Sheet metal rigid link structure

A connecting rod structure and diamond-like technology, applied in the direction of electrical components, electric switches, contact operating parts, etc., can solve the problems of keyboard production, complex assembly process, low efficiency of keyboard assembly process, small plastic connecting rod structure, etc., to achieve The material is green and environmentally friendly, there is no inspection process cost, and the effect of less molding steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

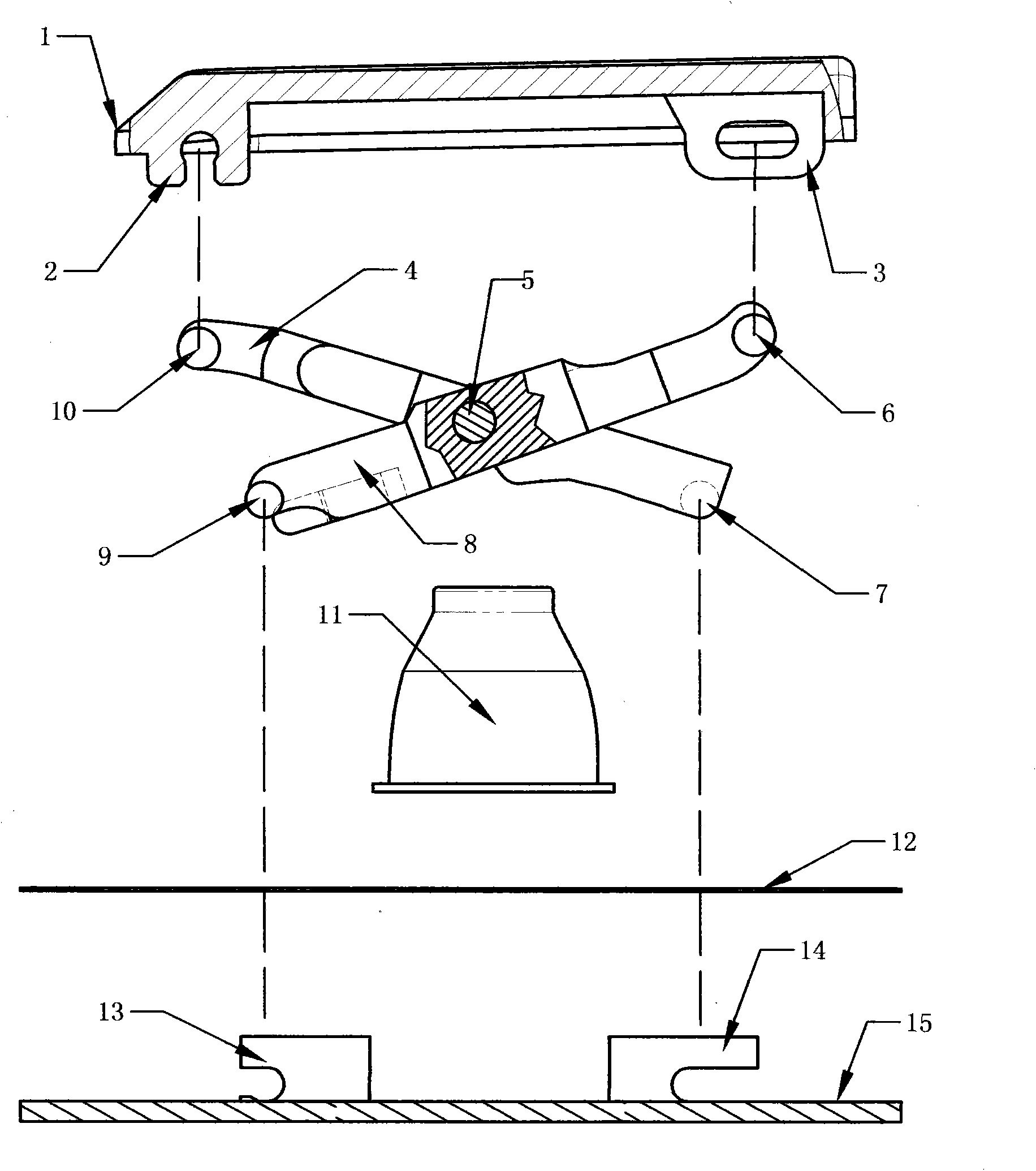

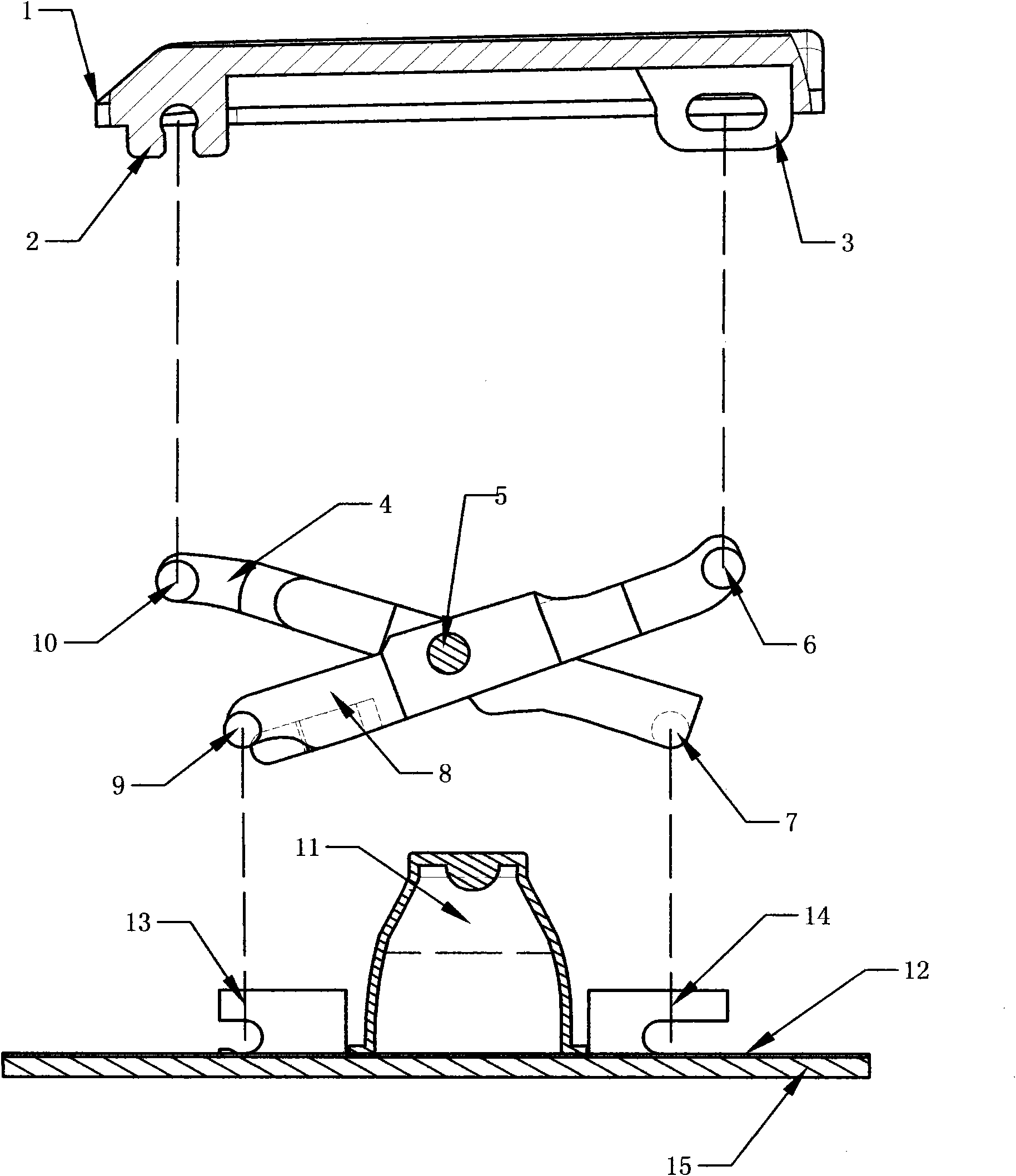

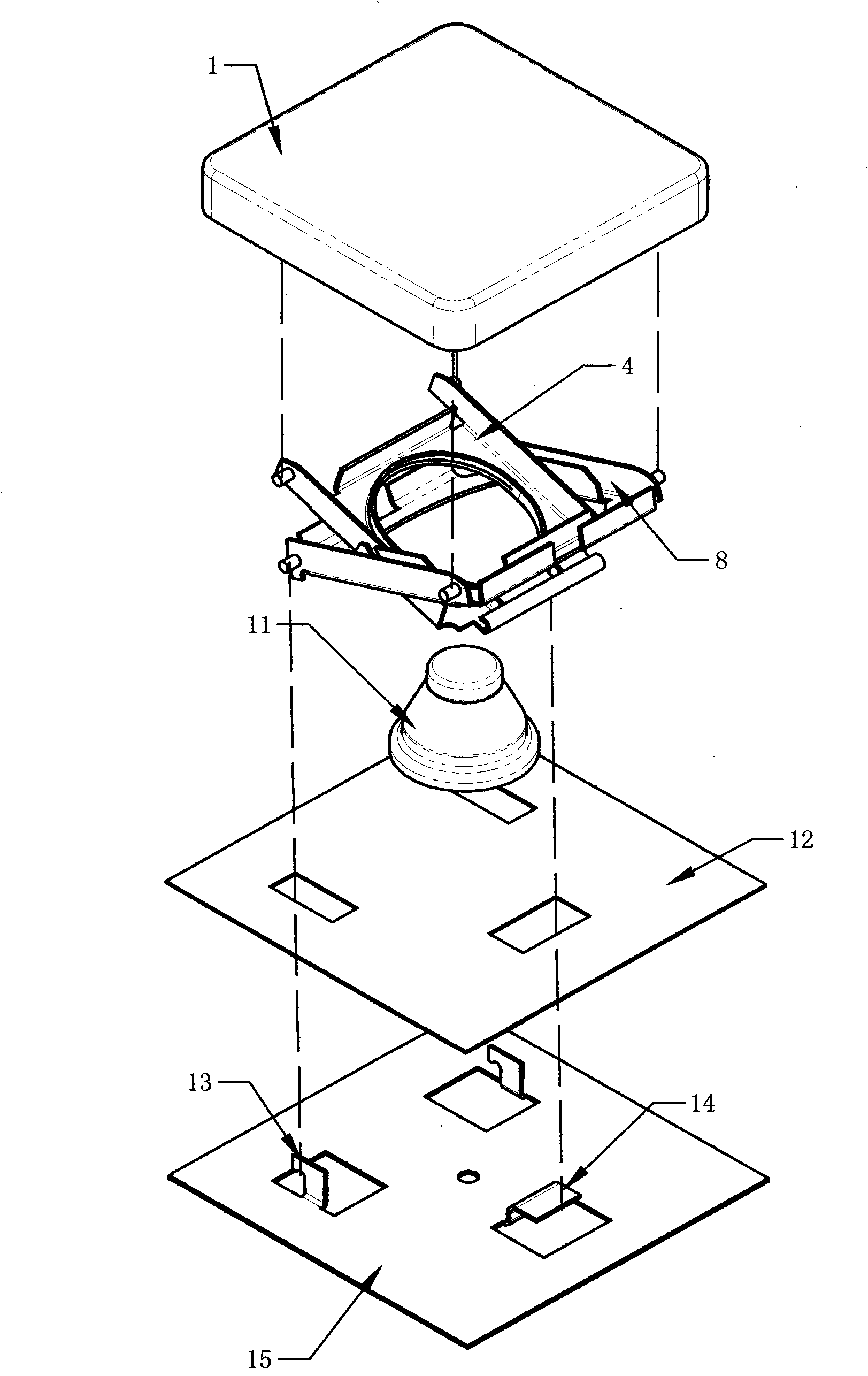

[0116] see image 3 , The sheet metal connecting rod structure of the present invention is made of keycap 1, rubber elastic ring 11, support plate 15, membrane switch sheet 12, inner connecting rod 4, outer and inner connecting rod 8.

[0117] see figure 1 , figure 2 , image 3 1. The keycap 1 is in the shape of a traditional keycap. There is a keycap connection part on the concave bottom surface of the keycap 1 . The keycap connection part is composed of a sliding part 3 and a rotating part 2 .

