Automatic assembling system based on three-dimensional vision

An automatic assembly and three-dimensional vision technology, applied in the system field of parts assembly, can solve problems such as high system hardware requirements, increase modification costs, increase load, etc., achieve the effect of reducing debugging time, lowering the threshold of use, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

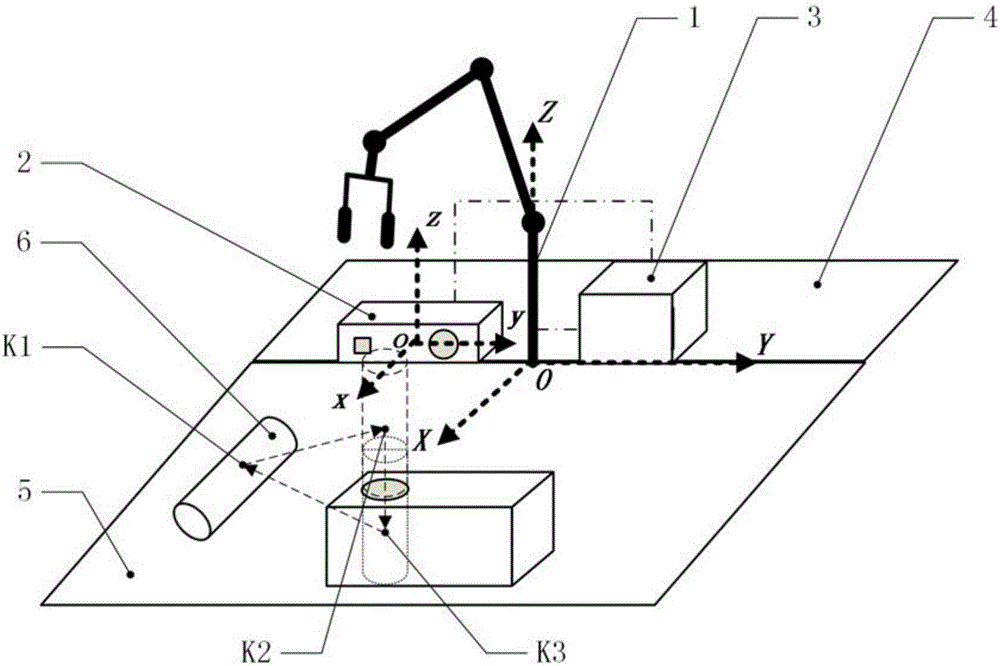

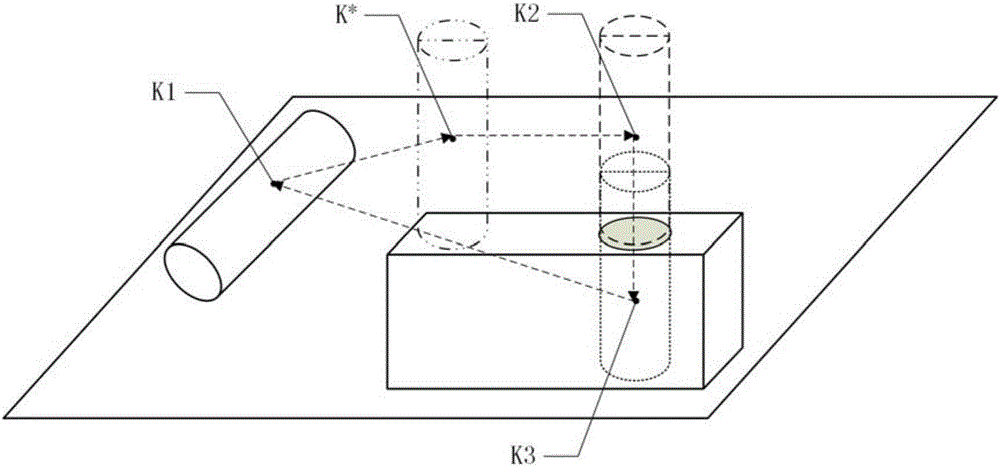

[0028] Such as figure 1 As shown, the automatic assembly system based on three-dimensional vision includes a frame 4, an industrial manipulator 1 fixedly installed on the frame 4, a manipulator controller 3 and a three-dimensional camera 2; the three-dimensional camera 2 obtains the two-dimensional Image and depth information, the industrial manipulator 1 completes the automatic assembly task according to the teaching process after the teaching training. During the teaching process, the workpiece is held by the human hand to complete the migration of the workpiece from the original pose, the initial assembly pose and the assembly end pose ;

[0029] Teaching training includes:

[0030] S1. Calibrate the manipulator coordinate system OXYZ and the three-dimensional camera coordinate system oxyz, and calculate the conversion matrix from the three-dimensional camera coordinate system oxyz to the industrial manipulator coordinate system OXYZ;

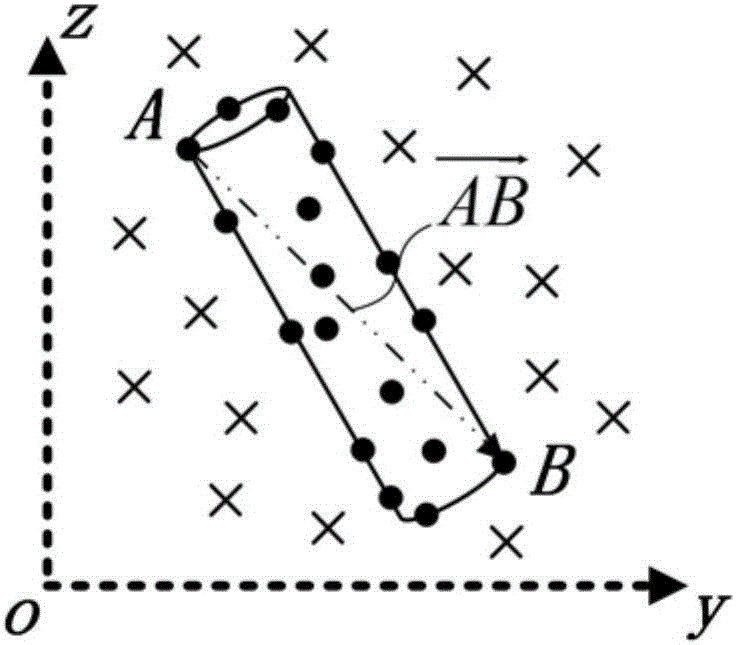

[0031] S2. The three-dimensional ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com