Seedling picking mechanism of vegetable transplanting machine

A technology for transplanting machines and vegetables, applied in the field of agricultural and forestry machinery, can solve the problems of high labor intensity, complex movements, low transplanting efficiency, etc., and achieve the effect of reducing labor intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

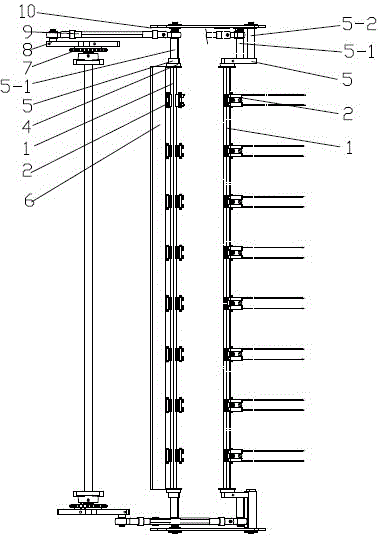

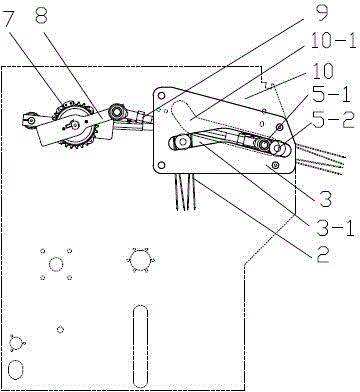

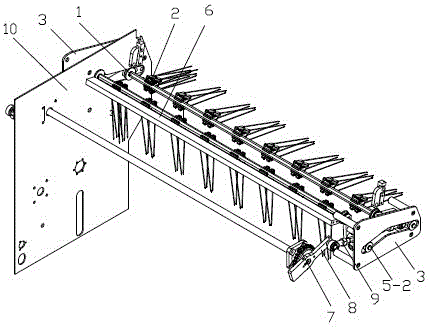

[0022] The seedling picking mechanism of the vegetable transplanting machine of the present embodiment is as follows: figure 1 , 2 , Shown in 3, 4, contain rear end and be fixed on the cross-section and be a group of interval distribution and get seedling clip 2 on the regular hexagonal seedling clip axle 1. The two ends of this seedling clip shaft 1 are respectively equipped with the inner guide groove 3-1 on the inner frame plate 3 (referring to figure 2 ) constitutes the inner bearing 4 of the moving pair, and is fixedly connected with one end of the index bell crank 5 having the first and second extreme positions. The other end of this index crank throw 5 constitutes moving pair by the end pin 5-2 that outer bearing is housed and the outer guide groove 10-1 on the outer frame plate 10. The middle part of the index crank throw 5 is hinged with one end of the connecting rod 9 whose length can be adjusted by means of the screw rod through the middle pin 5-1, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com