The secondary locking mechanism of the operating mechanism of the circuit breaker

An operating mechanism and secondary lock technology, applied in the protection switch operation/release mechanism, circuits, electrical components, etc., can solve the problems of slow tripping speed and slow response speed of the operating mechanism, and reduce the requirements of manual operation force and reduce The effect of tangential friction and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

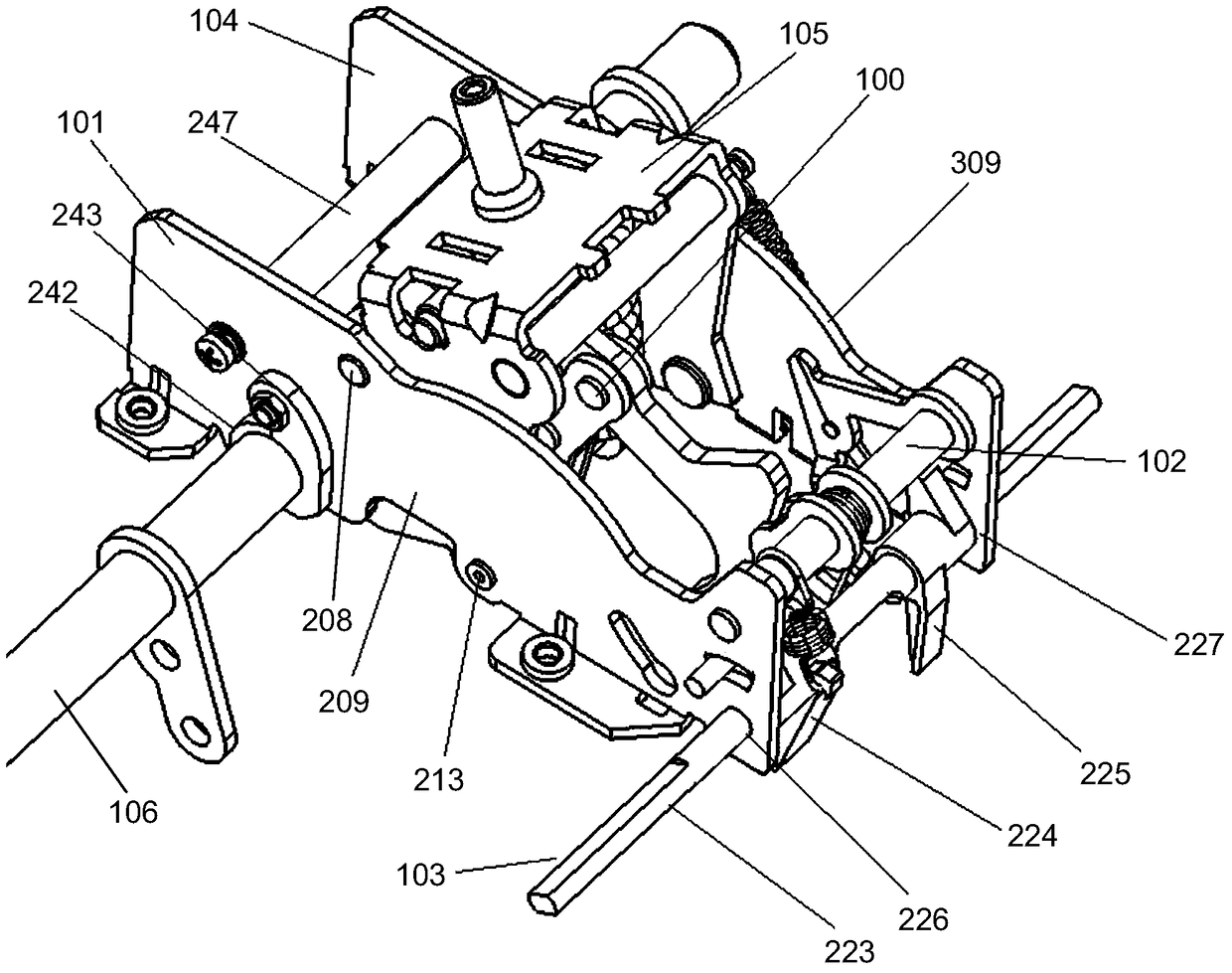

[0028] refer to figure 1 as shown, figure 1 A structural diagram of an operating mechanism of a circuit breaker adopting the secondary locking mechanism of the present invention is disclosed. The operating mechanism 107 includes a jumper assembly 100 , a left plate assembly 101 , a lock assembly 102 , a half shaft assembly 103 , a right plate assembly 104 , a lever assembly 105 and a spindle assembly 106 .

