Thermal vibrating integrated incremental forming device for magnesium alloy thin-wall part and forming technology thereof

A progressive forming, magnesium alloy technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to control the surface quality of parts, easy to form defects, wear and tear of processing tools, etc., to achieve short process and reduce distortion Effect of springback deformation and wear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

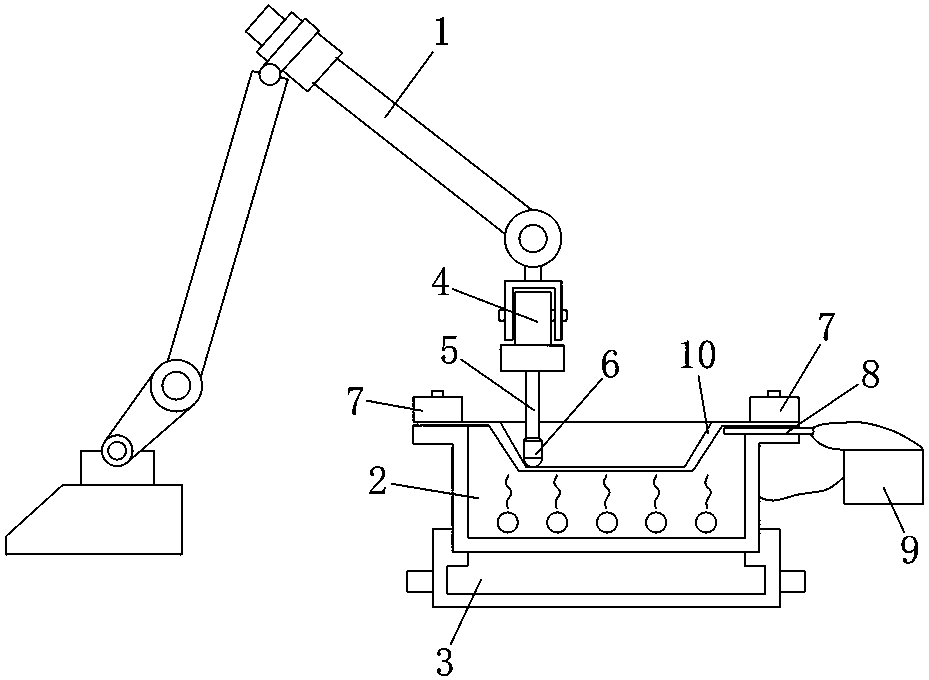

[0023] Such as figure 1 As shown, a thermal-vibration combined progressive forming device for magnesium alloy thin-walled parts of the present invention includes an existing industrial manipulator 1, a heating box 2, a cooling box 3, a vibration generator 4, a horn 5, and a tool head 6 And the blank briquetting 7, the edge of the heating port at the upper end of the heating box 2 is screwed with some blank briquetting 7 for pressing the magnesium alloy thin-walled part 10, and the heating box 2 is used to heat the magnesium alloy thin-walled part 10 to preset temperature; the cooling box 3 is installed at the lower end of the heating box 2 for heat insulation and adjusting the temperature of the heating box at an appropriate time; the vibration generator 4 is installed at the end of the industrial manipulator 1, and the industrial man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com