Workpiece turnover and correction mechanism based on image identification

A technology of overturning correction mechanism and overturning mechanism, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of reduced product reliability and stability, increased labor intensity, and increased uncertain factors, so as to improve efficiency, Easy to operate, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

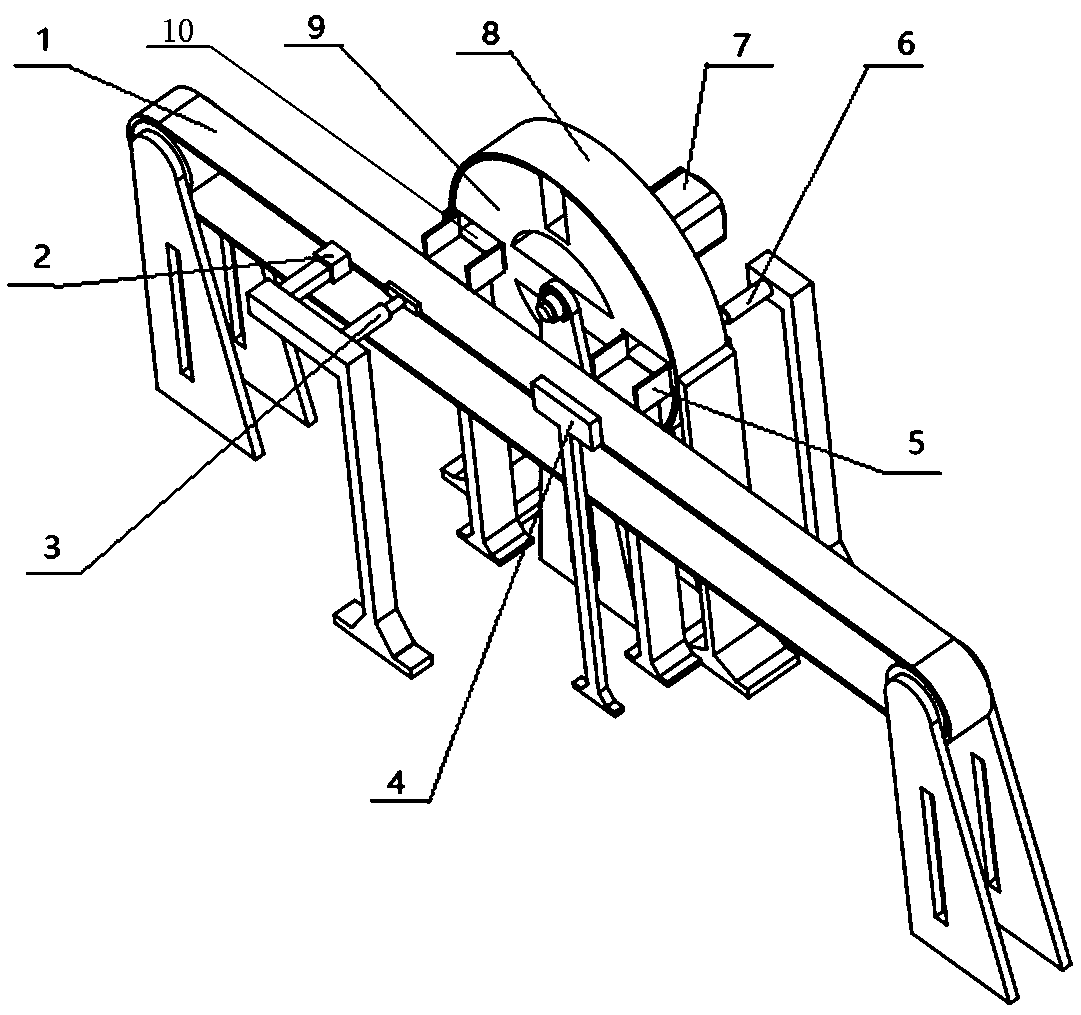

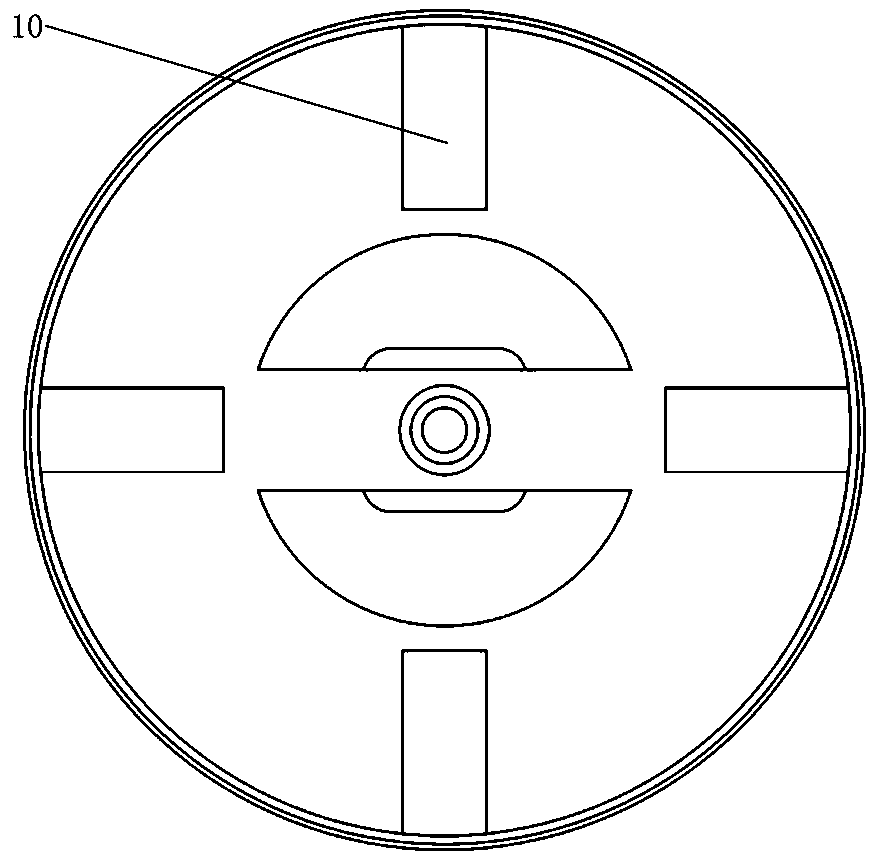

[0026] see figure 1 — Figure 5 , the present invention discloses a workpiece inversion correction mechanism based on image recognition, which includes a conveyor belt 1 for workpiece transmission, one side of the conveyor belt 1 is provided with an inversion mechanism 9, and both sides of the inversion mechanism 9 are equipped with internal Cavity-type storage space, two transition platforms 5 are provided on the side of the storage space close to the conveyor belt 1, and the transition platform 5 is aligned with the conveyor belt 1 and provided with a workpiece entrance, that is, figure 1 Among them, the rear of the two transition platforms 5 continues to extend into the turning mechanism 9, and there are two rectangular cavities for holding workpieces. The turning mechanism 9 and its storage space are driven by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com