Half-shaft separation-type reinforcement cage making equipment and use method

A steel cage and separation technology, which is applied in the field of semi-shaft separation steel cage production equipment, can solve the problems of complicated operation, time-consuming and laborious, stirrup deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

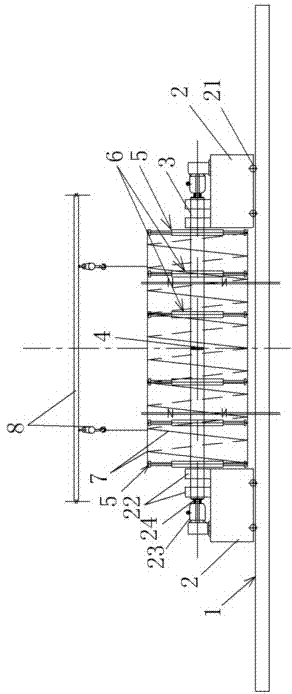

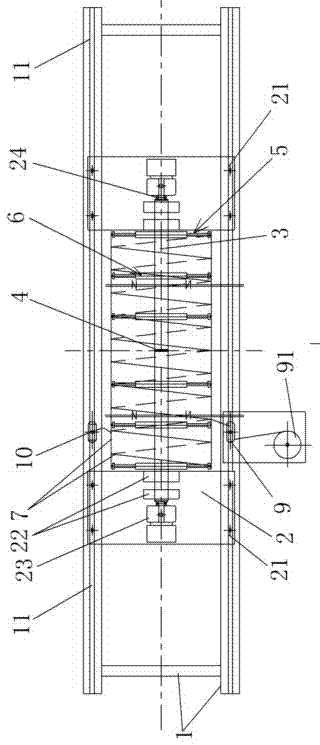

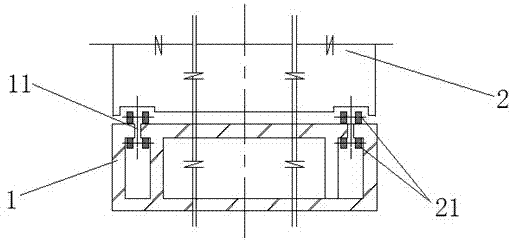

[0109] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

[0110] Such as Figure 1~Figure 12 As shown, 1. base, 11. chute, 2. mobile platform, 21. mobile wheel, 22. bearing, 23. motor, 24. clutch converter, 3. half shaft, 4. half shaft connector, 41. Connector bolts, 42. Connector nuts, 5. Positioning disc, 51. Positioning disc sleeve, 510. Hydraulic nozzle, 511. Sub-hydraulic pipe, 512. Sub-hydraulic ring, 513. Hydraulic tube bundle, 514. Total hydraulic pipe ring, 515. Closed middle plate, 516. Return spring, 517. Reserved hole, 518. Reserved hole bolt, 52. Disc sleeve bolt, 53. Fixed strut, 54. Movable strut, 55. Adjusting strut, 56. Positioning ring, 57. Positioning ring bolt, 58. Positioning clamp, 591. Joint sleeve, 592. Consolidation end, 593. Overhang end, 594. Joint hole, 6. Positioning support, 61. Positioning support sleeve, 62. Support Set of bolts, 7. Reinforcement cage, 71. Reinforcement ring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com