Processing equipment of reinforcing steel bar frame for electric power construction

A processing equipment and electric power construction technology, applied in the direction of wire material processing, application, household appliances, etc., can solve the problems of labor-intensive processing, easy waste of steel bar ends, and irregular structure of steel bar frames, etc., to achieve convenient connection, convenient installation and interconnection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

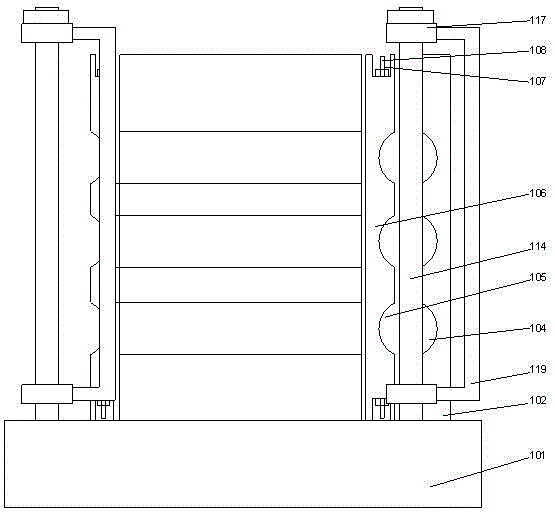

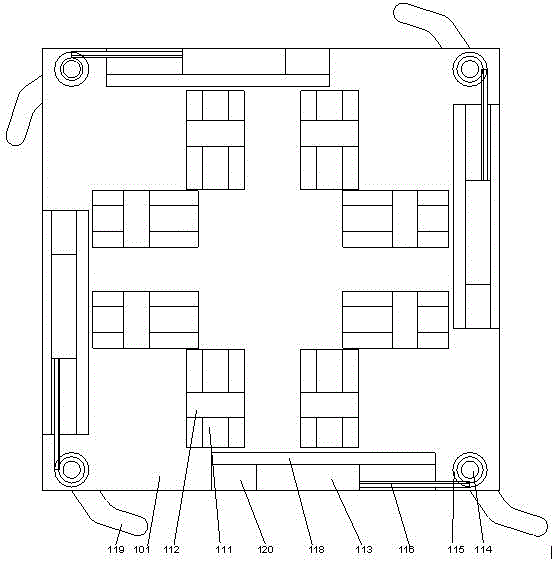

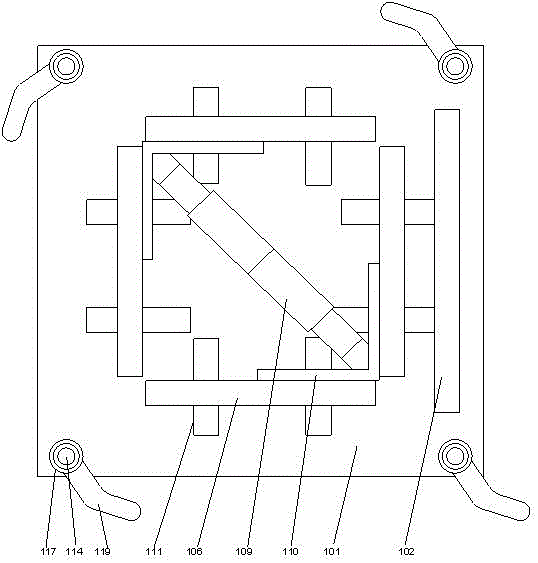

[0033] like Figure 1-3 As shown, a steel frame processing equipment for electric power construction includes a pressure bearing plate 102 and a support 101 arranged below the pressure bearing plate. The cross section of the support is quadrilateral. The inner wall of the plate is provided with grooves 104 for clamping steel bars, the grooves are at least 2 arranged at equal intervals along the height direction of the pressure bearing plate, and a positioning plate 106 is arranged above the support , there are four positioning plates, the four positioning plates form a quadrilateral structure, and the four positioning plates are provided with a slot 105 corresponding to the position of the groove;

[0034] Two cylinders 109 are arranged in the middle part above the support, and the two cylinders are located on a diagonal line of the support, and the two cylinders are arranged in reverse, and the two cylinders Pressure plates 110 are respectively arranged on the telescopic rod...

Embodiment 2

[0041] In this embodiment, in order to facilitate the fixing of the steel bar buckle, preferably, two sleeves 117 are arranged on the rotating shaft, and the two ends of the steel bar buckle are respectively fixedly connected to the outer wall of the sleeve. . The steel bar buckle is fixed on the rotating shaft through the sleeve.

[0042] In order to further facilitate the fixing of the sleeve, in this embodiment, preferably, an external spline is provided on the shaft, an internal spline is provided on the inner wall of the sleeve, and the sleeve and the shaft key connection.

[0043] In order to prevent the sleeve from moving along the axial direction of the rotating shaft, in this embodiment, an external thread is provided on the upper end of the rotating shaft, and a locking nut is sleeved on the top end of the rotating shaft. The movement of the sleeve is limited by the lock nut, so that it is relatively fixed on the rotating shaft.

[0044] In order to facilitate the...

Embodiment 3

[0049] On the basis of Embodiment 1, this embodiment discloses a method for processing a steel frame with a steel frame processing equipment for electric power construction, including the following steps:

[0050] S1: Determine the side length of the steel bar frame, place the steel bar in the groove on the pressure bearing plate, start the cylinder, and make the cylinder push the positioning plate to move toward the side wall of the support, so that the card slot corresponds to the position of the groove, and the steel bar Located in the cavity formed by the card slot and the groove, mark the four hydraulic cylinders in the counterclockwise direction as the first hydraulic cylinder, the second hydraulic cylinder, the third hydraulic cylinder and the fourth hydraulic cylinder;

[0051] S2: Start the first hydraulic cylinder corresponding to the rotating shaft on one side of the pressure bearing plate, so that the first hydraulic cylinder pushes the corresponding rack to move, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com