Portal crane

A gantry crane and crane technology, applied in the direction of cranes, trolley cranes, traveling mechanisms, etc., can solve the problems of short sliding stroke of oil cylinders, frequent maintenance of wire ropes, short sliding distances, etc., and achieve high reliability and slippage. Lightweight and flexible, the effect of avoiding the trouble of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

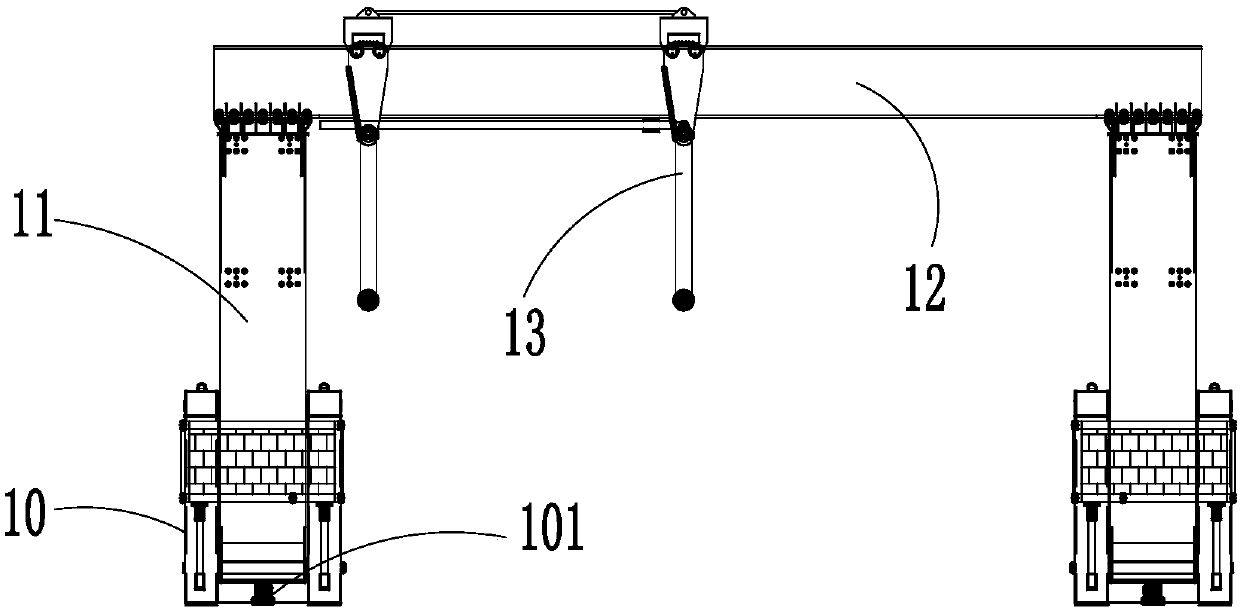

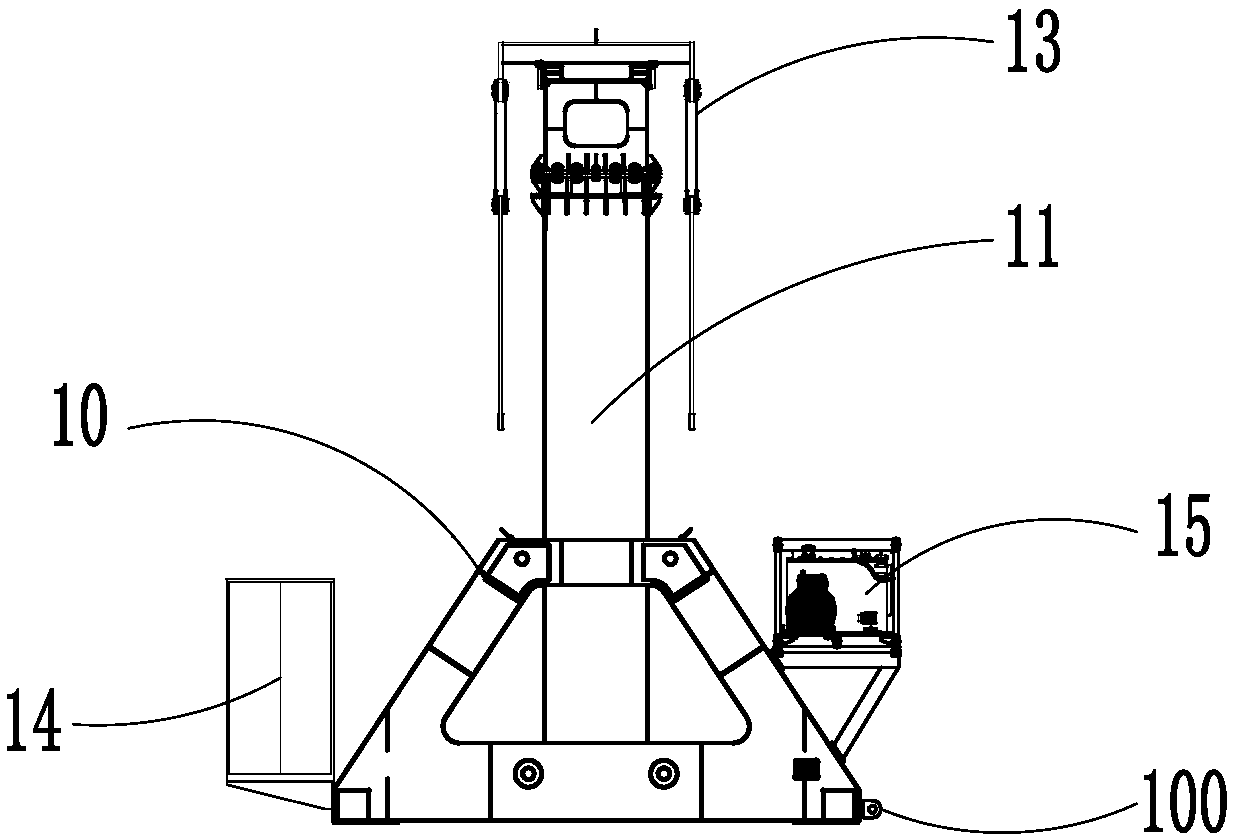

[0047] Such as Figure 5 , 6 Shown: in this embodiment: the moving mechanism includes the modular car 2, and the base 10 is fixed to the modular car 2 through the first connecting part 100.

