saving manpower, improving welding quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

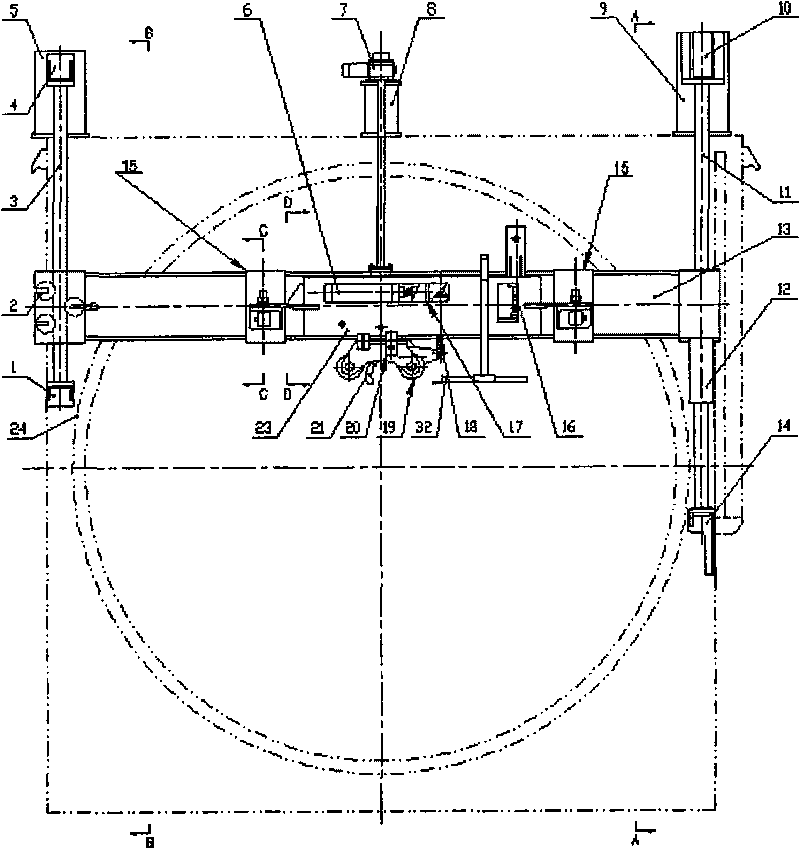

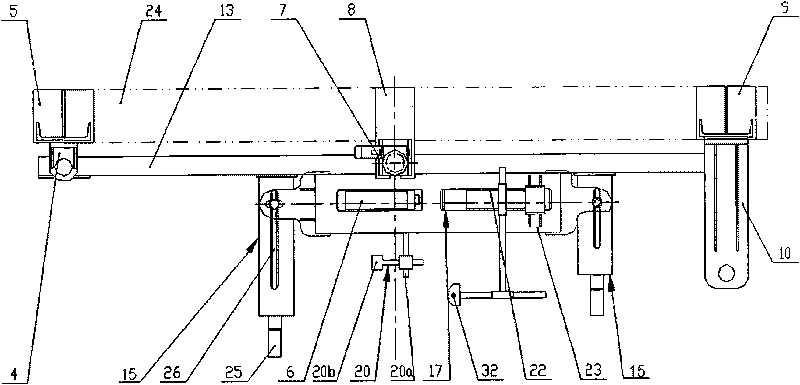

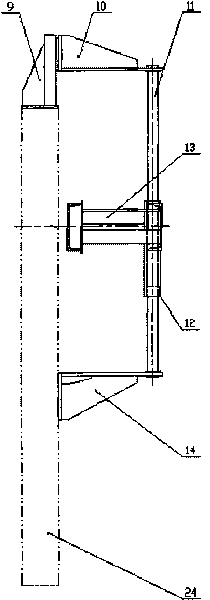

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 , figure 2 As shown, the present invention provides an automatic welding mechanical device of a numerically controlled reinforcement cage forming machine. The automatic welding mechanical device includes: a turntable frame 24; Two guide posts 11; the mobile support 13 that is arranged on one side of the turntable frame 24, the left and right sides of the mobile support 13 are slidably fitted on the first guide post 3 and the second guide post 11, and the top of the mobile support 13 is equipped with The elevator 7 that drives the mobile support 13 to move up and down; a box shell 23 is arranged on one side of the mobile support 13 .

[0025] The box shell 23 is provided with a hook 21 , a rolling mechanism 19 , a welding torch support mechanism 20 and a pitch adjusting mechanism 15 for adjusting the position and angle of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com