Telescopic bar distribution device for steel bar cage molding machine

A steel cage forming machine and telescopic technology, which is applied to the manufacture of ring mesh, other household appliances, household appliances, etc., can solve the problems of large floor area, high processing cost, large waste of materials and energy, etc., and achieve Small footprint, low processing cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

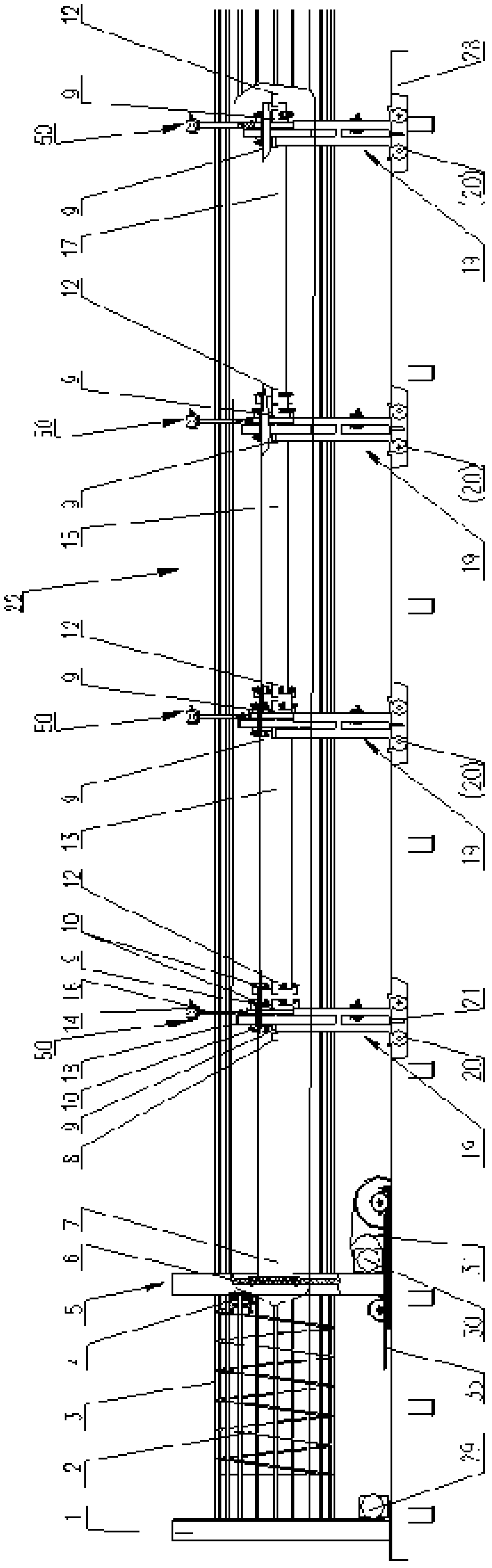

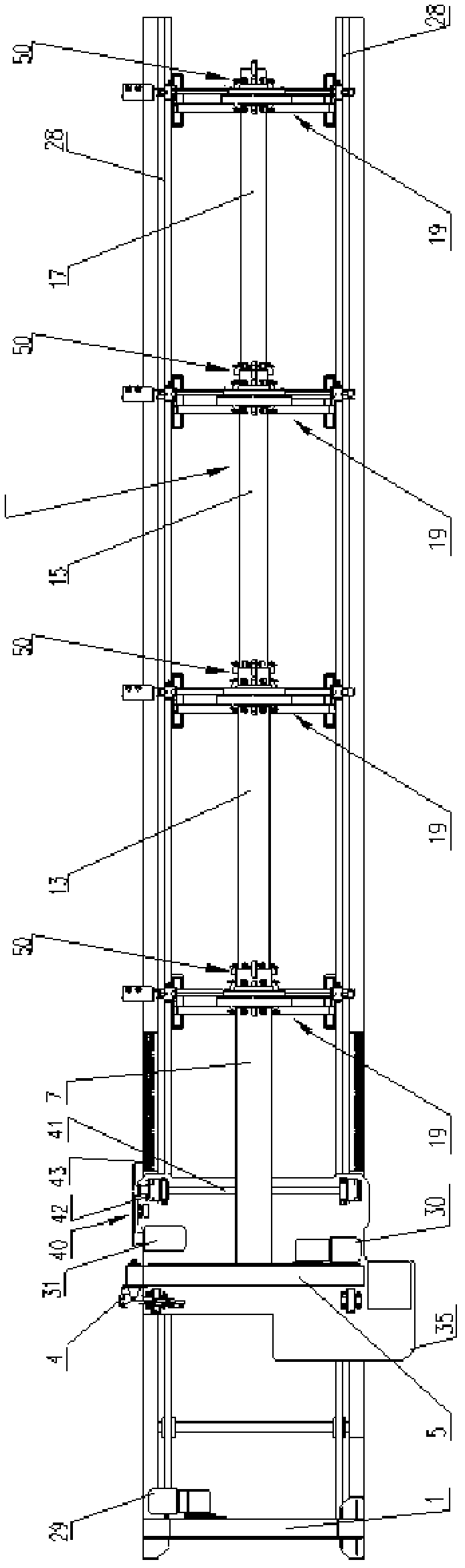

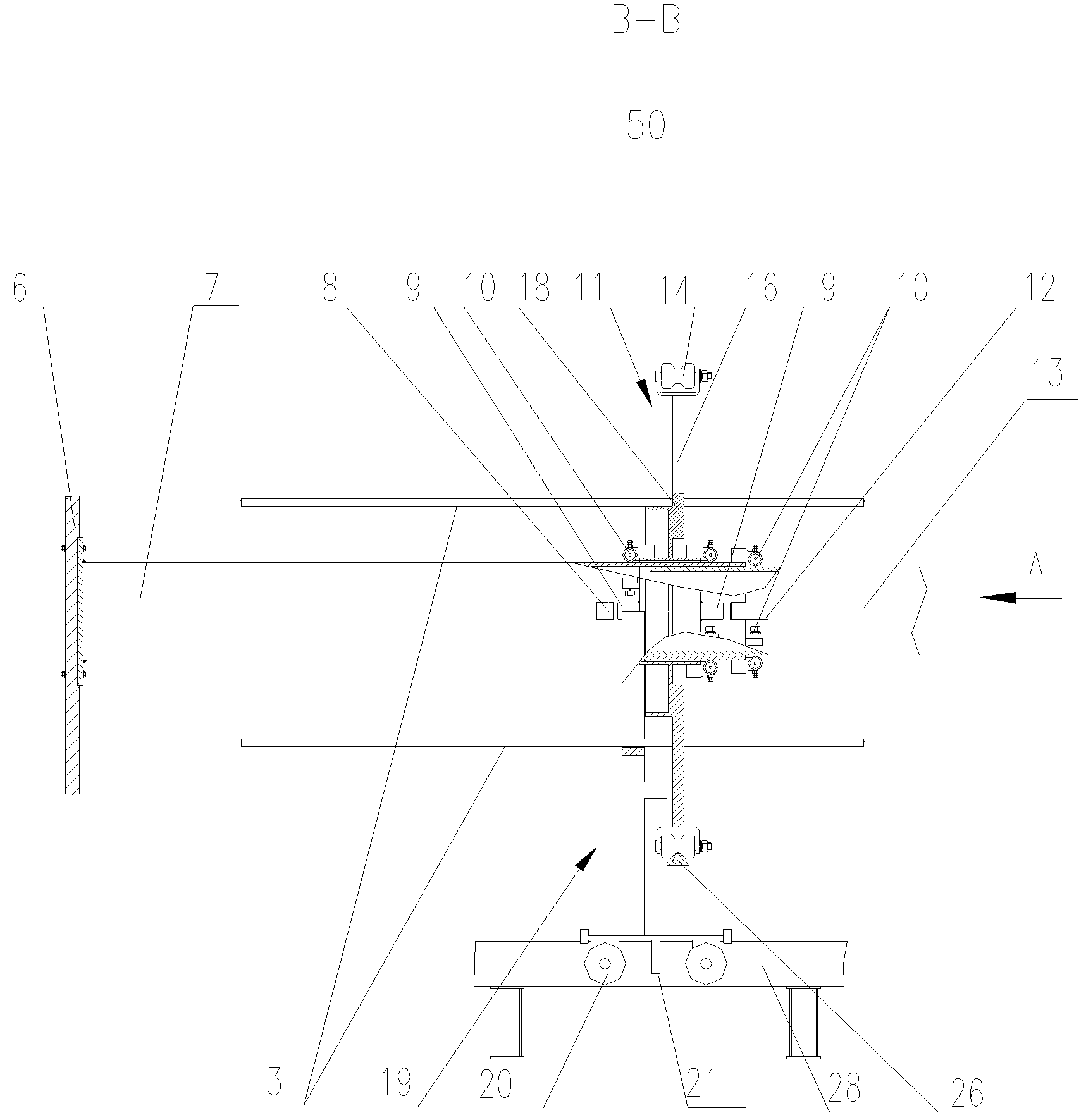

[0020] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The present invention provides a telescopic reinforcement device for a steel cage forming machine. The steel cage forming machine includes a fixed plate 1 and a movable plate 5, and a rotating plate connected to a fixed plate motor 29 is provided in the fixed plate 1 (not shown in the figure) The moving plate 5 is provided with a turntable 6 that runs through and drives the main ribs 3 to rotate. The turntable 6 is connected to the moving plate rotating motor 30. The moving plate 5 moves on the bottom beam 28. The moving plate 5 and the moving device that drives it to move along the bottom beam 28 , Stirrup 2 welding devices are all fixed on the mobile plate 35; the mobile device includes: the mobile plate mobile drive unit 31 drives the mobile shaft 41 to rotate through the sprocket chain transmission mechanism 40, and the fixed walking spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com