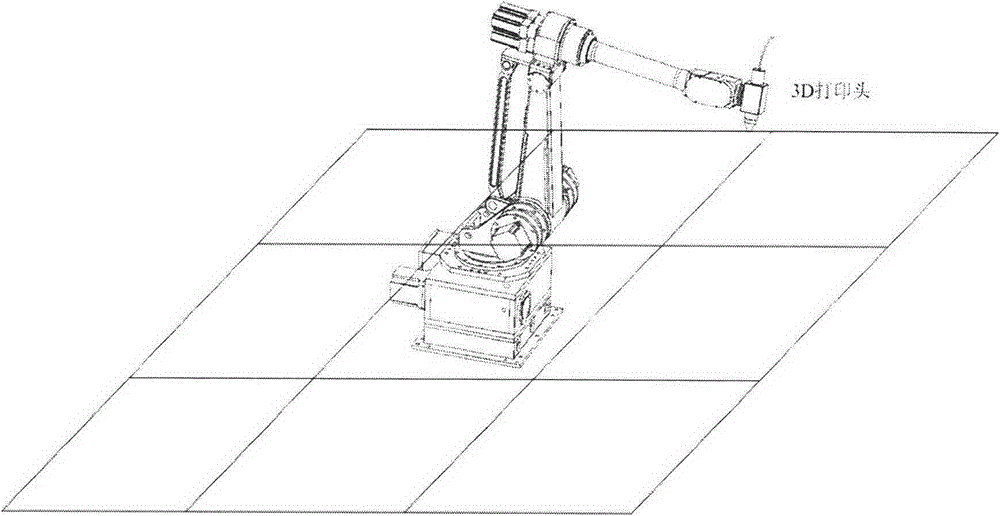

3D printing robot based on industry manipulator

A technology of industrial manipulators and industrial robots, applied in manipulators, manufacturing tools, etc., can solve the problems of slow printing speed, inability to install the print head, free printing, etc., and achieve the effect of expanding the printing space and printing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

