Pile foundation steel bar cage manufacturing method

A manufacturing method and technology of steel cages, which are applied in foundation structure engineering, sheet pile walls, manufacturing ring nets with wires, etc., can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

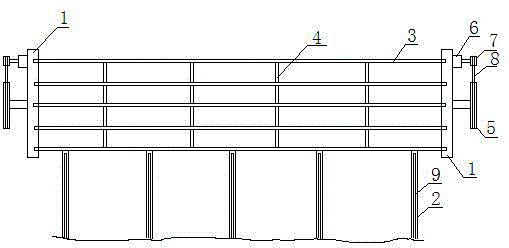

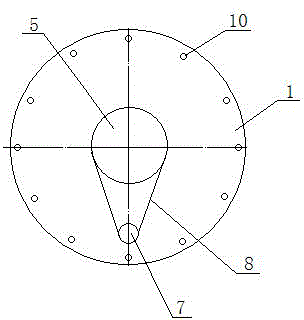

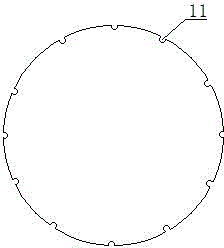

[0019] Such as figure 1 , figure 2 , image 3 Shown, a kind of pile foundation reinforcement cage manufacturing method comprises the following steps:

[0020] (1) Concrete arc-shaped groove 2 is poured on the ground. Of course, the groove 2 can also be made of other materials. The bottom of the groove 2 is arc-shaped, and the grooves 2 are arranged in a straight line. The grooves 2 are parallel to each other, and the stirrups 9 used to make the steel cage are laid in the grooves 2, and the grooves 2 are compatible with the stirrups 9; The width of the section is greater than the diameter of the stirrup 9 by 1-3 mm, so as to prevent the stirrup 9 from being stuck in the groove 2;

[0021] (2) Positioning discs 1 are arranged on both sides of the first groove 2 and the last groove 2 respectively, and the two positioning discs 1 are facing each other, and are evenly arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com