Equipment capable of manufacturing reinforcing cages with various section shapes

A technology of cross-sectional shape and reinforcement cage is applied in the field of equipment for manufacturing reinforcement cages with various cross-sectional shapes, which can solve the problems of low production efficiency, high labor intensity and high cost, and achieve high production efficiency, low labor intensity and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

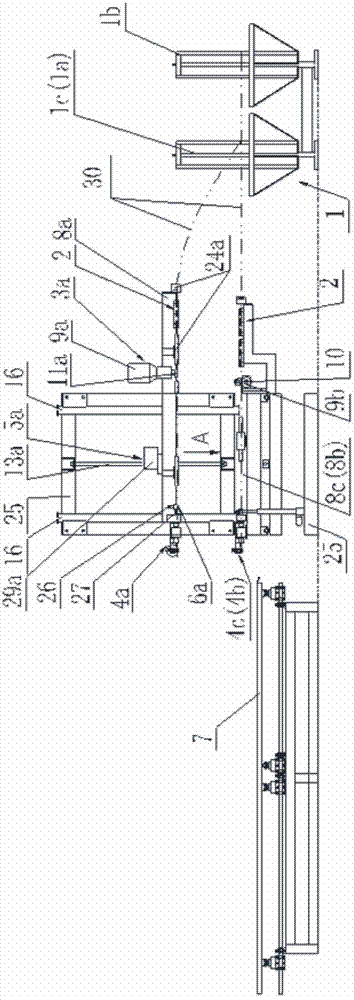

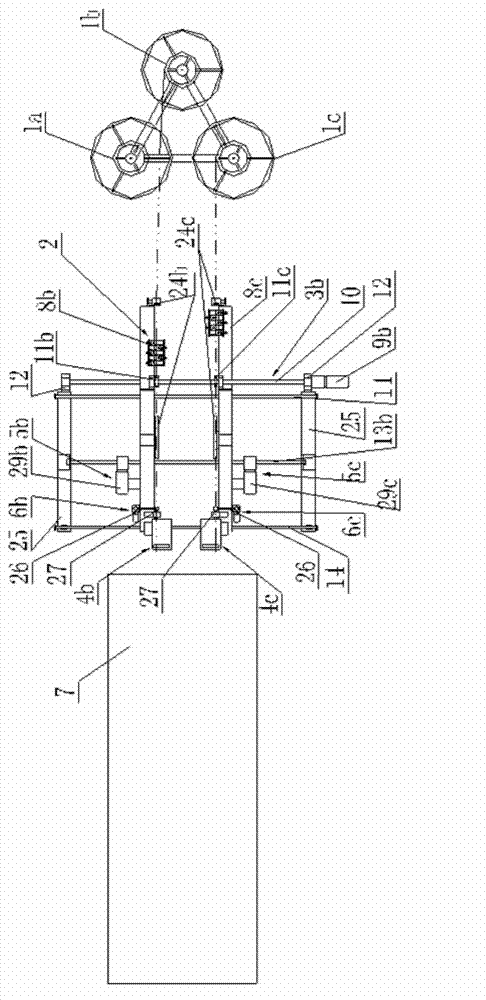

[0020] As shown in the figure, the present invention provides a kind of equipment that manufactures the reinforcement cage of various cross-section shapes, and the equipment of described manufacture multiple cross-section shapes reinforcement cage comprises: the pay-off reel 1 that main reinforcement 30 is housed; The frame 25 on the side; the frame 25 is provided with: a straightening mechanism 2, a first traction mechanism 3a, a second traction mechanism 3b, and a welding mechanism.

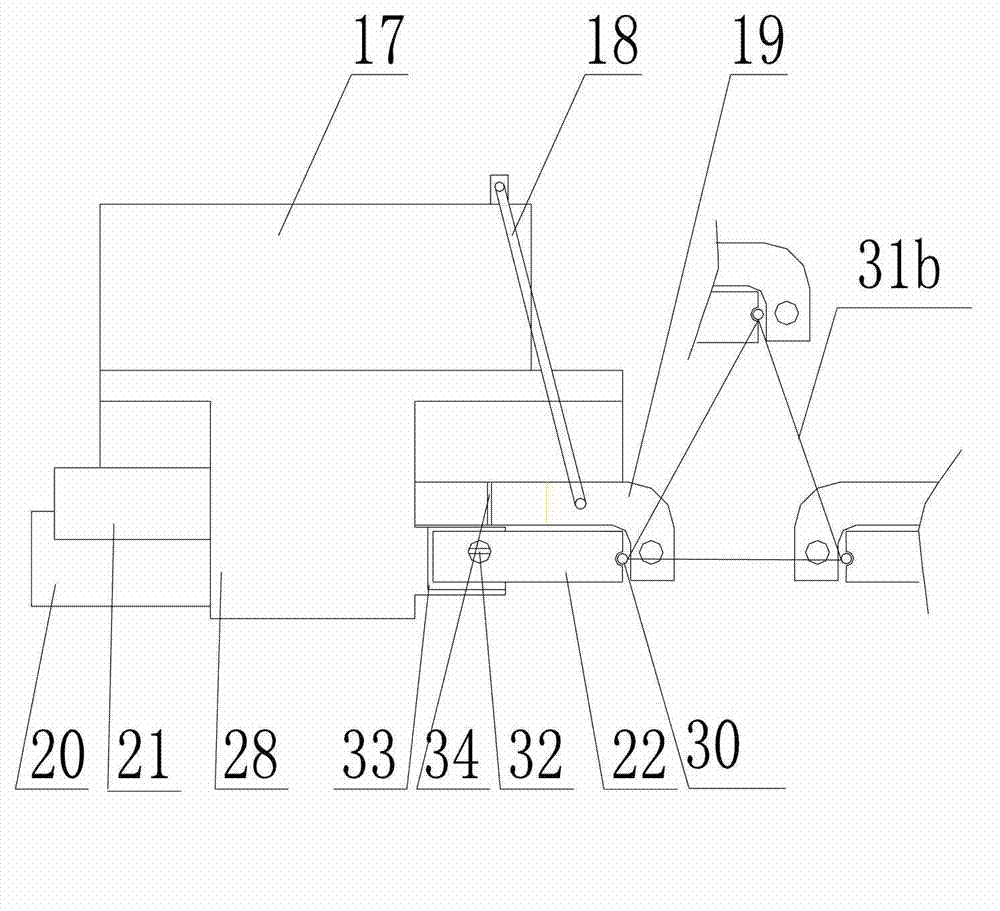

[0021] The welding mechanism includes: multiple sets of welded joints with the same structure, the multiple sets of welded joints are arranged at intervals in the cross section perpendicular to the moving direction of the main rib 30, and the multiple sets of welded joints are respectively connected to the position adjustment mechanism and the angle adjustment mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com