AGV charging station

A charging station and battery technology, applied in charging stations, electric vehicles, electric power devices, etc., can solve the problems of few functions, high cost, and low cost performance, and achieve the effect of high cost performance, low cost, and overall displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

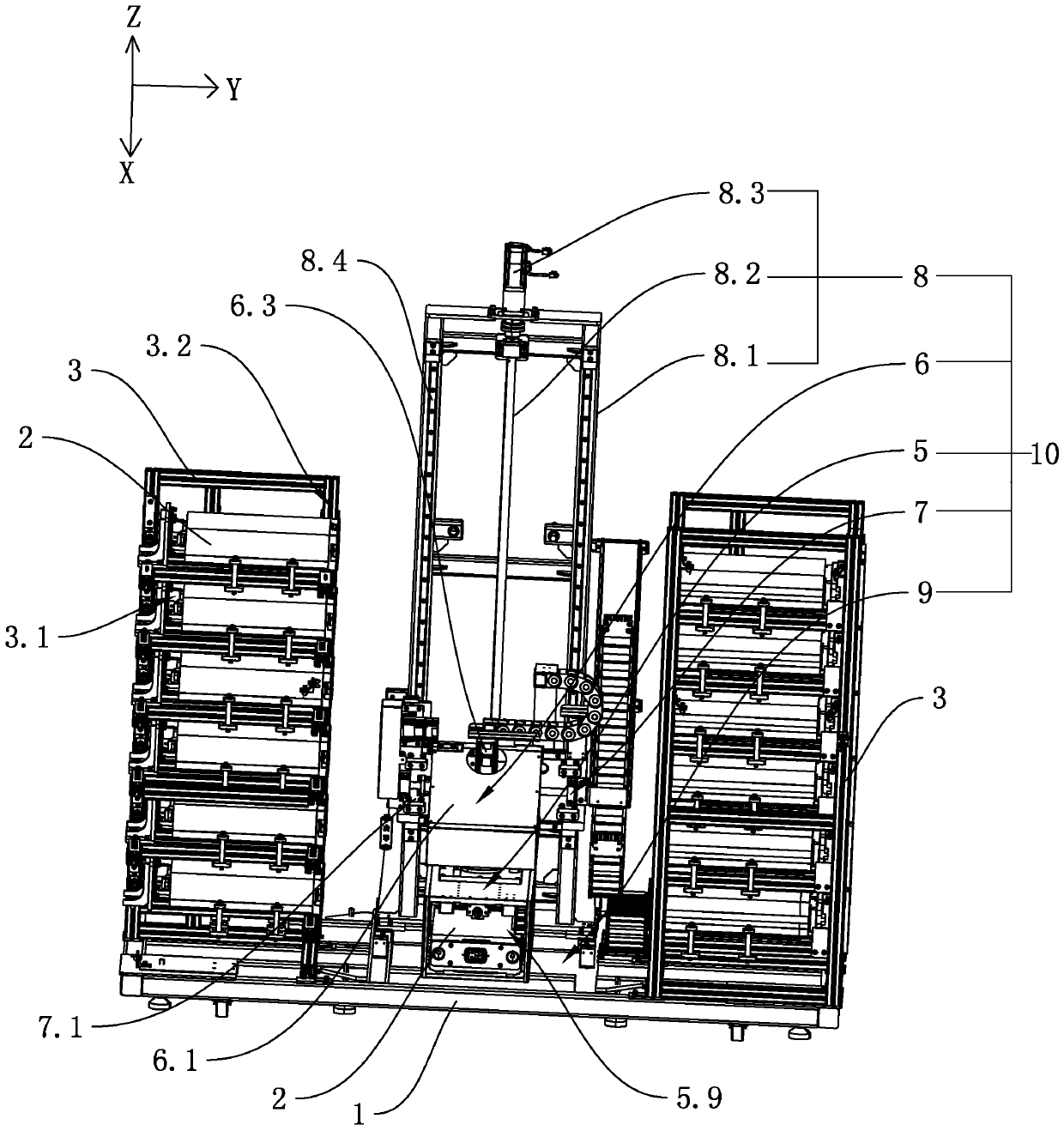

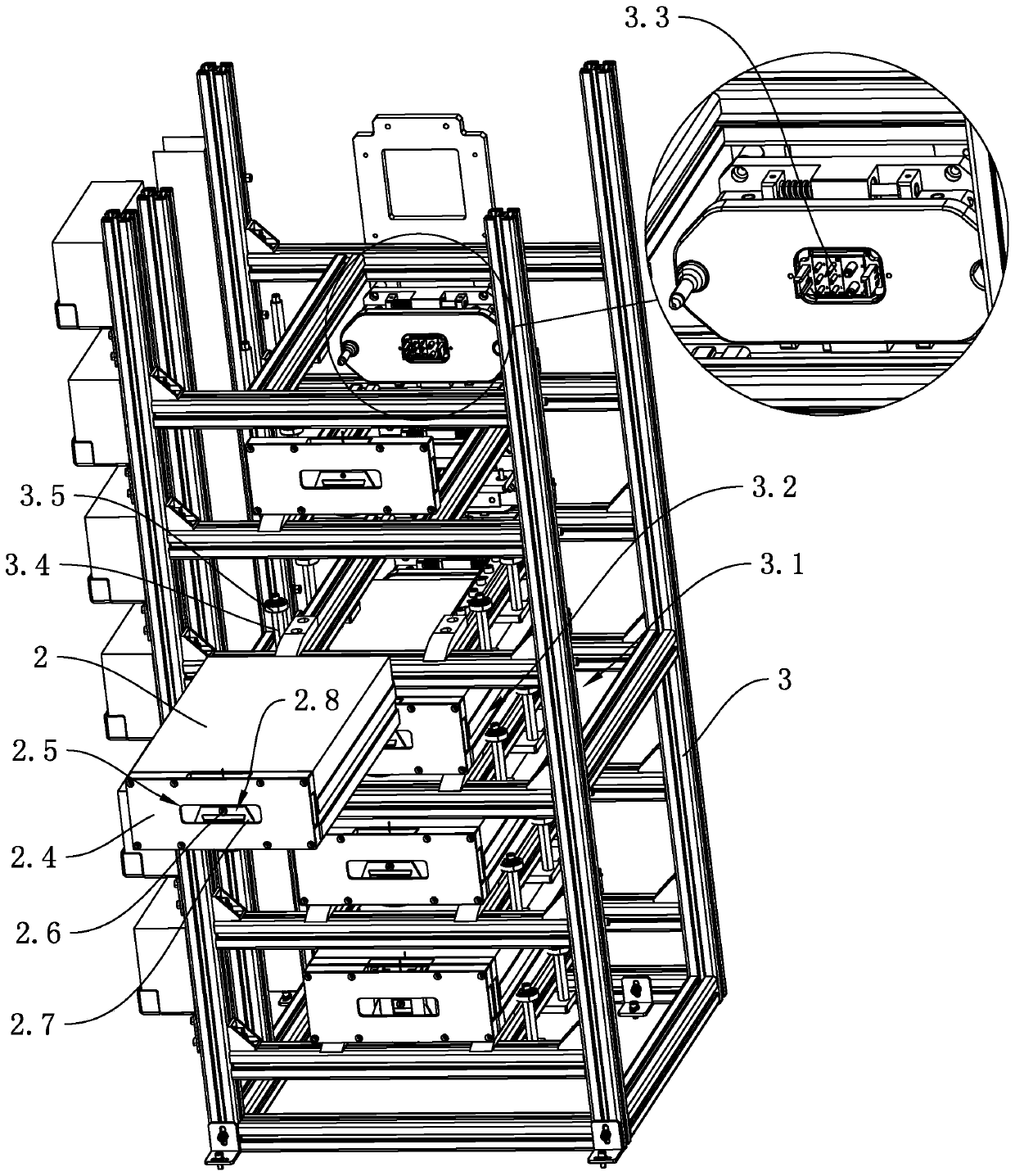

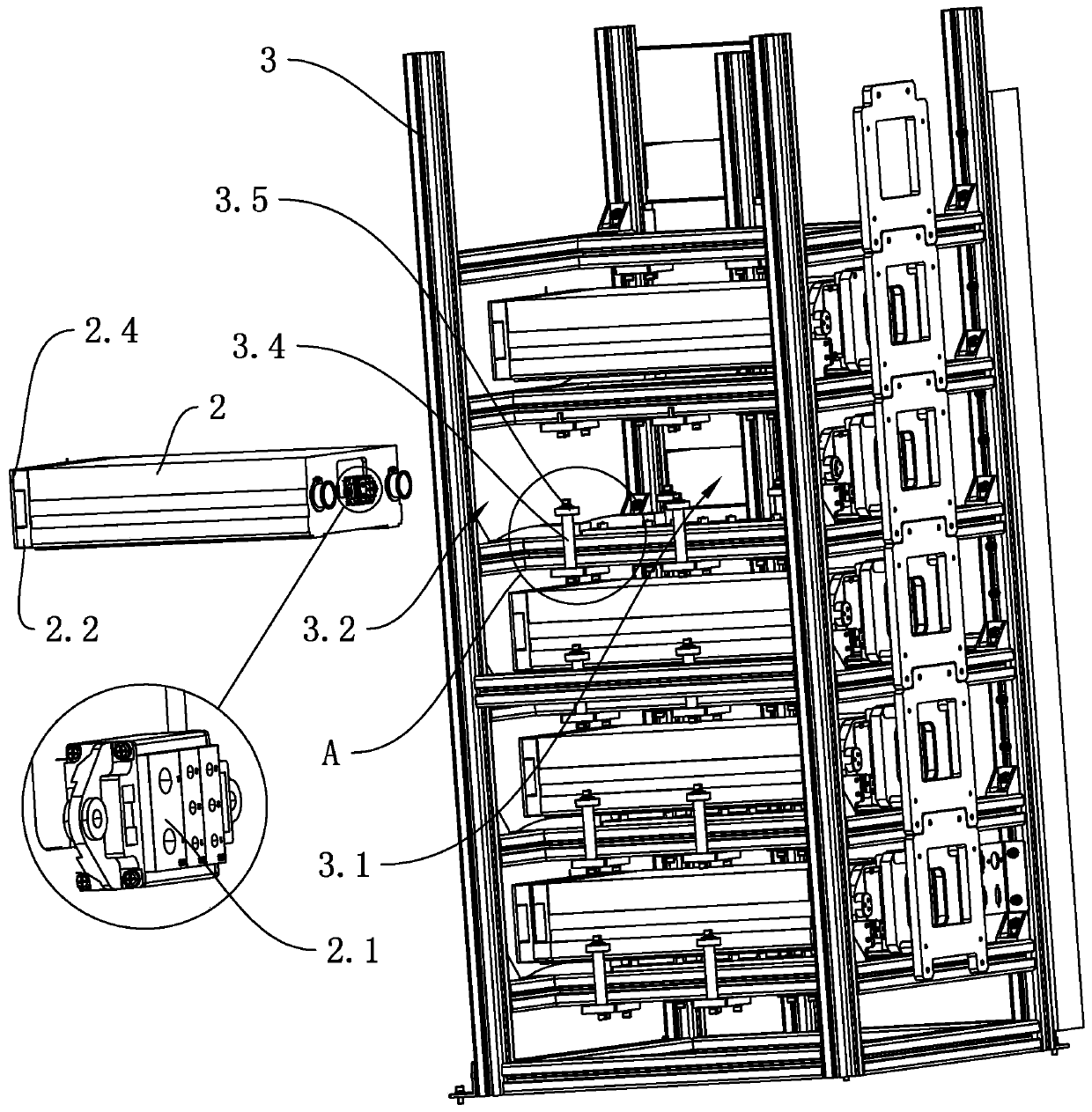

[0056] Embodiment: a kind of AGV charging station, such as figure 1 As shown, the bottom frame 1 is included, and the bottom frame 1 is provided with a load-bearing frame 3 and a battery loading and unloading replacement device 10; the number of bearing frames 3 is two, which are relatively arranged on both sides of the battery loading and unloading replacement device 10. figure 2 Among them, each carrying frame 3 is provided with a plurality of cabins 3.1 in its own height direction, and the shape of the cabins 3.1 is a cuboid, and each cabin 3.1 has an inlet and outlet 3.2, and the inlet and outlet 3.2 face another bearing frame 3 opposite to it, Each compartment 3.1 is correspondingly placed with a storage battery 2 .

[0057] Such as image 3 and Figure 4 As shown, each cabin 3.1 is fixedly installed with installation rods 3.4 extending along the height direction of the bearing frame 3. There are two rows of installation rods 3.4, two in each row, and are distributed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com