Increment forming device and method for performing increment forming by utilizing increment forming device

A technology of incremental forming and heating forming, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor forming accuracy and achieve the effects of reduced deformation resistance, good surface quality, and coordinated motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

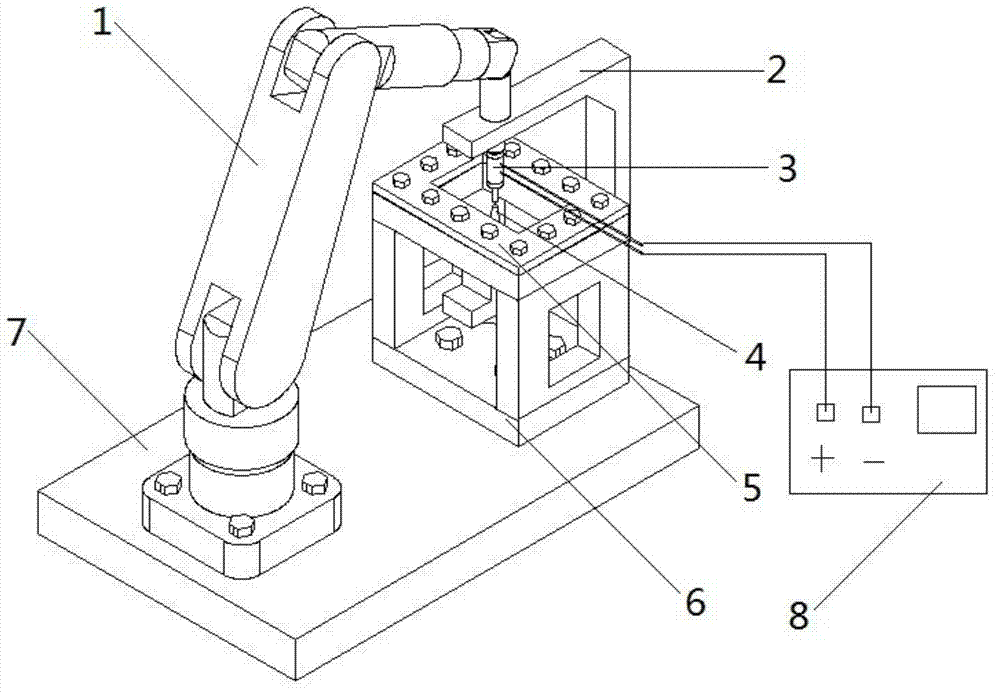

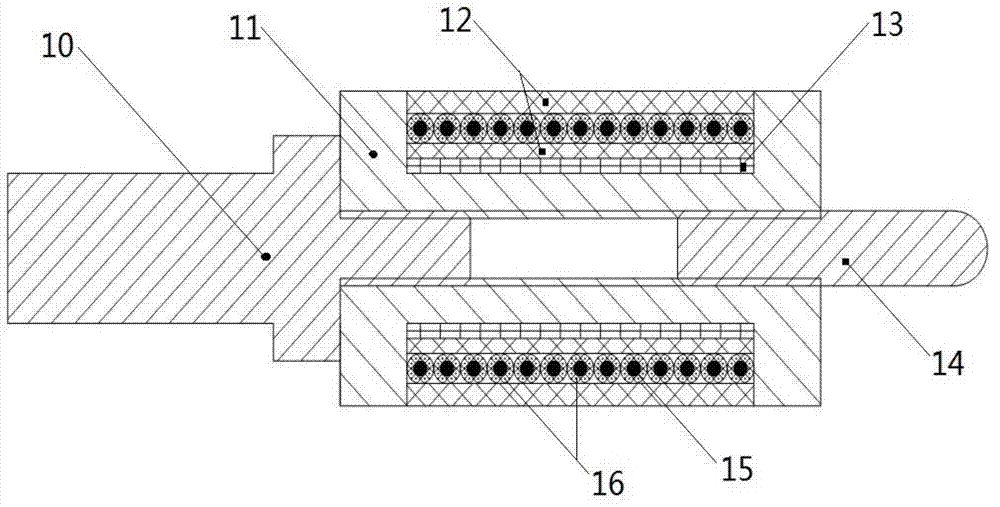

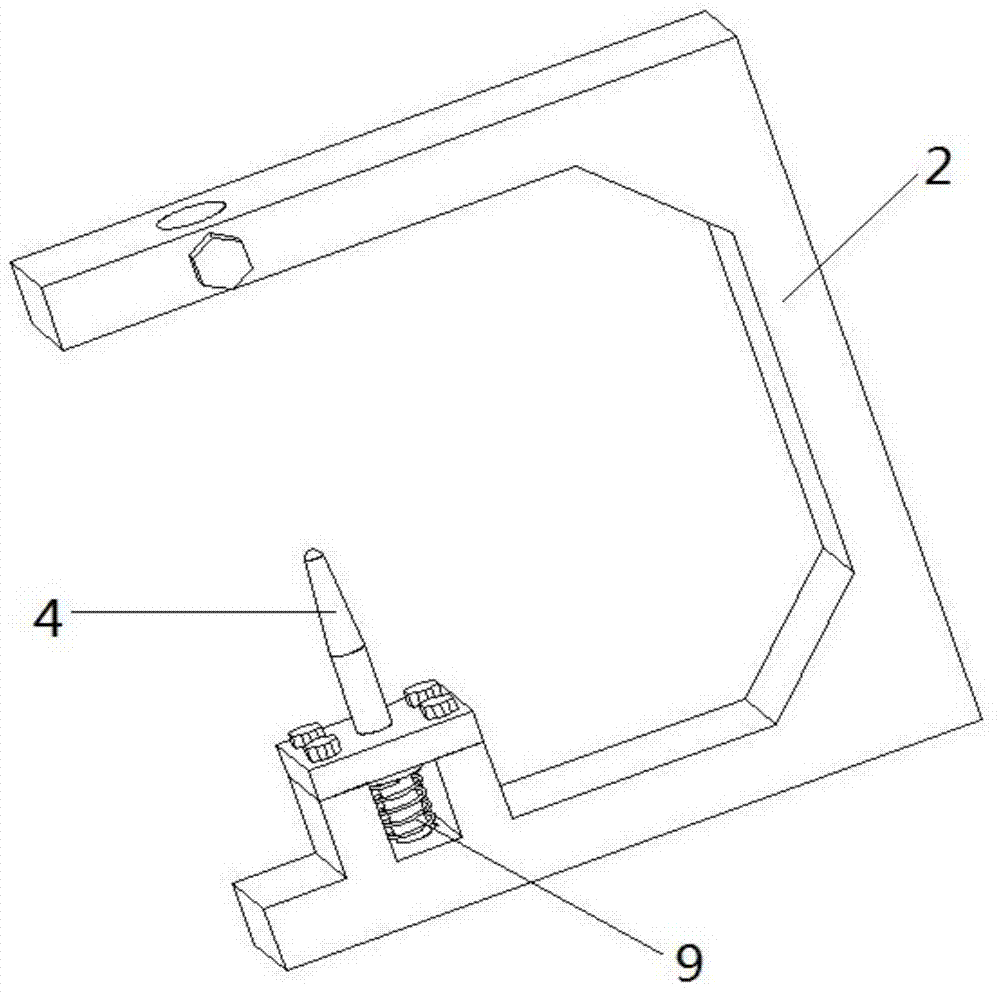

[0027] refer to figure 1 -6. This embodiment is used for the incremental forming of a 2024 aluminum alloy sheet with a size of 400mm×300mm and a thickness of 1mm. The electromagnetic induction heating incremental forming device includes an industrial robot arm 1, a C-shaped frame 2, a heating forming head 3, an extrusion tool head 4, a pressing plate 5, a clamping frame 6, a base 7, a power supply 8 and a compression spring 9.

[0028] The clamping frame 6 is installed on one end of the base 7, the bottom surface of the clamping frame 6 is attached to the upper surface of the base 7, fastened by bolts, the industrial robot hand 1 is installed on the other end of the base 7, and the industrial robot hand 1 The bottom surface of the base is attached to the upper surface of the base 7 and fastened by bolts. The pressure plate 5 is located above the clamping frame 6. The bottom surface of the pressure plate 5 is parallel to the upper surface of the clamping frame 6. It is fasten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com