Automatic welding and forming machine of tapered pole reinforcing cage

An automatic welding and forming machine technology, applied in welding equipment, resistance welding equipment, applications, etc., to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

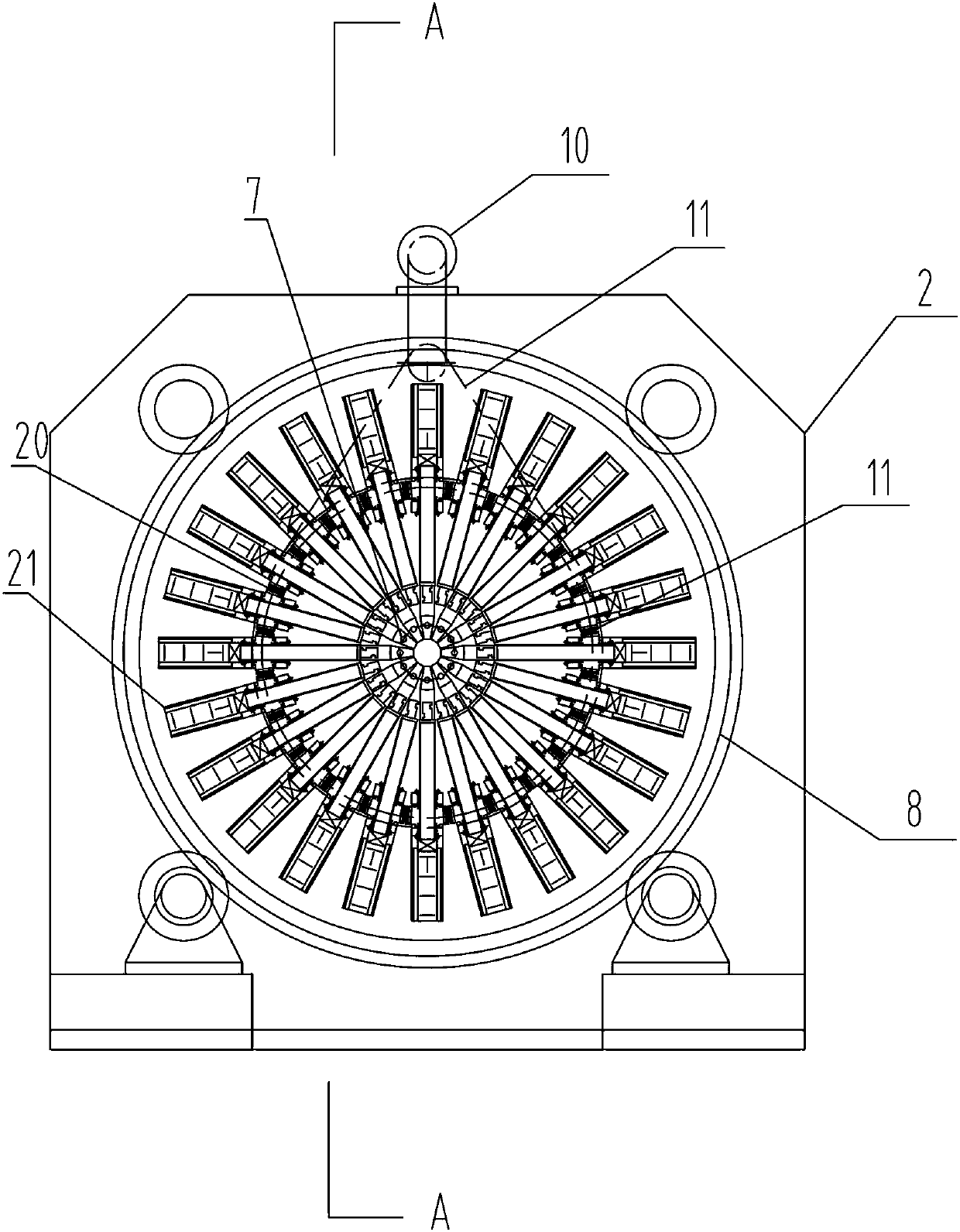

[0022] Such as figure 1 As shown, the automatic welding and forming machine for steel cages with tapered electric poles includes a material rack 1, a steel cage forming mechanism 2, a moving and rotating mechanism 3, and a welding device 4. The material rack 1 and the reinforcing cage forming mechanism 2 are arranged on the bottom bracket 5, The moving and rotating mechanism 3 is arranged on the track mechanism 6 of the bottom bracket 5 .

