Industry-manipulator-based in-pipe polishing system of stainless steel elbow pipe

An industrial manipulator and internal polishing technology, applied in manipulators, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of low work efficiency, difficult polishing, and high cost, and achieve simple control, reliable clamping, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

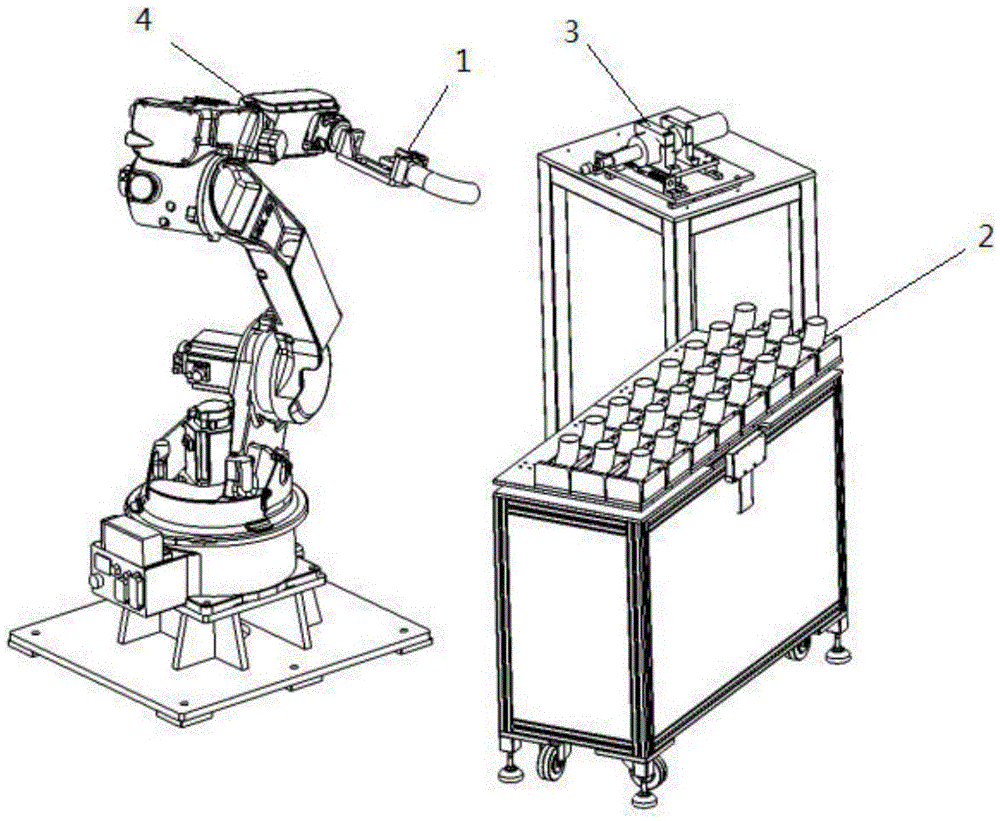

[0038] Such as Figure 1-6 As shown, the present invention provides an industrial manipulator-based stainless steel elbow in-pipe polishing system, including an industrial manipulator 4 , a clamping mechanism 1 , a loading vehicle 2 and an in-pipe polishing mechanism 3 . The clamping mechanism 1 is installed at the end of the industrial manipulator 4, and the industrial manipulator 4 grabs and clamps the stainless steel elbow 131 from the loading car 2 through the clamping mechanism 1; then sends the stainless steel elbow 131 to the inner polishing mechanism 3 The polishing station performs in-pipe polishing.

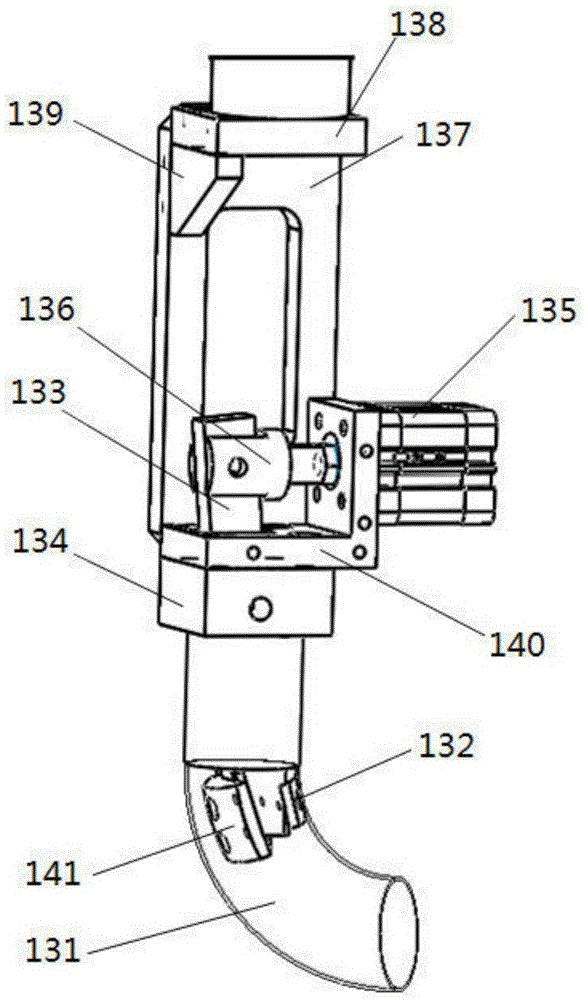

[0039]The clamping mechanism 1 includes a mechanical support unit and a clamping action unit.

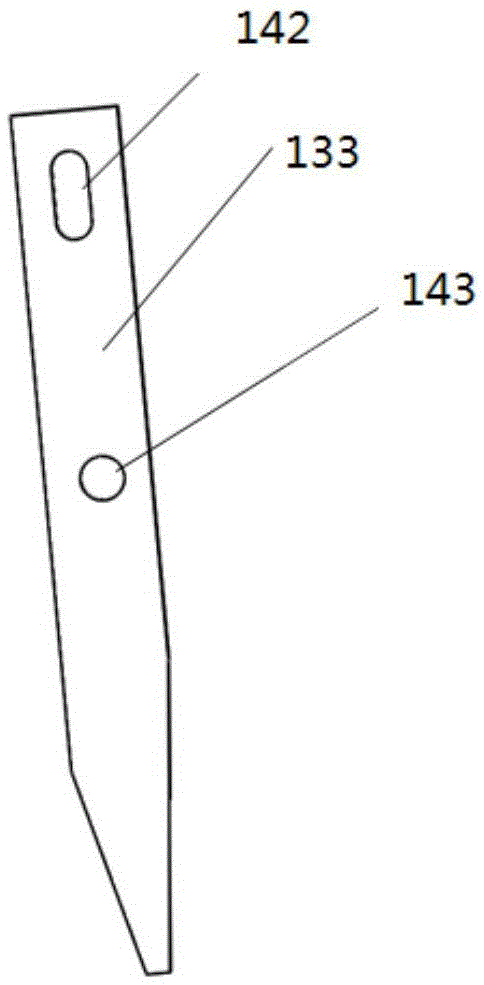

[0040] The mechanical support unit includes a manipulator connecting piece 138 , a reinforcing rib 139 , a main connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com