Elastomer program-controlled combined machine tool

A combined machine tool and body engineering technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., to achieve the effects of improving production efficiency and finished product qualification rate, reducing processing costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

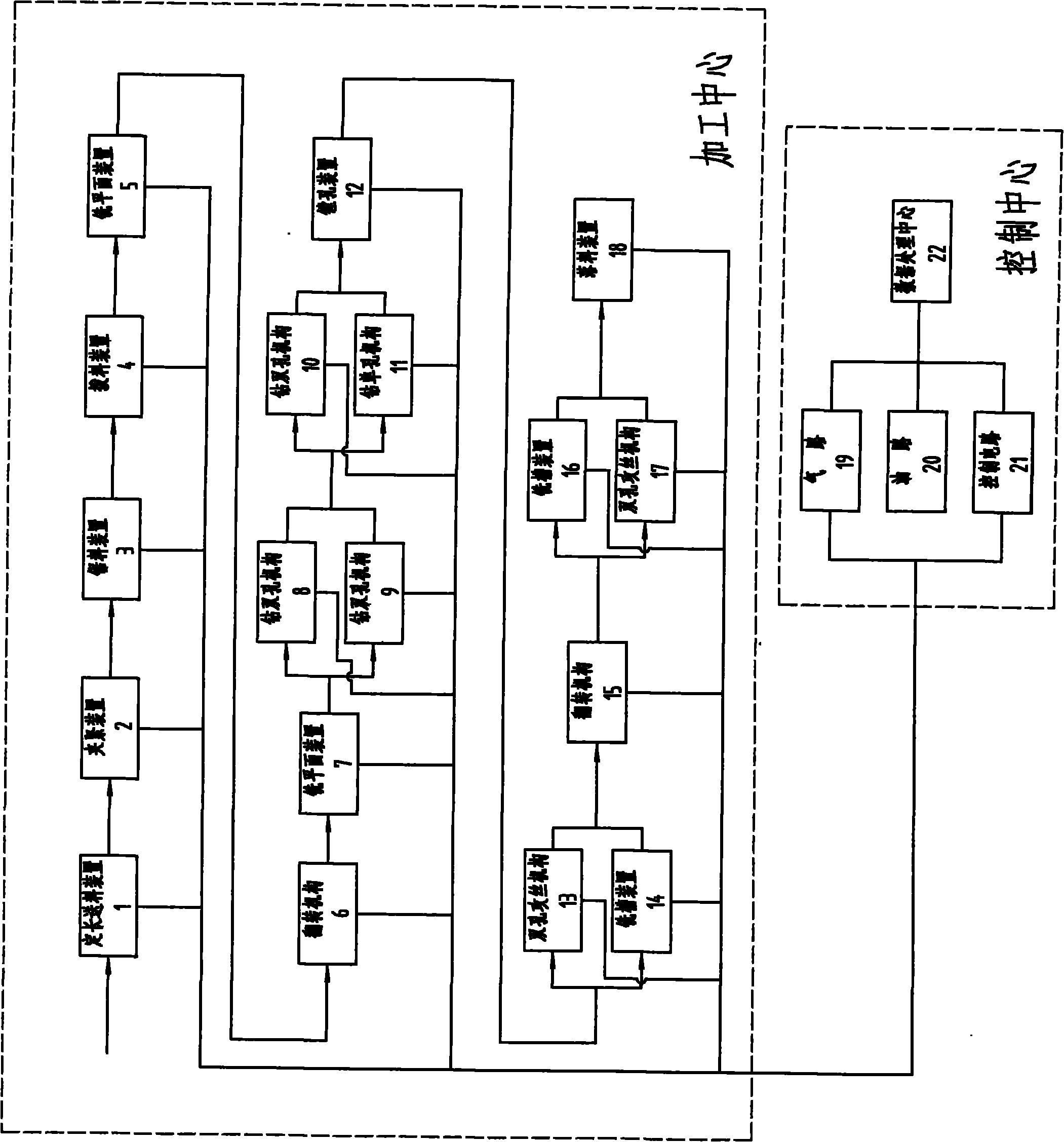

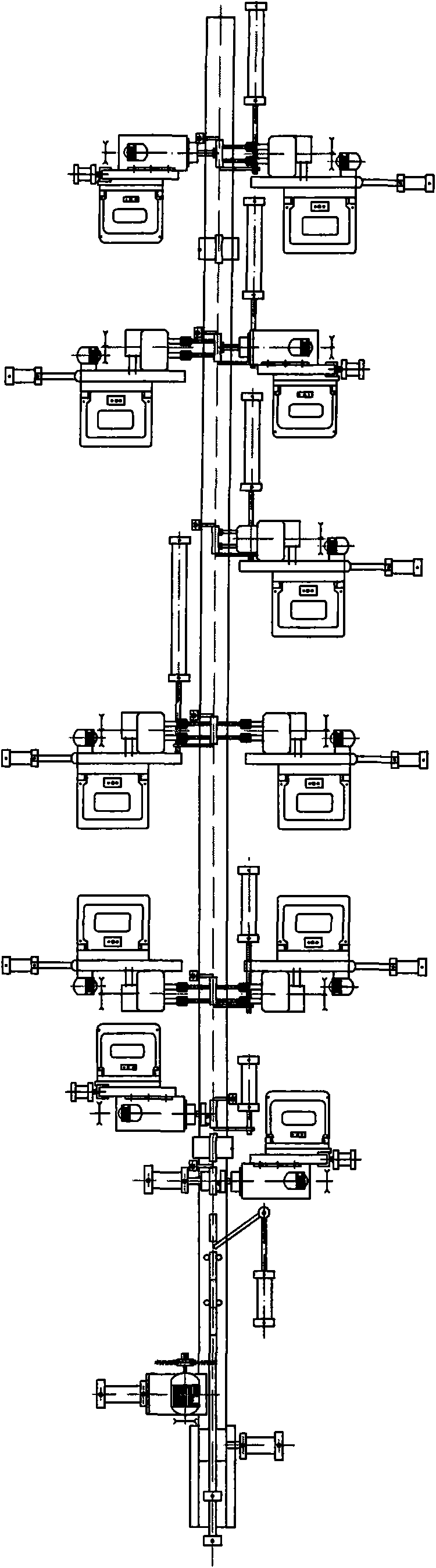

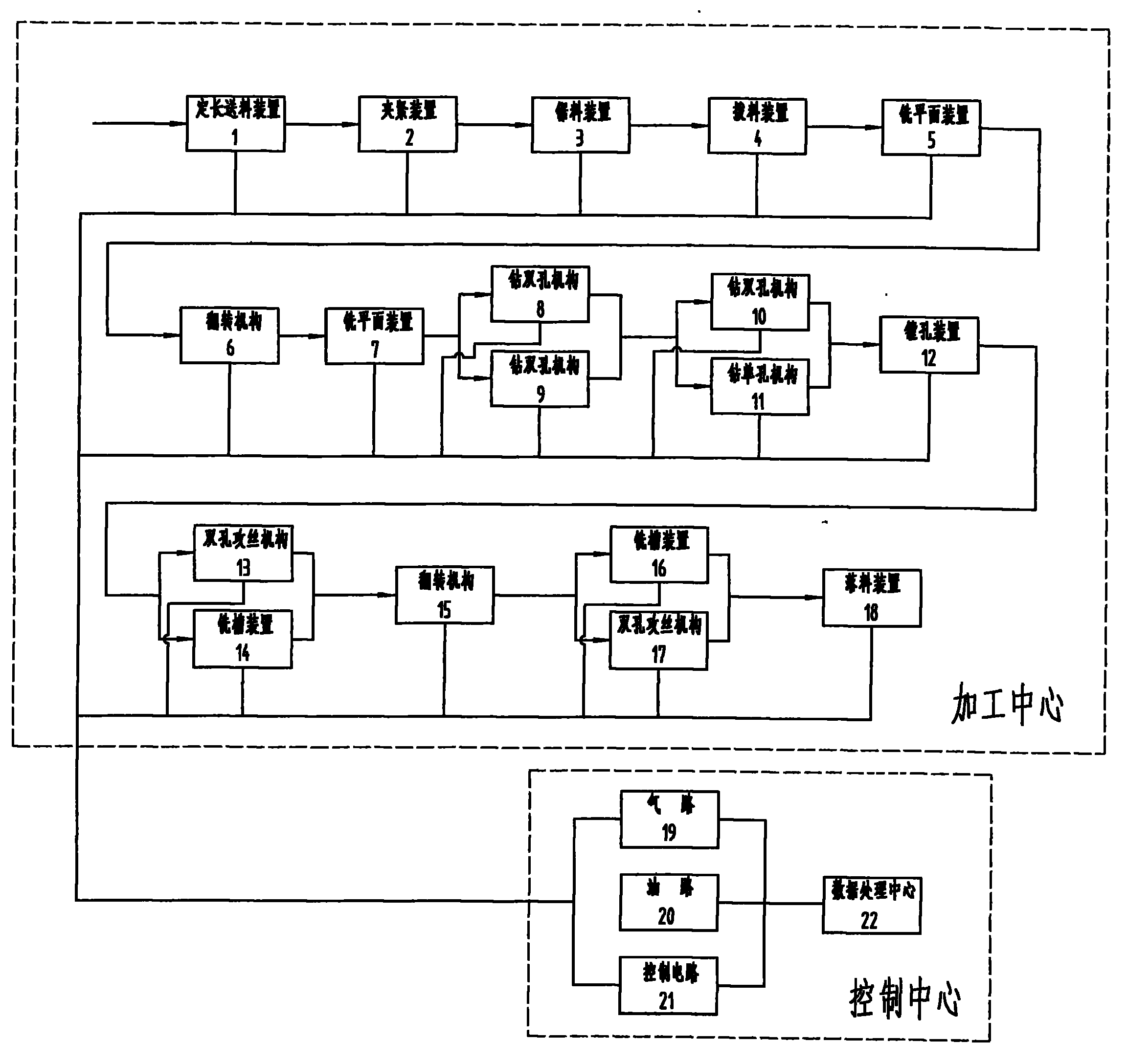

[0015] Such as figure 1 As shown, a kind of elastic body program-controlled combination machine tool of the present invention comprises control center, machining center, and wherein control center comprises data processing center 22 and respectively connected with it gas passage 19, oil passage 20, control circuit 21; Machining center comprises successively Connected fixed-length feeding device 1, clamping device 2, sawing device 3, feeding device 4, plane milling device 5, turning mechanism 6, plane milling device 7, double hole drilling mechanism 9, single hole drilling mechanism 11, boring Hole device 12, milling device 14, turning mechanism 15, double-hole tapping mechanism 17 and blanking device 18, in addition, a set of double-hole drilling mechanism 8 is connected on the double-hole drilling mechanism 9, and a set of double-hole drilling mechanism 8 is connected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com