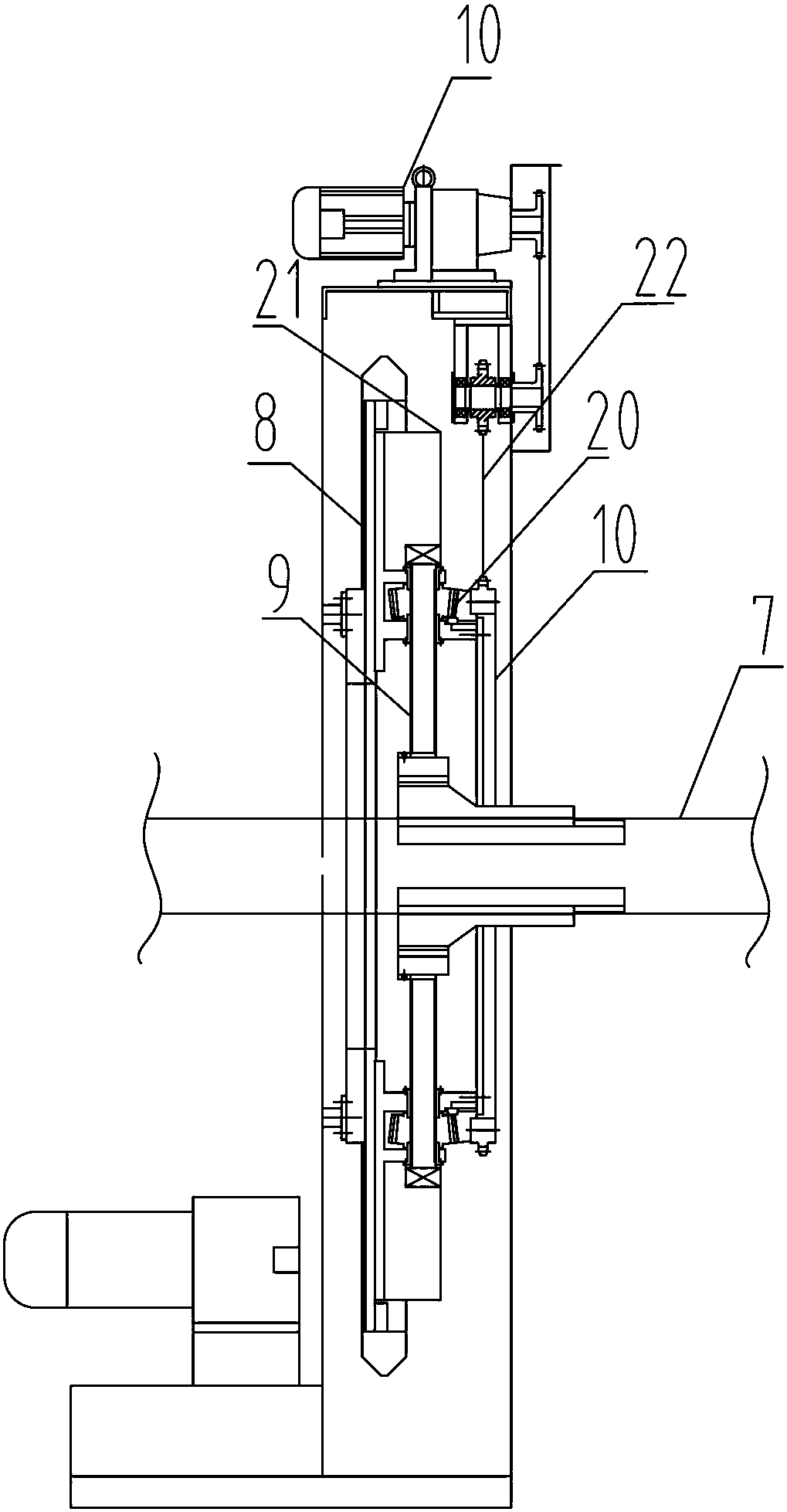

[0023] Such as figure 2 , image 3 As shown, the reinforcement cage forming mechanism 2 includes a second driving device and a rotating disk 8 driven by the second driving device. The rotating disk 8 is also provided with a third driving device 10, a large ring gear 11, a pinion 20, and 20 sets of pinions. At one end of the positioning device 9, the large ring gear 11 is transmitted to the pinion 20 through the chain 22, and the pinion 20 is transmitted to one end of the positioning device 9 to realize the movement of the positioning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com