[0118] see Figure 4 1. There is an inner connecting rod through hole 16 near the middle part of the inner connecting rod plate surface 18 of the inner connecting rod 4, and there is a flanging and bending edge 17 along the edge of the inner connecting rod through hole 16, and on the left and right sides of the flanging and bending edge 17 There is an inner connecting rod bending edge 19 perpendicular to the inner connecting rod plate surface 18, and an upper hinge shaft 10 is a...

Embodiment 2

[0135] see Figure 18 1. There is an inner connecting rod through hole 16 near the middle part of the inner connecting rod plate surface 18 of the inner connecting rod 4, and there is a flanging and bending edge 17 along the edge of the inner connecting rod through hole 16, and on the left and right sides of the flanging and bending edge 17 There is an inner connecting rod bending edge 19 perpendicular to the inner connecting rod plate surface 18,

[0136] There is an inner sliding shaft 7 on the upper outer side of the bending edges 19 of the two inner connecting rods. The inner sliding shaft 7 directly stretches the circular boss on the plate surface or directly before the bending edges 19 of the two inner connecting rods are bent. It is fixed on the board by automatic riveting, welding and other processes. There is 21 of inner connecting rod giving way space below flanging bending edge 17.

[0137] see Figure 19 1. The support plate 15 formed with the support plate rota...

Embodiment 3

[0145] see Figure 21 , Figure 22 1. Near the middle part of the outer link plate surface 22 of the outer link 8, there is an approximate outer link through hole 23, and there is an upper flange 33 on the outer link above the outer link through hole 23, and the upper flange 33 of the outer link is oblique Upwards, the outer upper sliding shaft 6 that protrudes left and right symmetrically is formed at its end, and the outer upper sliding shaft 6 is formed by the process of flanging 33 end coils on the outer connecting rod.

[0146] All the other are the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com