[0048] The modular car 2 includes a frame, multiple suspension mechanisms and steering mechanisms arranged under the frame, and tires are connected below the suspension bracket. The suspension mechanism and the steering mechanism usually include a suspension cylinder and a steering cylinder. The modular car 2 is equipped with a special The hydraulic power station provides power for the suspension cylinder and the steering cylinder and drives them to travel. The modular car 2 and the lifting mechanism 11 can be respectively connected to a hydraulic power station or jointly connected to a hydraulic power station. Modular car 2 can be equipped with a remote control for walking, steering, and lifting. By operating the remote control, it can realize multiple actions of walking, steering, and lifti...

Embodiment 2

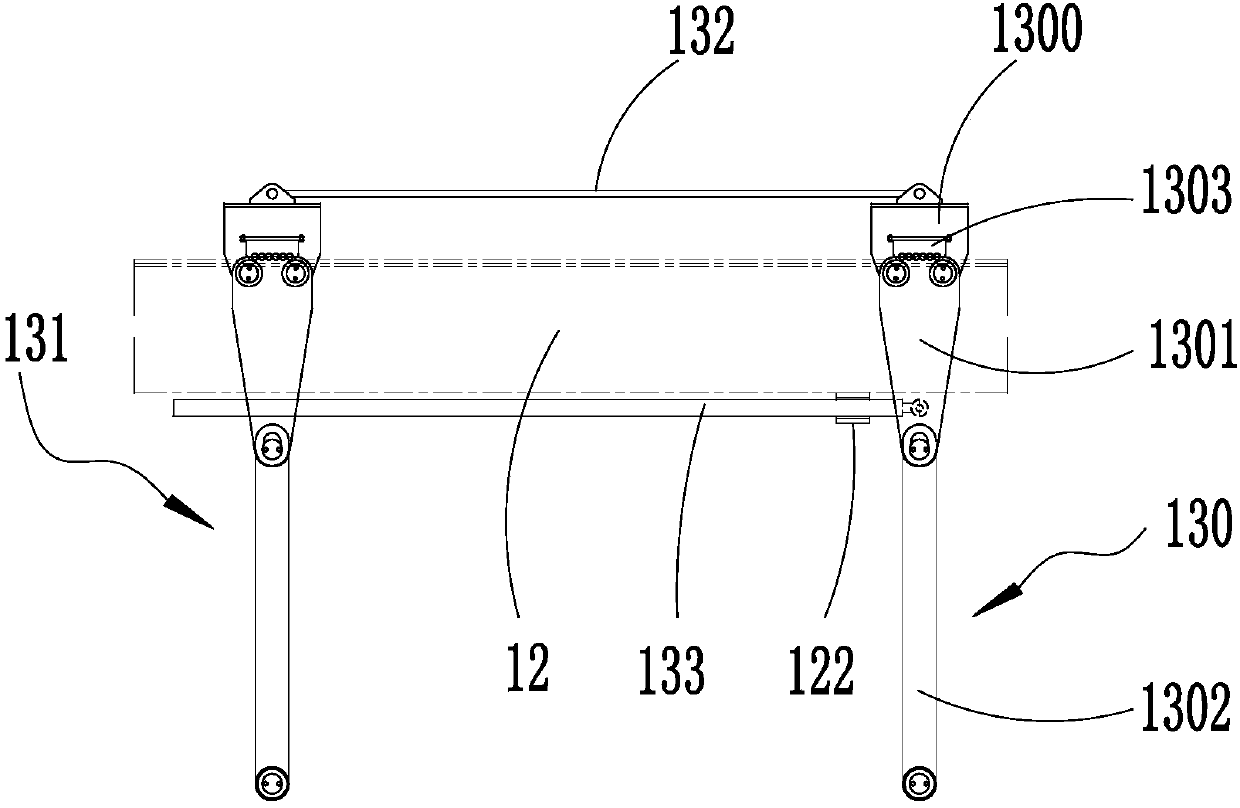

[0060] Such as Figure 7 , 8 Shown: In this embodiment: the moving mechanism includes a guide rail 30, a traveling cylinder 31, a guide bar is provided on the upper plane of the guide rail 30, and the guide groove at the bottom of the base 10 matches the guide bar, which can avoid the base 10 and its The deviation in the sliding process is prepared to ensure that the base 10 can advance in a predetermined direction under the push and pull of the traveling cylinder 31. The cylinder liner of the traveling cylinder 31 is connected to the guide rail 30, and the piston rod end of the traveling cylinder 31 is connected to the second connecting portion 101. Of course, the cylinder liner of the traveling cylinder 31 is connected to the second connecting portion 101, and the piston of the traveling cylinder 31 The rod end is connected to the guide rail.

[0061] When the crane body cooperates with the guide rail 30 for lifting and short-distance displacement, the following steps can be pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com