Remote monitoring and control system for industrial manipulator based on Internet

An industrial manipulator and internet technology, applied in the field of industrial manipulator remote monitoring and control system, can solve the problems of industrial manipulator action error, damage to manipulator or matching equipment, incomplete information interaction and recording functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

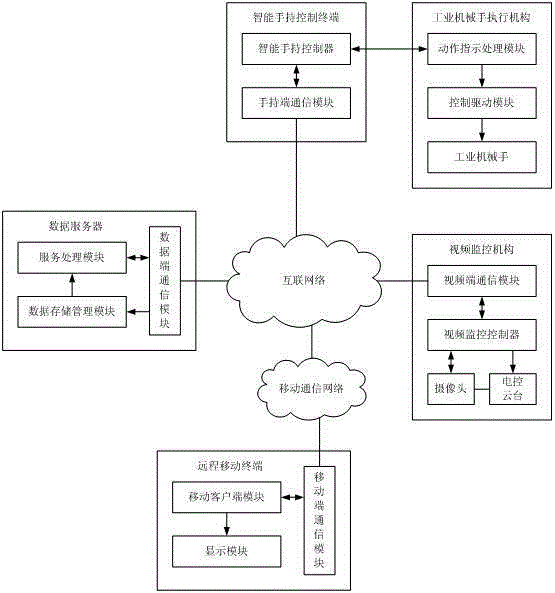

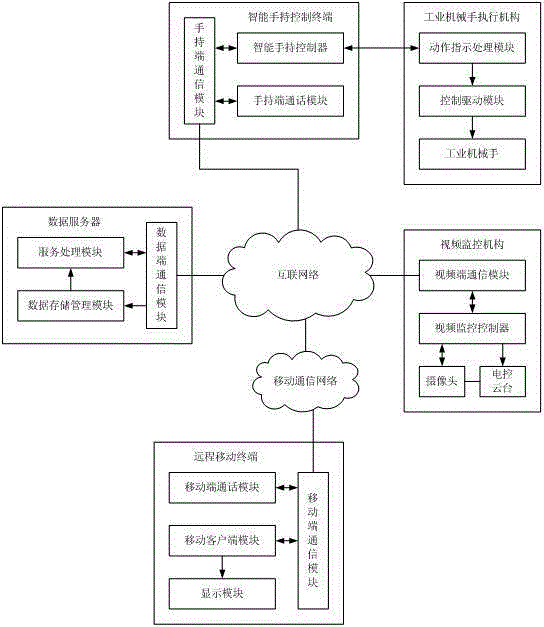

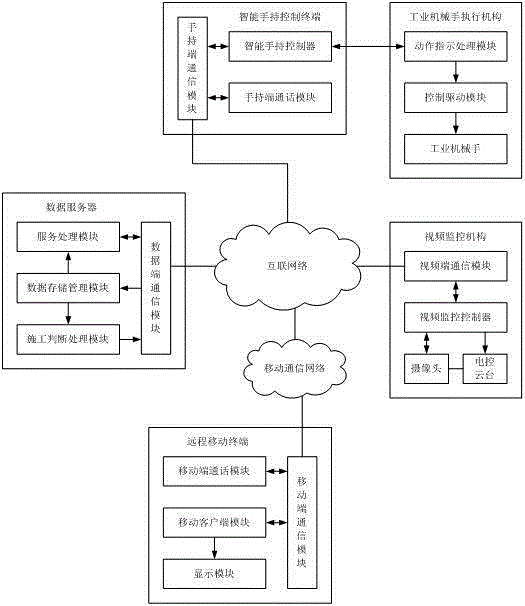

[0028] The invention provides a remote monitoring and control system for industrial manipulators based on Internet, such as figure 1 As shown, the industrial manipulator remote monitoring and control system includes an industrial manipulator actuator, an intelligent handheld control terminal, a video monitoring mechanism, a data server and a remote mobile terminal.

[0029] The industrial manipulator actuator is installed on the processing and construction site, including the industrial manipulator, the control drive module and the action instruction processing module; the industrial manipulator is used to execute the construction action according to the driving of the control drive module; the control drive module is used to process the manipulator according to the action instruction processing module Action control instructions, which control and drive the construction actions of industrial manipulators; the action instruction processing module communicates with the smart han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com