Cadmium-nickel contaminated soil remediator and preparation method

A technology of contaminated soil and remediation agent, which is applied in the field of remediation agent and preparation of cadmium-nickel contaminated soil, which can solve problems such as human health hazards and reduce the quality of agricultural products, and achieve the effects of increasing biomass, reducing mobility, and enhancing passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

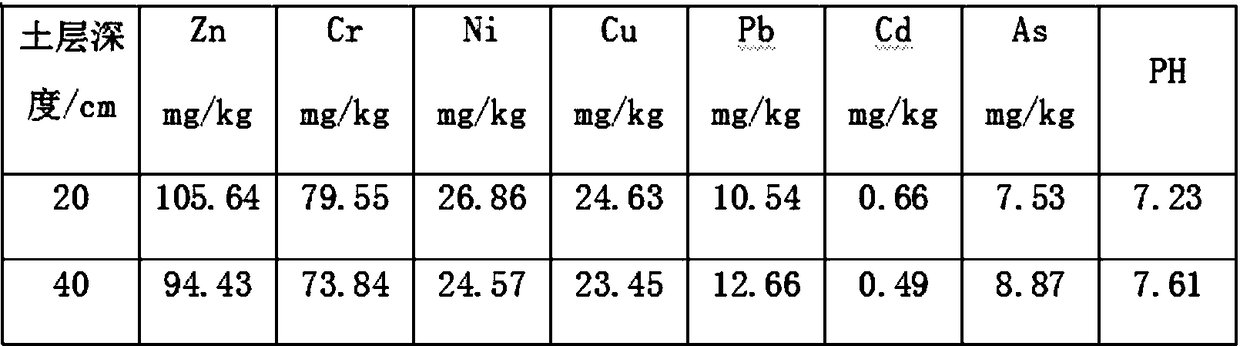

Method used

Image

Examples

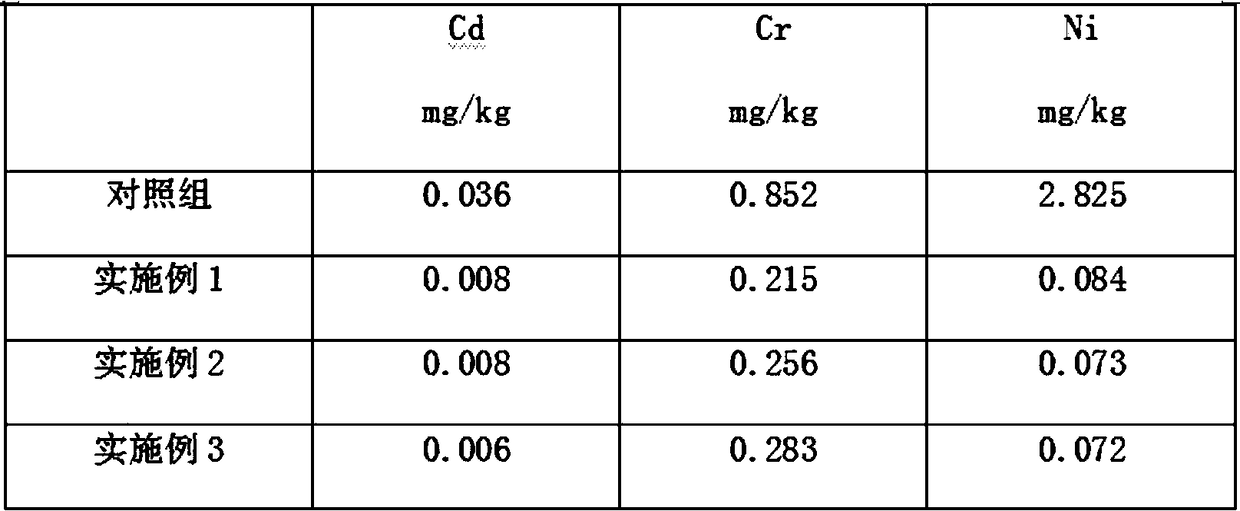

Embodiment 1

[0025] A kind of cadmium-nickel contaminated soil remediation agent provided by the present embodiment comprises the following components in parts by weight: biochar 70kg, oxalic acid activated phosphate rock powder 5kg, zinc fertilizer 2kg, lime 4kg, fly ash 10kg.

[0026] Among them, the preparation process of biochar is as follows: use rice husk to pyrolyze biochar under 510°C anoxic condition; dry at 50°C, finely grind the ingredients, and pass through a 100-mesh sieve.

[0027] Among them, the preparation steps of oxalic acid activated phosphate rock powder are as follows: mix oxalic acid and phosphate rock powder evenly according to the liquid-solid ratio of 12:1, and the concentration of oxalic acid is 0.4mol / L; the mixed solution is placed in a constant temperature environment of 26°C for 5 days activation ; After activation, dry at 50°C, then finely grind the ingredients and pass through a 100-mesh sieve.

[0028] Wherein, the zinc fertilizer comprises the following c...

Embodiment 2

[0040] A kind of cadmium-nickel contaminated soil remediation agent provided by the present embodiment comprises the following components in parts by weight: biochar 80kg, oxalic acid activated phosphate rock powder 7kg, zinc fertilizer 3kg, lime 5kg, fly ash 13kg.

[0041] Among them, the preparation process of biochar is as follows: use rice husk to pyrolyze biochar under 513°C anoxic condition; dry at 50°C, finely grind the ingredients, and pass through a 100-mesh sieve.

[0042] Among them, the preparation steps of oxalic acid activated phosphate rock powder are as follows: mix oxalic acid and phosphate rock powder evenly according to the liquid-solid ratio of 12:1, and the concentration of oxalic acid is 0.4mol / L; the mixed solution is placed in a constant temperature environment of 28°C for 5 days activation ; After activation, dry at 50°C, then finely grind the ingredients and pass through a 100-mesh sieve.

[0043] Wherein, the zinc fertilizer comprises the following c...

Embodiment 3

[0055] A kind of cadmium-nickel polluted soil remediation agent provided by the present embodiment comprises the following components in parts by weight: biochar 90kg, oxalic acid activated phosphate rock powder 8kg, zinc fertilizer 4kg, lime 6kg, fly ash 15kg.

[0056] Among them, the preparation process of biochar is as follows: use rice husk to pyrolyze biochar under 515°C anoxic condition; dry at 50°C, finely grind the ingredients, and pass through a 100-mesh sieve.

[0057] Among them, the preparation steps of oxalic acid activated phosphate rock powder are as follows: mix oxalic acid and phosphate rock powder evenly according to the liquid-solid ratio of 12:1, and the concentration of oxalic acid is 0.4mol / L; the mixed solution is placed in a constant temperature environment of 30°C for activation for 6 days ; After activation, dry at 52°C, then finely grind the ingredients and pass through a 100-mesh sieve.

[0058] Wherein, the zinc fertilizer includes the following co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com