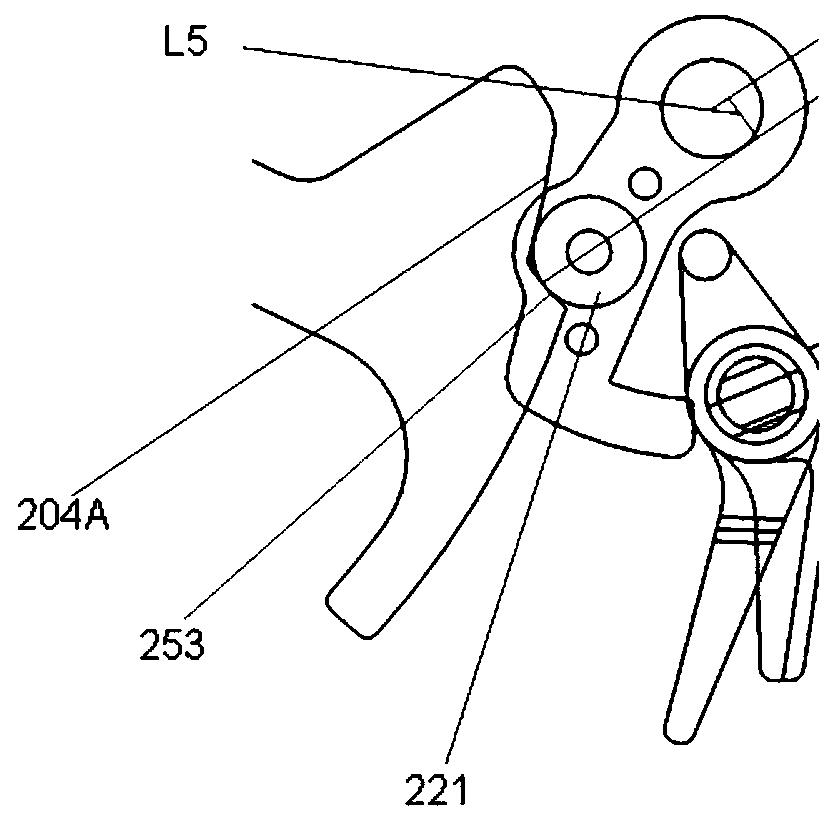

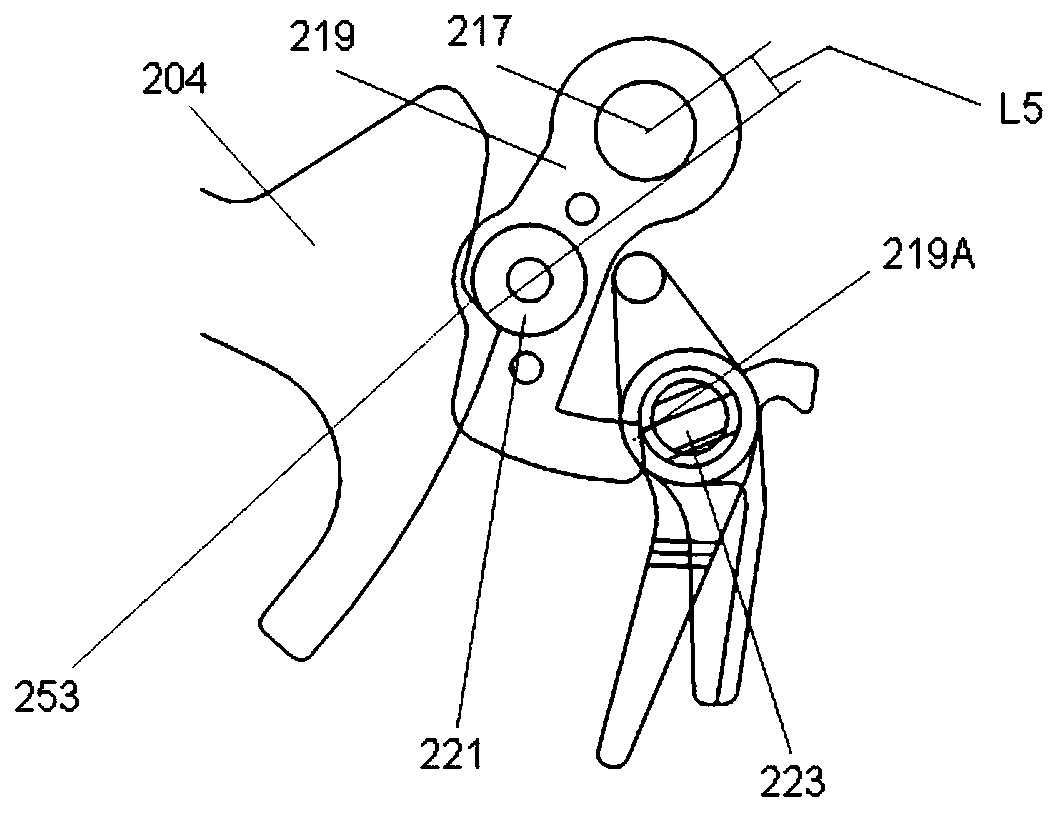

[0029] Figure 2a and Figure 2b A structural diagram of the jumper assembly is revealed. refer to Figure 2a and Figure 2b As shown, the jumper assembly 100 includes a jumper 204 . The first end of the jumper 204 has a first hole 207 , and the rotating shaft 208 is riveted in the first hole 207 . The middle part of the jumper 204 has a pin hole, and the pin 203 passes through the pin hole, and the upper link 201 is riveted on the jumper 204 . There is a limit hole near the hole of the pin shaft, and the limit pin 205 is riveted in the limit hole. because Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com