Automatic welding device of reinforcement cage seam welder

A technology of automatic welding and seam welding machine, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the production efficiency and quality of steel cages, irregular solder joints, and high labor intensity of workers. Fast, guaranteed welding quality, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

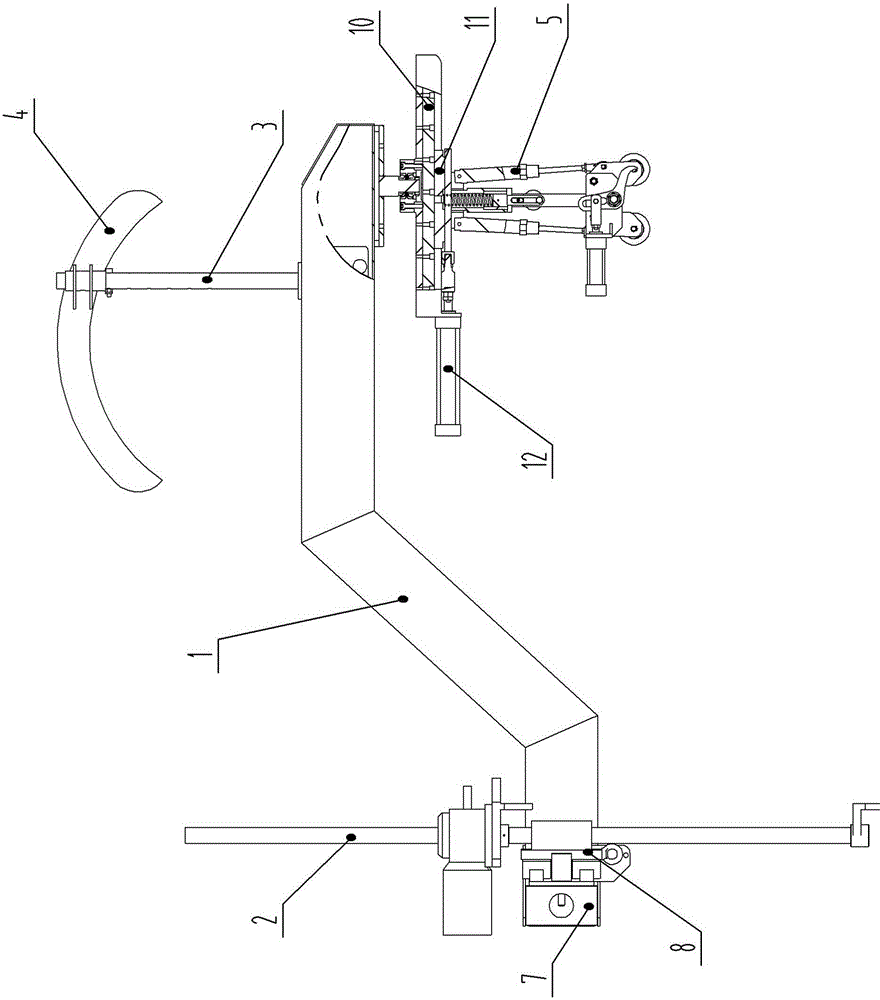

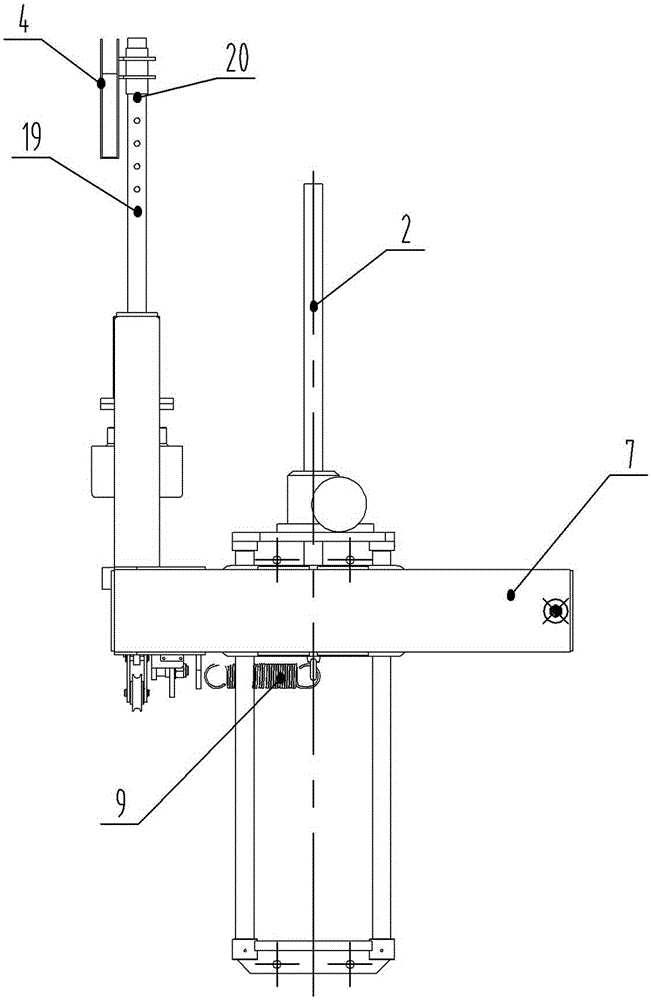

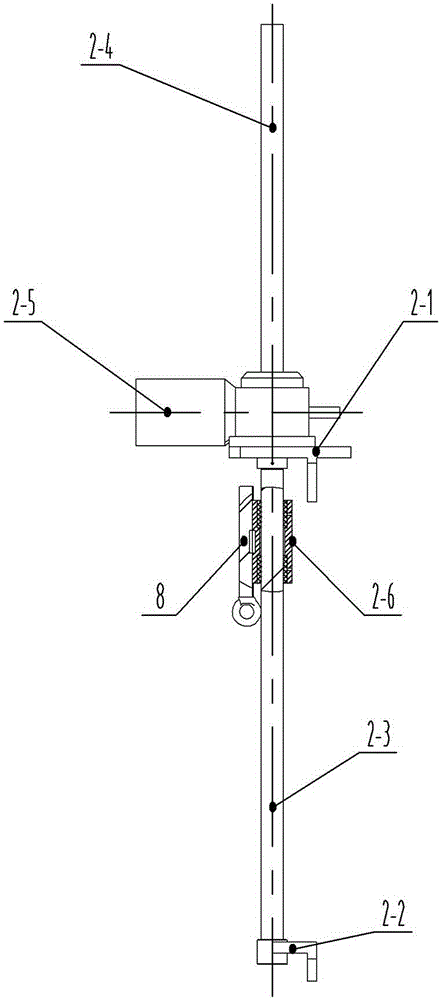

[0029] see Figure 1-2 , 5. In the figure, the automatic welding device of the steel cage roll welding machine of the present invention includes a welding support arm 1 and its lifting mechanism 2, a welding wire support rod 3 and its arc bracket 4, a welding hand mechanism 5 and a welding handle clamping mechanism 6. The welding support arm is a "Z"-shaped structure arranged horizontally, and the lower end of the welding support arm is longitudinally provided with a linear track Ⅰ7 and a slider Ⅰ8 that is slidingly matched with it. The slider Ⅰ is fixedly connected to the lifting mechanism. A tension spring 9 is longitudinally arranged between the block I and the linear track I, and a welding wire support bar and its arc bracket are arranged on the top of the upper end of the welding support arm, and a linear track II10 is provided at the bottom of the upper end of the welding support arm and slides with it. The matched and connected slide block II11 is provided with a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com