Panel type metal rubber vibration rolling compound forming equipment

A metal-rubber and composite molding technology, which is applied in the field of flat metal-rubber vibration-rolling composite molding equipment, can solve problems such as affecting product performance stability, uneven plastic deformation, and shortening mold life, so as to improve comprehensive mechanical properties, reduce The effect of forming force and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

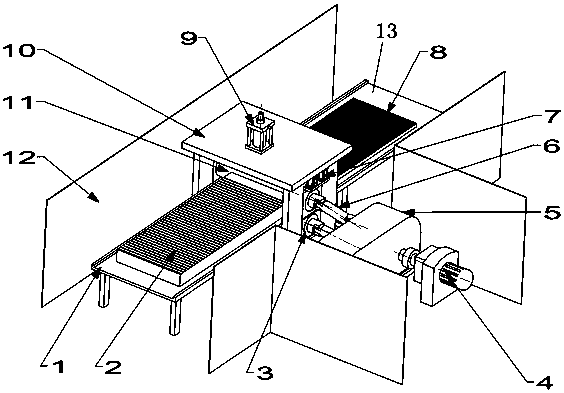

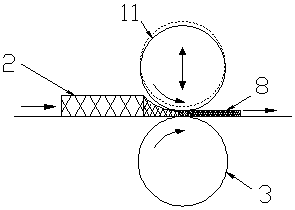

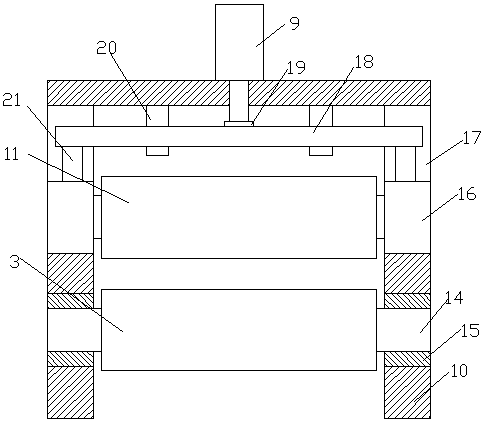

[0020] Such as Figure 1-3 As shown, a flat metal-rubber vibratory rolling compound molding equipment includes a frame 10, the upper part of the frame 10 is provided with an upper roller 11, a lower roller 3 from top to bottom, an upper roller 11, a lower roller From the gap between the wheels 3 that is conducive to the passage of materials, the shaft parts 14 at both ends of the lower roller 3 are rotatably connected to the frame 10 through the bearing seat 15, and the two ends of the lower roller 3 are rotatably connected to the slider 6 through the bearing seat 15. The block 6 is installed on the frame 10 and can move up and down relative to the frame 10. The top of the frame 10 is provided with an exciter that drives two slide blocks 6 to reciprocate vertically. Material conveyor belt 1, discharge conveyor belt 13, motor 4 and speed reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com