Double-welding mechanism of reinforcement cage seam welder

A double welding and rolling welding machine technology, which is applied in three-dimensional seam welding, roller electrode welding, welding equipment and other directions, can solve the problems of not meeting production needs, low production efficiency, etc., and achieves a wide range of specifications, low cost, welding Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

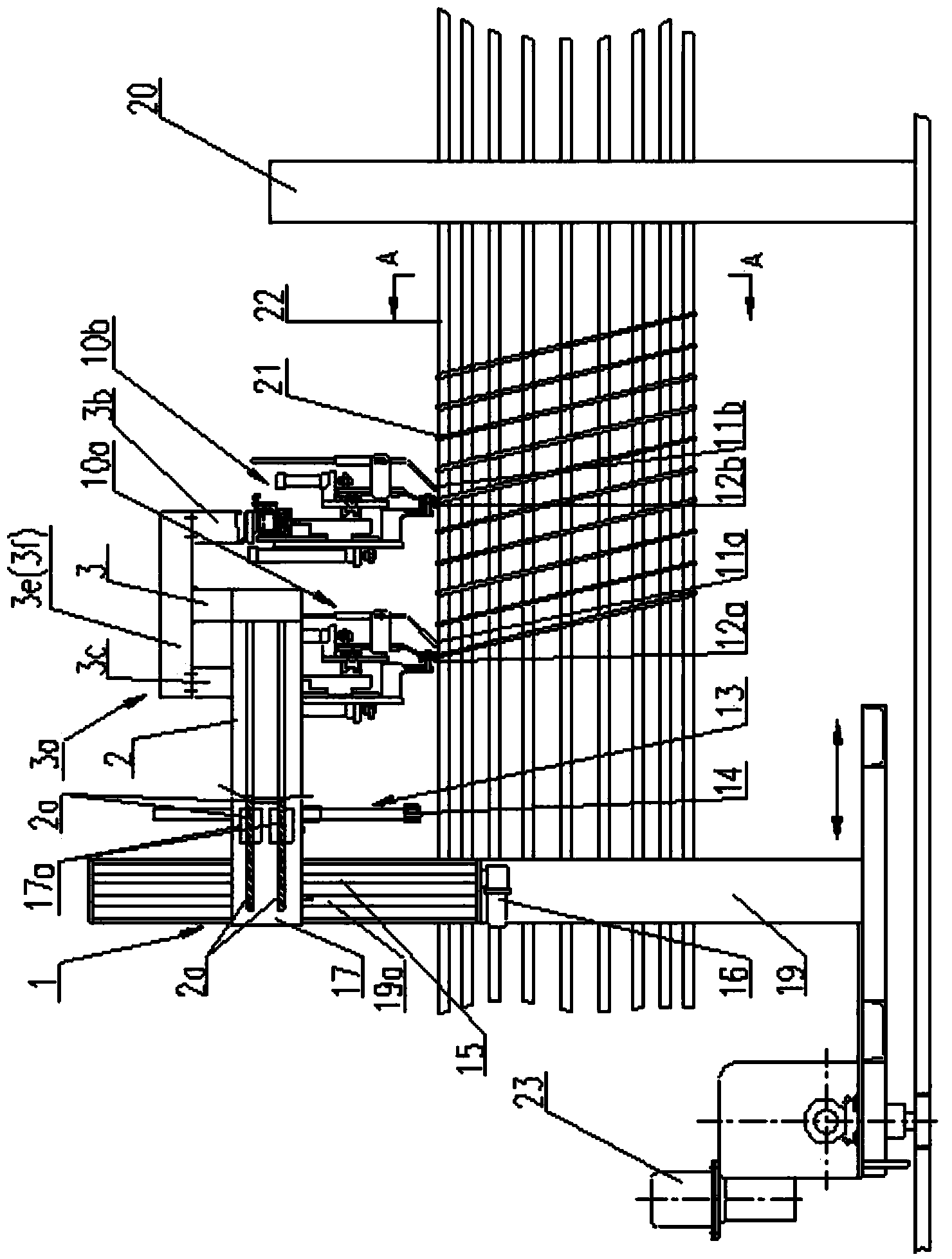

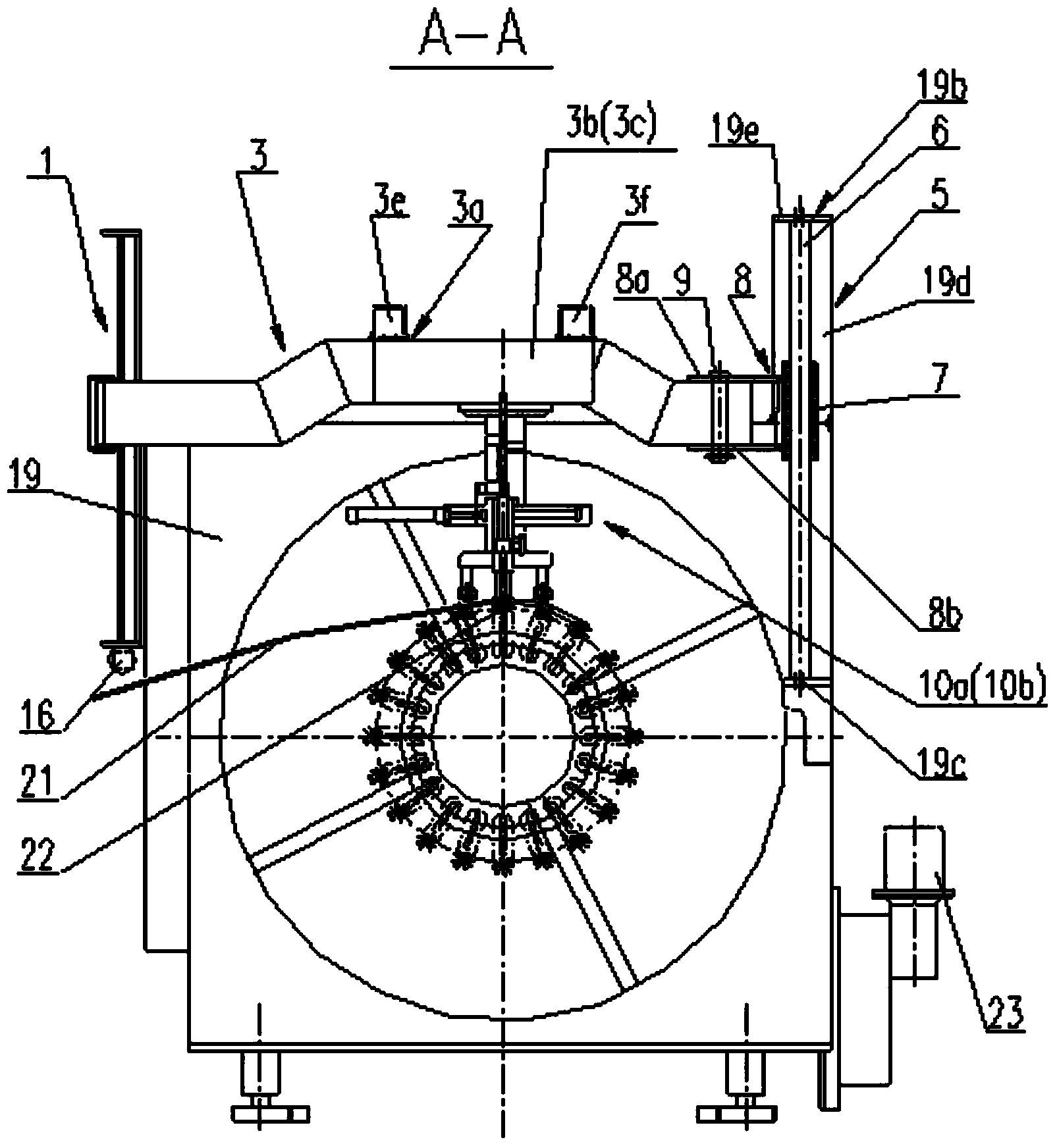

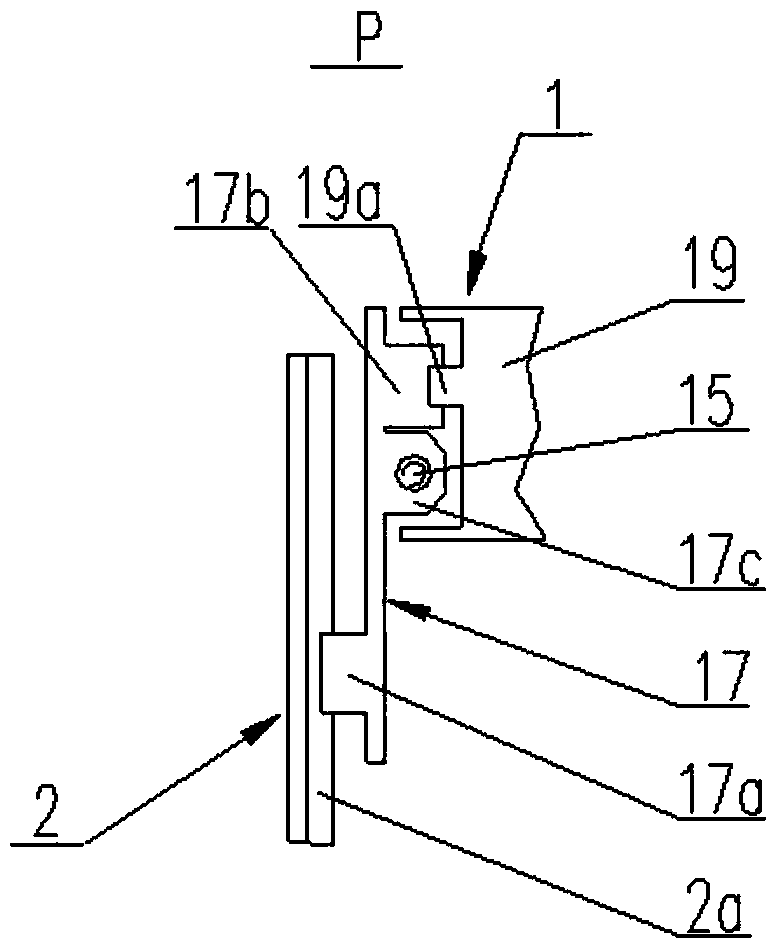

[0023] The implementation of the present invention will be further detailed below in conjunction with the accompanying drawings.

[0024] As shown in the figure, the present invention provides a double welding mechanism of a steel cage seam welding machine. The double welding mechanism includes: a moving turntable 19 equipped with longitudinal ribs 22, and a mounting arm 3; installation on the front side of the moving turntable 19 The arm 3 is equipped with a first set of welding torch devices 10a and a second set of welding torch devices 10b. The first set of welding torch devices 10a and the second set of welding torch devices 10b are spaced and arranged side by side along the longitudinal rib 22; the two ends of the mounting arm 3 are installed in a sliding manner. On both sides of the moving turntable 19, one side of the moving turntable 19 is provided with a welding gun position adjustment mechanism 1 that drives the mounting arm 3 to move up and down and horizontally. The ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com