One-step nickel smelting system and one-step nickel smelting method

A technology of nickel matte and nickel sulfide, applied in the field of metallurgy, can solve problems such as high energy consumption, high conditions for feeding raw materials into the furnace, and high nickel content in smelting slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

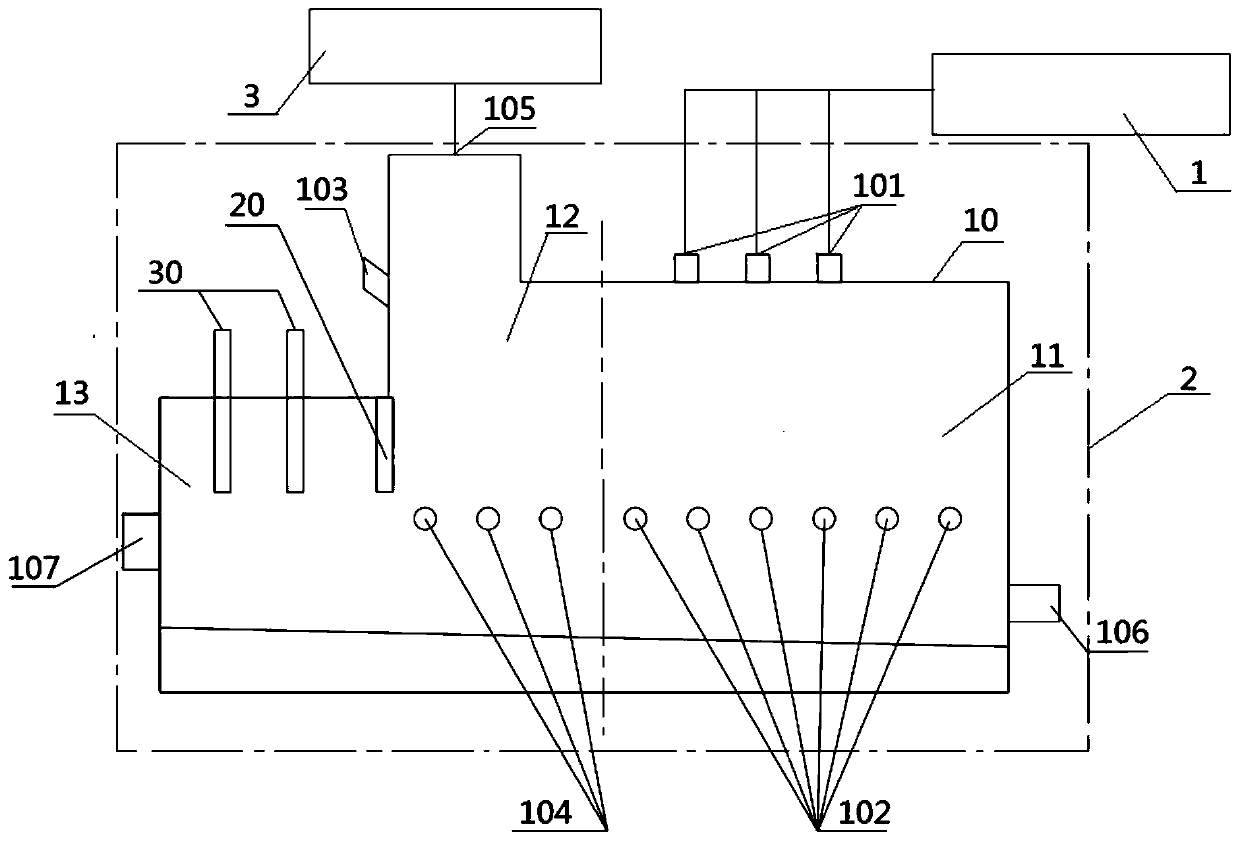

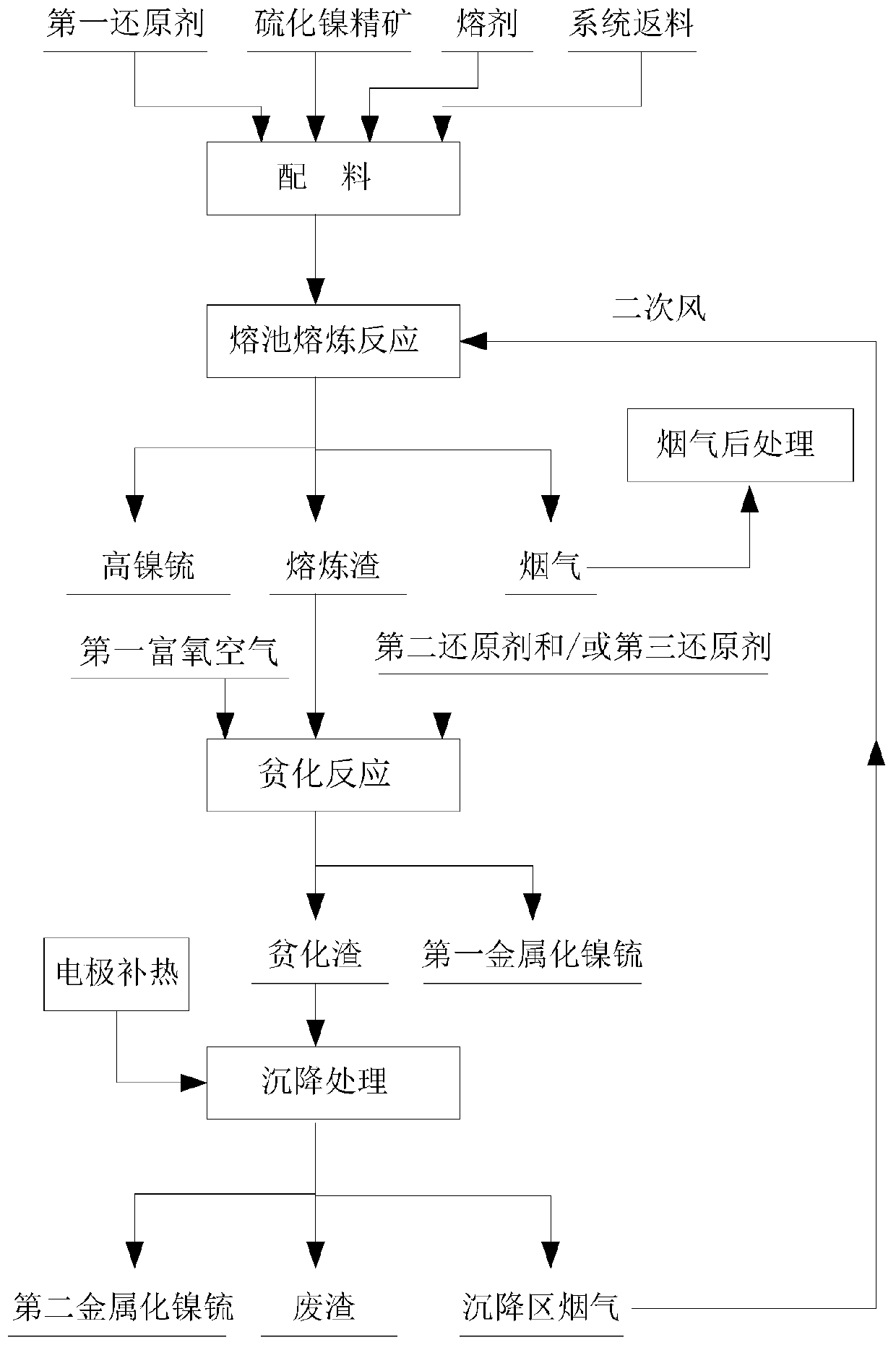

[0095] equipment such as figure 1 As shown, the smelting process is as follows figure 2 As shown, the specific process is as follows:

[0096] (1) Nickel sulfide concentrate ingredients: nickel sulfide concentrate (containing 7.72% Ni, 1.42% Cu, 0.27% Co, 40.5% Fe, 5.8% MgO), quartzite flux, reducing agent (anthracite) , System return materials (launder shell, smoke dust) are batched by quantitative feeder, and the weight ratio of each material is about: nickel concentrate: quartz stone flux: first reducing agent = 100:32:2.5, after batching, the mixed material passes through The belt conveyor is transported to the top of the melting furnace, and is added to the furnace by moving the belt conveyor.

[0097] (2) After batching, the mixed concentrate undergoes a series of chemical events such as decomposition and oxidation in the smelting zone of the smelting furnace and the oxygen-enriched air blown into the molten pool, resulting in high-nickel matte, smelting slag and flue...

Embodiment 2

[0103] equipment such as figure 1 As shown, the smelting process is as follows figure 2 As shown, the specific process is as follows:

