Gear form-grinding mechanism

A gear forming and grinding technology, which is applied to the parts of grinding machine tools, gear cutting machines, gear tooth manufacturing devices, etc., can solve the problems of instable grinding wheel dressing accuracy, affecting the grinding accuracy of tooth surfaces, and increasing idle travel of machine tools. To achieve the effect of convenient dressing, high processing efficiency, and small machine tool idle travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in combination with specific embodiments.

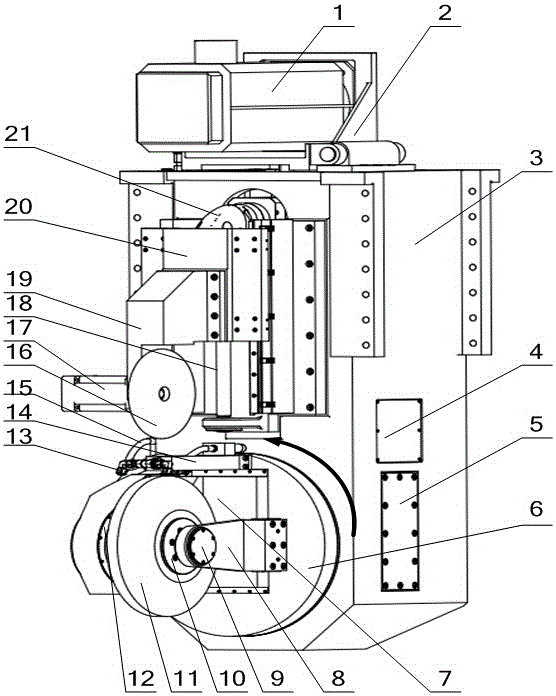

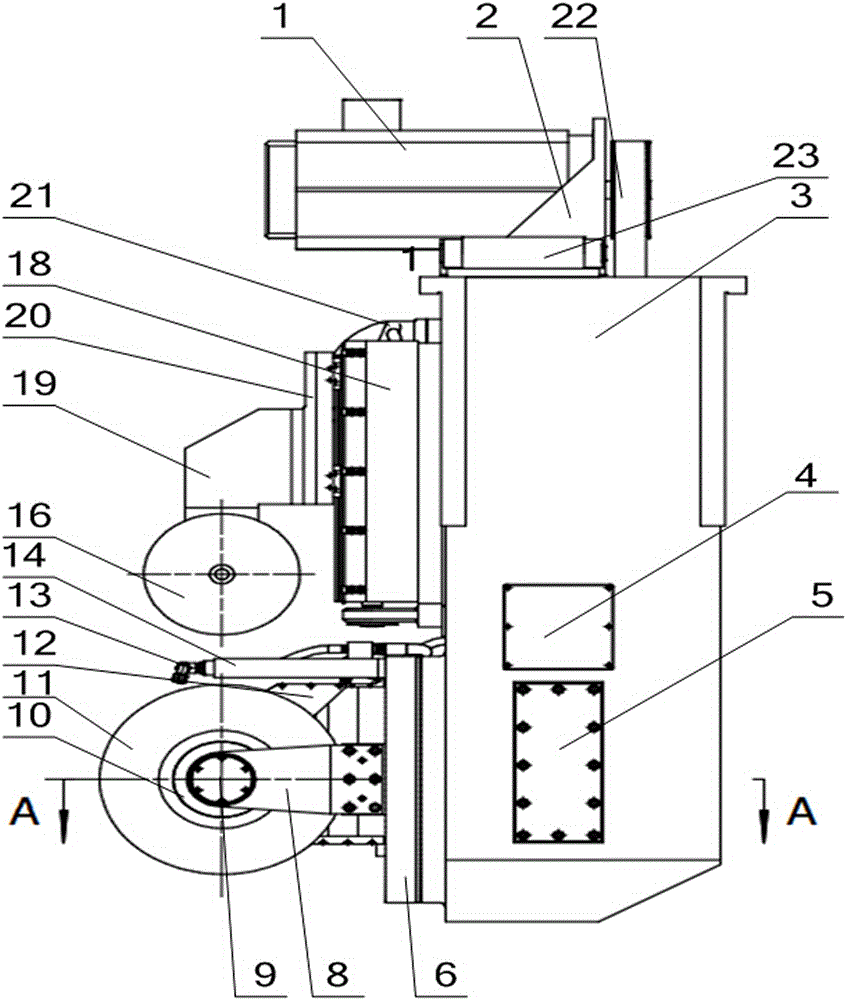

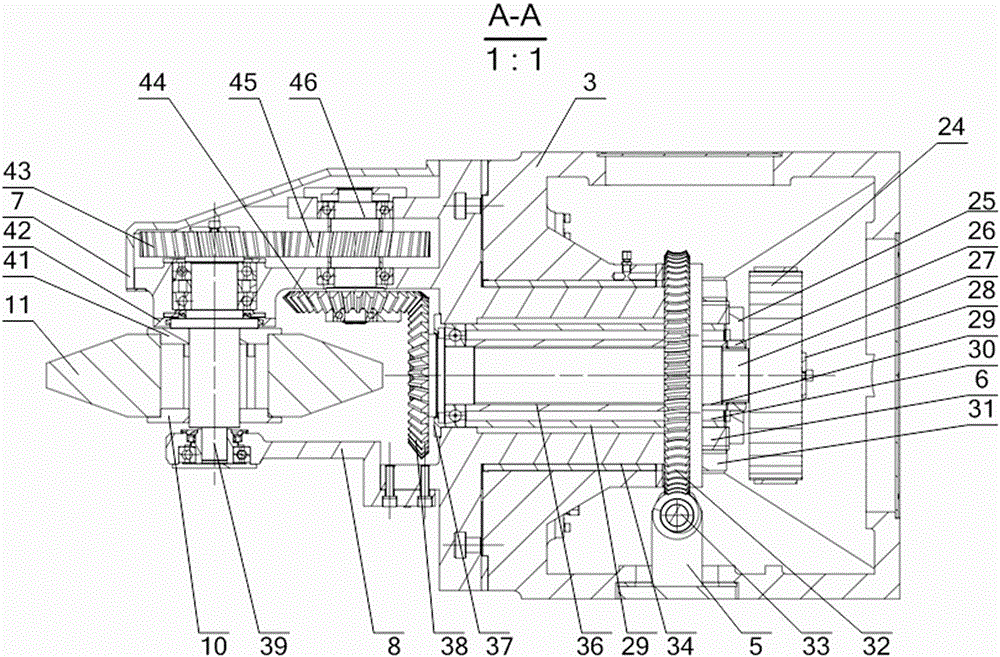

[0022] As shown in the figure: a gear forming grinding mechanism, including a box body 3, a main motor 1, a grinding part, a rotating part, a grinding wheel modification part and a cooling part. Power is provided, and the rotating parts, grinding wheel modification parts and cooling parts are all installed on the box body 3, and the transmission part of the grinding part passes through the box body 3 and is installed inside the box body 3, and the grinding head of the grinding part Installed on the top of the rotary part to drive the parts to be ground to rotate and grind through the rotary part. The cooling parts described above include a coolant nozzle 13, a nozzle bracket 14 and an oil pipe 15, the oil pipe 15 is fixed on the rotating part, the coolant nozzle 13 is installed on the rotating head body 6; the grinding wheel modification part is installed on the box body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com