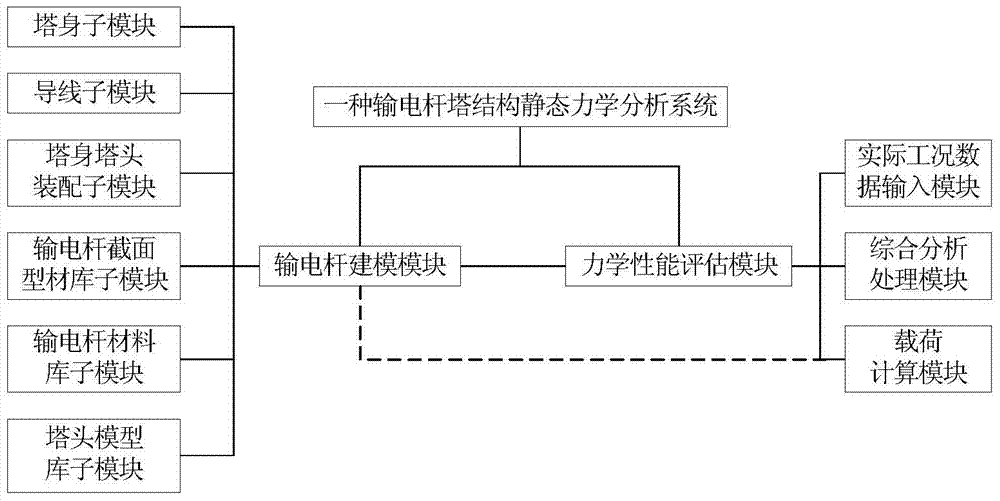

System and simulation method for transmission tower structure static mechanic analysis

A transmission tower and analysis system technology, applied in the field of electric power industry, can solve the problems of complex modeling and analysis process of tower structure, long cost cycle, high cost, etc., achieve standard tower modeling process and performance evaluation process, improve efficiency and quality , the effect of lowering the threshold of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