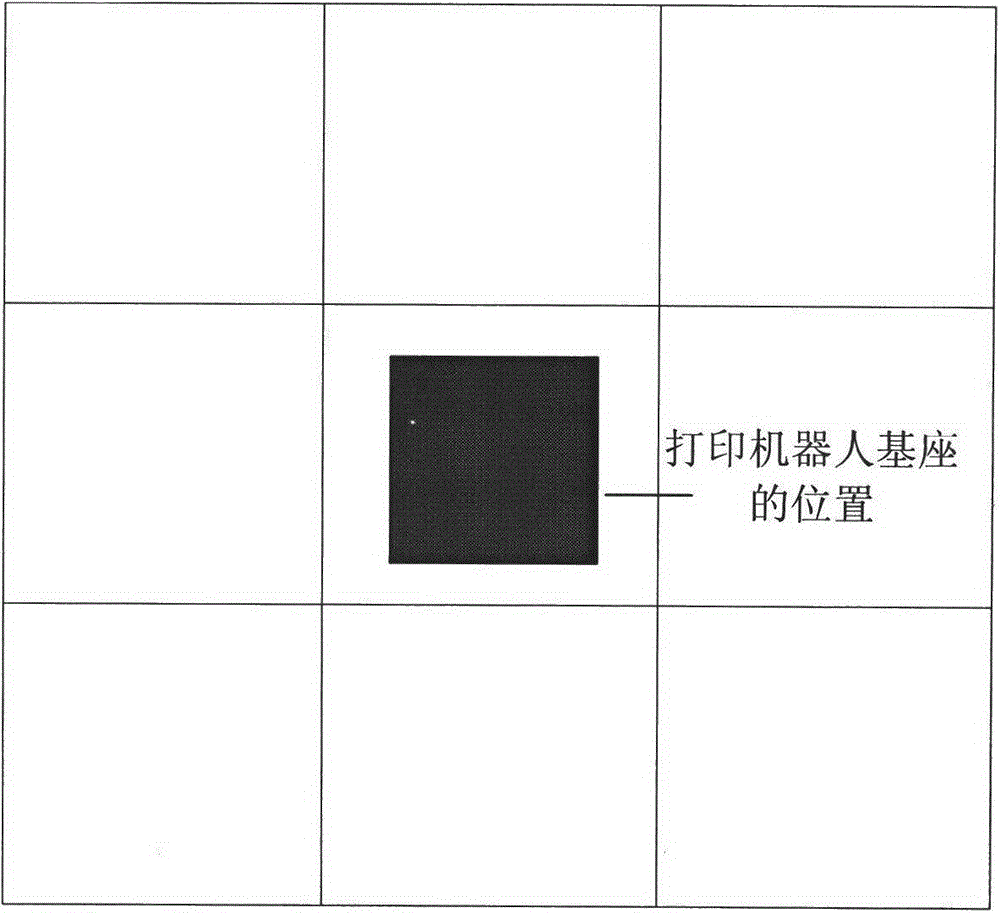

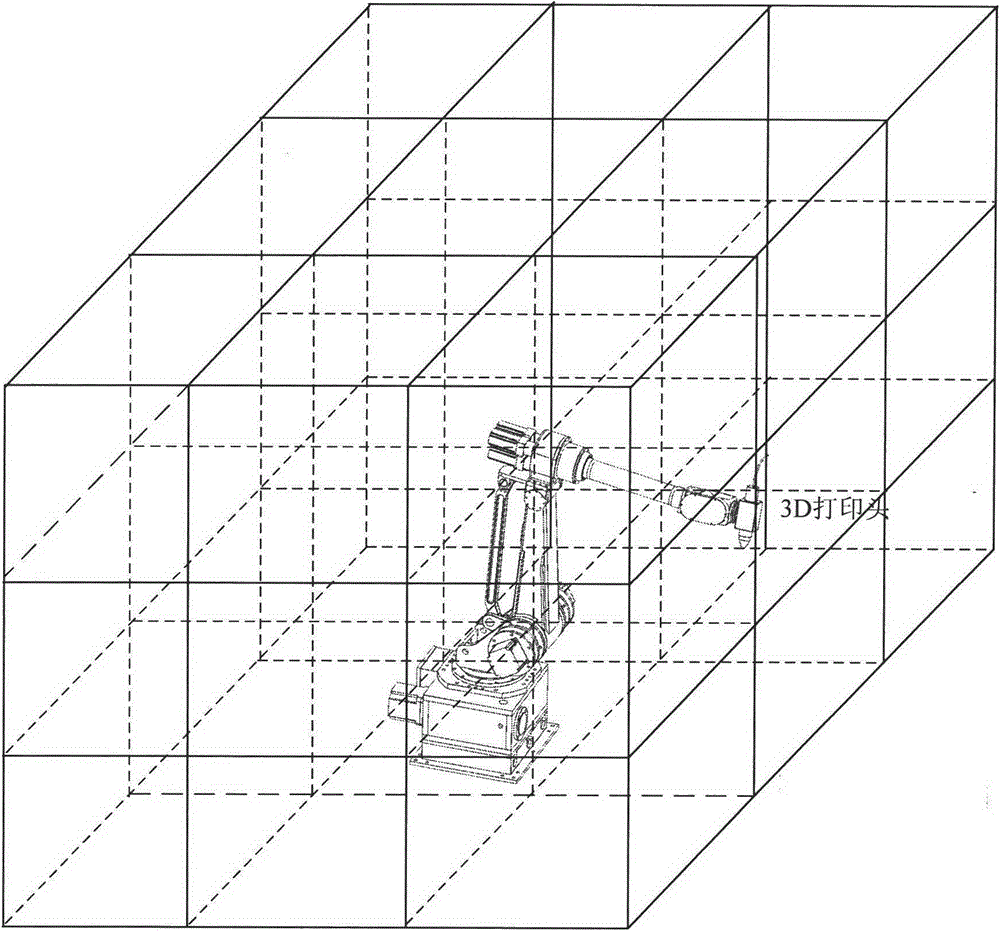

[0010] 1. System initialization, reposition the base of the printing robot.

[0011] 2. The computer loads the 3D drawing and starts the printing task.

[0012] 3. When printing large objects, the system can automatically lay guide rails, print space by space, and perform automatic fusion.

[0013] 4. When the printing material is lower than the lower limit of the material capacity, the system will automatically prompt that the material is insufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com