Workpiece shifting device

A technology of shifting device and workpiece, applied in the direction of metal processing, etc., can solve the problems of inability to synchronize the clearance between two working positions and increase the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

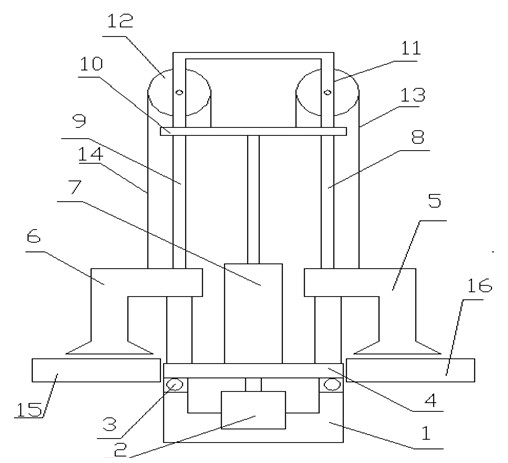

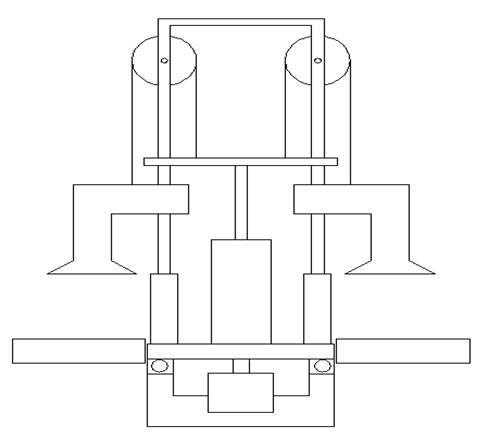

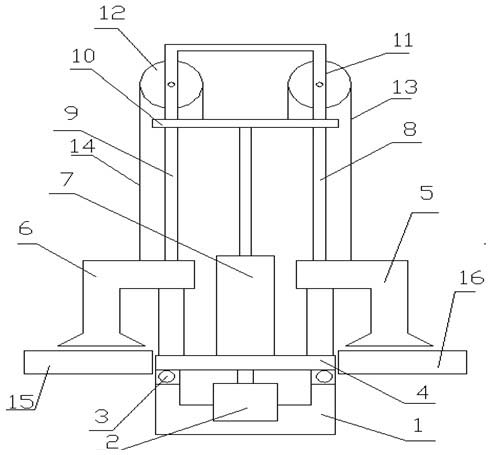

[0012] A workpiece shifting device, which includes a fixed base 1, a servo motor 2, a thrust bearing 3, a turntable 4, a left workpiece grabbing device 6, a right workpiece grabbing device 5, a cylinder 7, a left guide post 9, and a right guide post 8 , lifting plate 10, left pulley 12, right pulley 11, left flexible part 14, right flexible part 13, wherein, servomotor 2 and thrust bearing 3 are fixed on fixed base 1, and turntable 4 is installed on thrust bearing 3, turntable 4 Power connection with the output shaft of the servo motor 2; the turntable 4 is provided with a left guide post 9 and a right guide post 8; There are two holes, which are slidably matched with two left guide pillars 9, and there are two holes on the right workpiece grasping device 5, which are slidably matched with two right guide pillars 8; the left side of the lifting plate 10 has two holes, which are matched with two left The guide post 9 is slidably fitted, and the right side of the lifting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com