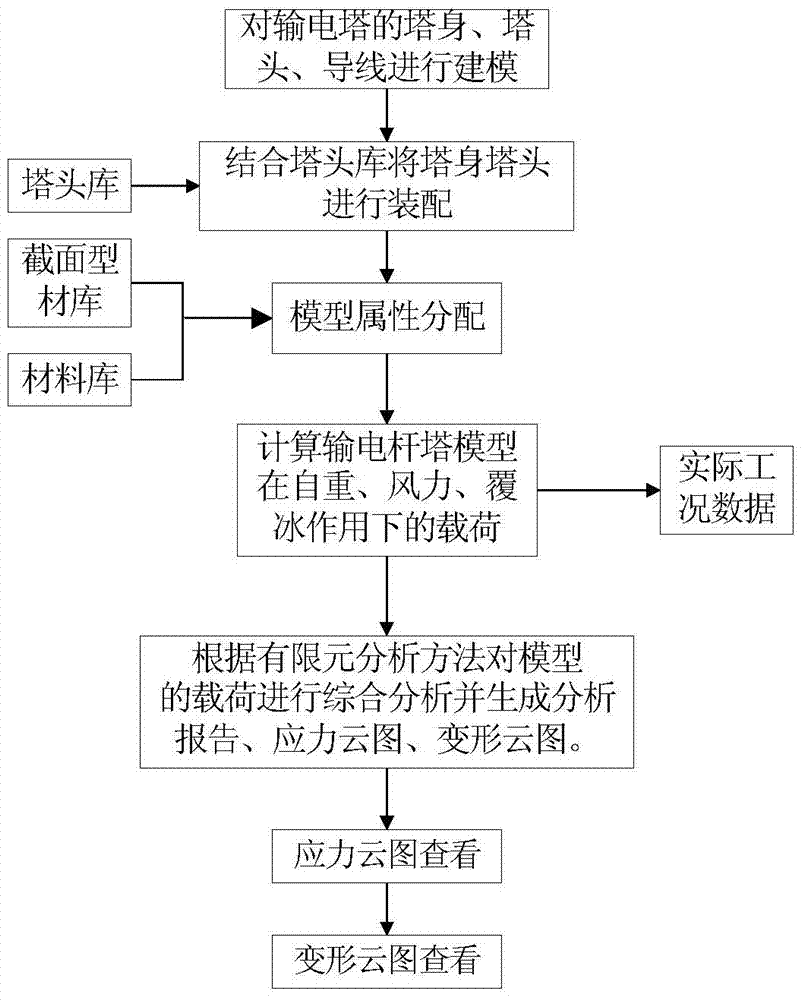

[0044] In this case, a three-tower and four-line model including a load-bearing tower and tension towers at both ends is selected for static analysis. The specific steps are as follows:

[0045] (1) Build the tower body model

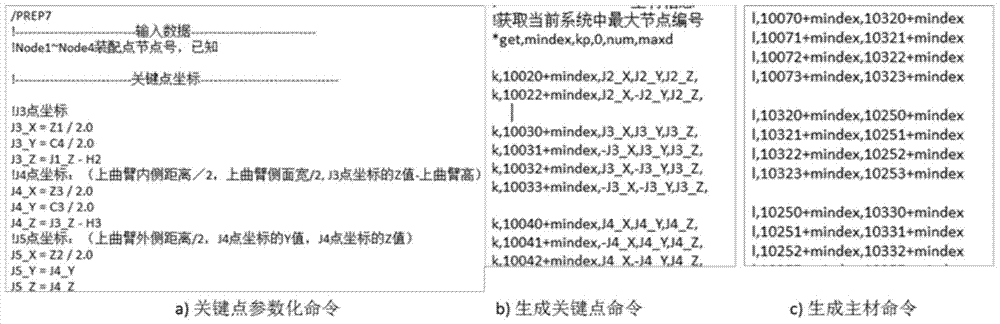

[0046] First, build the body model of the middle tower. Using the interface developed by the system, input the node numbers and node coordinates in sequence (1, -2.2, 2.2, 26.9; 2, -2.59, 2.59, 31.4; 3, -2.83, 2.83, 34.2; 4, -3.07, 3.07, 37.0 ;...), using Ans y s software function to generate Ke y Point, by connecting Key Point forms the rod Line, and finally generates the middle tower body model.

[0047] Secondly, establish the tower body model at both ends. Use the tower body modeling interface at both ends of the system to input the node number and node coordinates (66, -1.7, -41.7, 28.0; 67, -1.9, -41.9, 31.0; 71, -2.2, -42.2, 33.9; ...) connect to generate members. The tower body models at both ends are generated by the position of the tower...

example 1

[0054] Example 1: For model D91420, the last two digits represent the thickness of the steel pipe; the first two / three digits represent the outer diameter of the steel pipe. D—seamless steel pipe; 914—outer diameter of steel pipe, 914mm; 20—thickness of steel pipe, 20mm.

example 2

[0055] Example 2: For model L5004, the last two digits represent the thickness of the angle steel; the first two / three digits represent the length of the angle steel. L—equal side angle steel; 50—angle steel length, 50mm; 04—angle steel thickness, 4mm.

[0056] First define the material of the tower body, and select Q345 steel for the tower body; secondly, define the cross-sectional shape of the tower body, use equilateral angle steel L20024 for the stressed parts, and use equilateral angle steel L8010 for auxiliary parts.

[0057] (4) Establish wire model

[0058] The insulators and other components are ignored in the modeling of this model, and the wires are directly connected to the cross-arm of the tower. Four conductors are connected to each tower head.

[0059] (5) Define wire properties Consider the twisting deformation of the wire, use ansysBeam189 beam element. The section is defined as a solid circular section with a diameter d=32.76mm and a cross-sectional area A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com