Intermittent ear line welding equipment for mask production

A welding equipment, intermittent technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of restricting production efficiency, reduce the difficulty of debugging, reduce the error, and improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

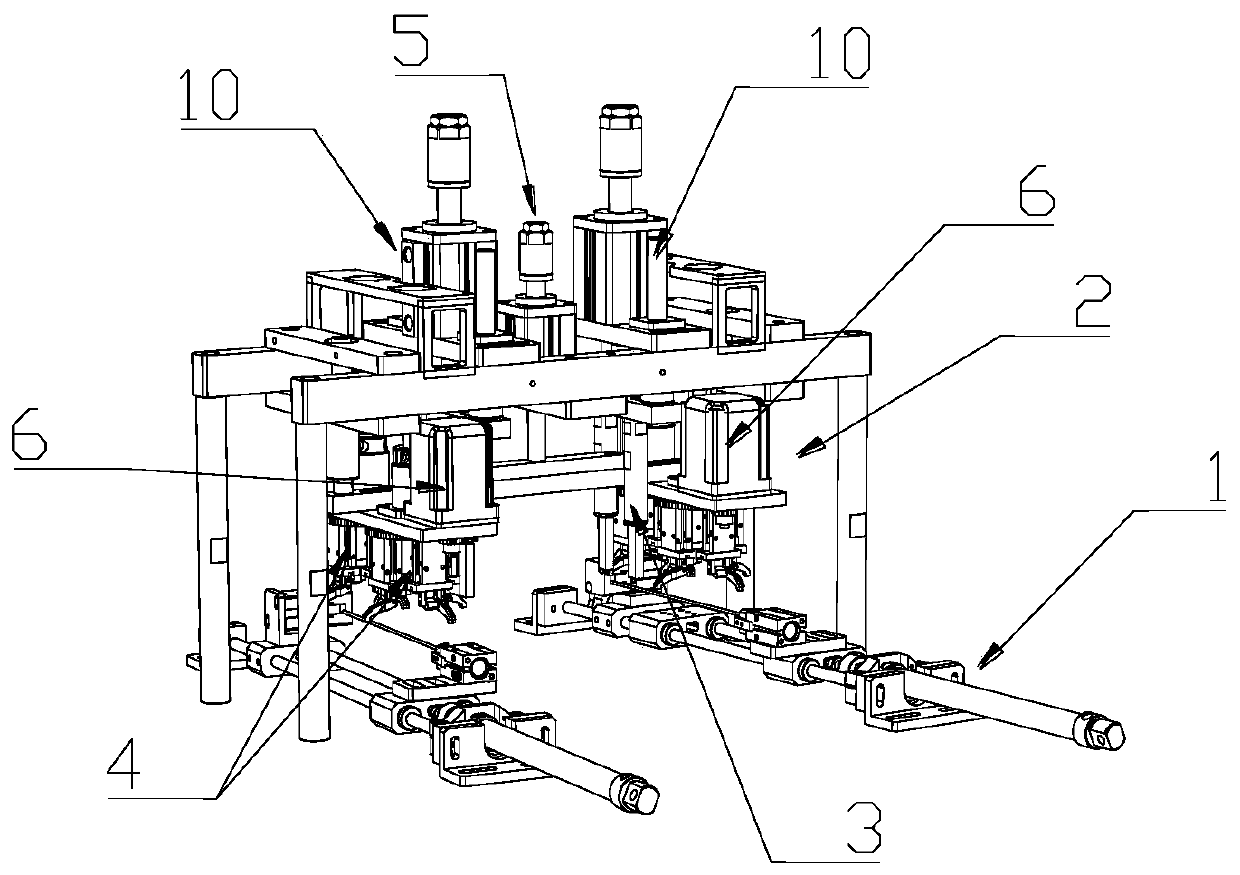

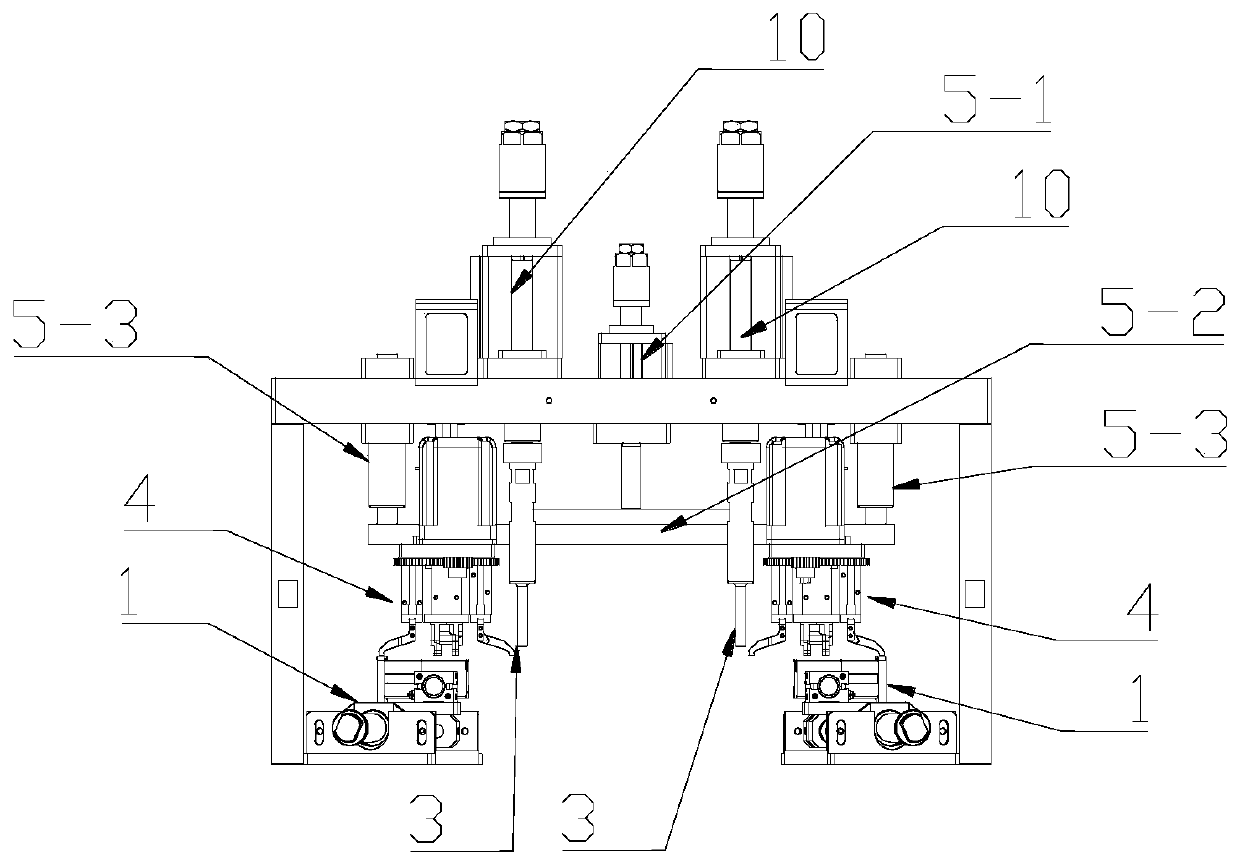

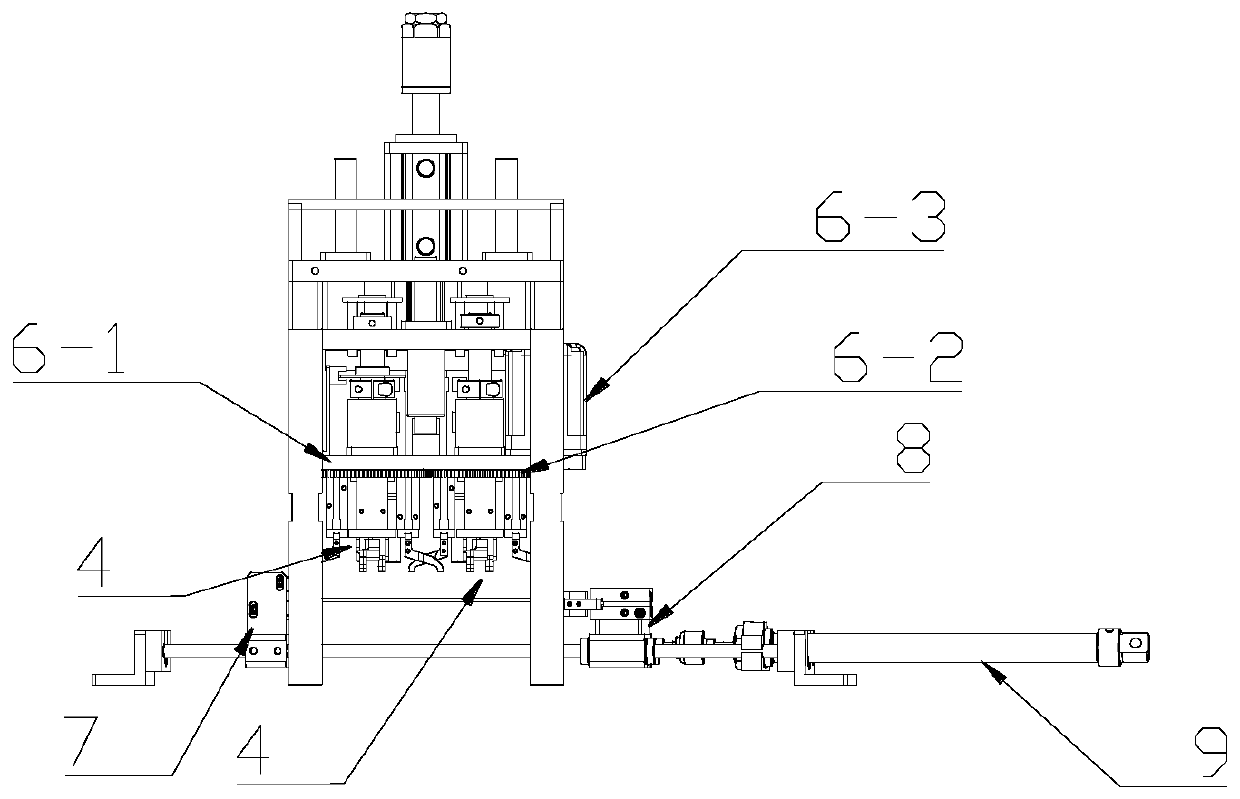

[0032] see Figure 1-Figure 12The intermittent ear wire welding equipment produced by the mask of the present invention comprises a frame, a mask conveying device for conveying masks arranged on the frame, an ear wire conveying device 1 for conveying ear wires, and an ear wire conveying device 1 for conveying ear wires. The ear wire in the device 1 is clamped and transported to the ear wire clamping and conveying device 2 of the ear wire welding station and the ear wire welding device 3 for welding the ear wire at the ear wire welding station to the mask body, wherein ,

[0033] The ear wire clamping and conveying device 2 includes a clamping module 4, a vertical drive mechanism 5 for driving the clamping module 4 to move vertically, and a rotary drive for driving the clamping module 4 to rotate Mechanism 6, wherein, described clamping module 4 is two groups, and is arranged successively along the delivery direction of described mask body; Every group of clamping module 4 com...

Embodiment 2

[0048] The mask production line of the present invention includes intermittent ear wire welding equipment for the mask production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com