Automatic locking and disassembling device for work piece clamping and locking nut of gear manufacturing equipment

A technology for workpiece clamping and locking nuts, which is applied to gear tooth manufacturing devices, mechanical equipment, manufacturing tools, etc., can solve the problems of poor working environment, low efficiency, and high labor costs for workers, achieve low cost, improve efficiency, and reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

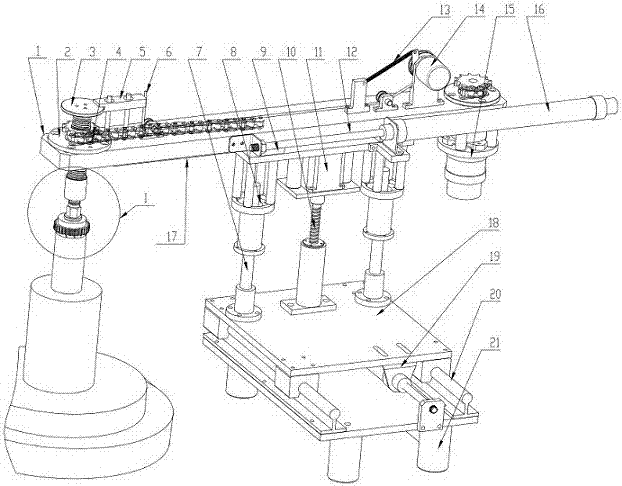

[0016] as attached figure 1 , Shown in 2, the device consists of a mechanical arm, a rotary transmission mechanism, a sleeve spring mechanism, a sleeve displacement sensor, a cartridge nut and a control circuit.

[0017] The mechanical arm includes X-axis slide plate 1, Z-axis guide rod 7, Z-axis slider mechanism 8, X-axis slider 9, Z-axis screw mechanism 10, Z-axis motor 11, X-axis cylinder push rod 12, X-axis To the push-pull cylinder 16, the X-axis slide rail 17, the Y-axis slide plate mechanism 18, the Y-axis push-pull cylinder 19, the Y-axis slide rail 20 and the height adjustment pad cover 21.

[0018] Rotary transmission mechanism is made up of hexagonal sprocket sleeve bearing block 2, power chain 4, motor 15 and sprocket wheel.

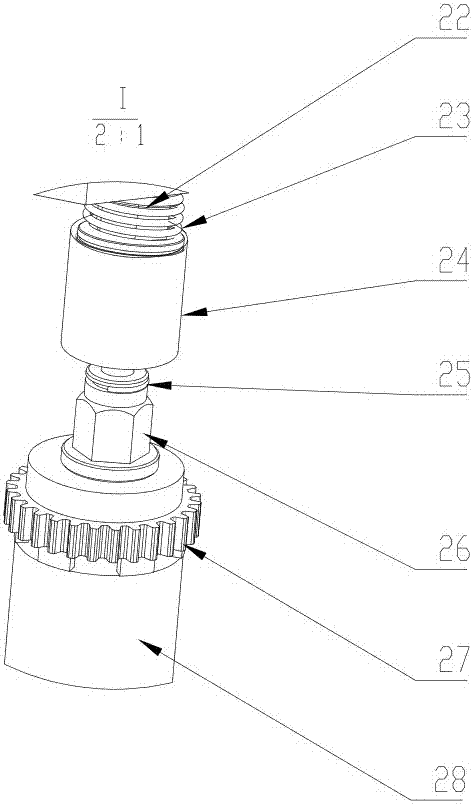

[0019] The sleeve spring mechanism includes a floating hexagonal shaft 22 , a floating return spring 23 and a sleeve 24 . Wherein, there is a groove in the sleeve to cooperate with the clip spring of the clip nut.

[0020] The sleeve displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com