[0104] (1) Nickel sulfide concentrate ingredients: nickel sulfide concentrate (6.0% Ni, 3.2% Cu, 0.18% Co, 28.5% Fe, 8.2% MgO), quartzite flux, reducing agent (coke) , System return material (launder shell, smoke dust) is batched by quantitative feeder, and the weight ratio of each material is about: nickel concentrate: quartz stone flux: first reducing agent = 100:15.6:6.0, after batching, the mixed material passes through The belt conveyor is transported to the top of the melting furnace, and is added to the furnace by moving the belt conveyor.

[0105] (2) After batching, the mixed concentrate undergoes a series of chemical events such as decomposition and oxidation in the smelting zone of the smelting furnace and the oxygen-enriched air blown into the molten pool, resulting in high-nickel matte, smelting slag and flue gas. The generate...

Embodiment 3

[0111] equipment such as figure 1 As shown, the smelting process is as follows figure 2 As shown, the specific process is as follows:

[0112] (1) Nickel sulfide concentrate ingredients. Nickel sulfide concentrate (containing Ni19.53%, containing Cu1.11%, containing Co0.65%, containing Fe36.73%, containing MgO1.42%), quartzite flux, reducing agent (blue carbon), system return material (Launder shell, smoke and dust) are batched by quantitative feeder, and the weight ratio of each material is about: nickel concentrate: quartz stone flux: first reducing agent = 100:27.1:1.5. After batching, the mixed material is transported to The top of the melting furnace is fed into the furnace by a moving belt conveyor.

[0113] (2) After batching, the mixed concentrate undergoes a series of chemical events such as decomposition and oxidation in the smelting zone of the smelting furnace and the oxygen-enriched air blown into the molten pool, resulting in high-nickel matte, smelting slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com